Tire central inflation and deflation automatic control system and method

An automatic control system, central control technology, applied in tire measurement, tire parts, transportation and packaging, etc., can solve the problems of long pressure measurement time, unfavorable battlefield survival, difficult layout, etc., to ensure safety and stability, The effect of improving driving experience and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

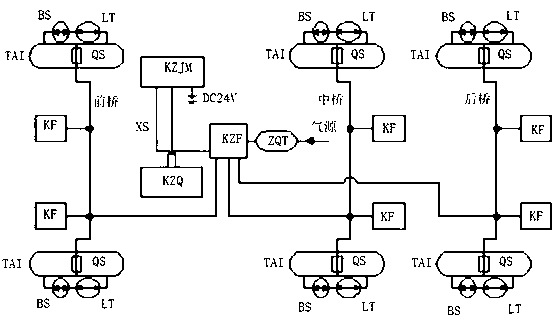

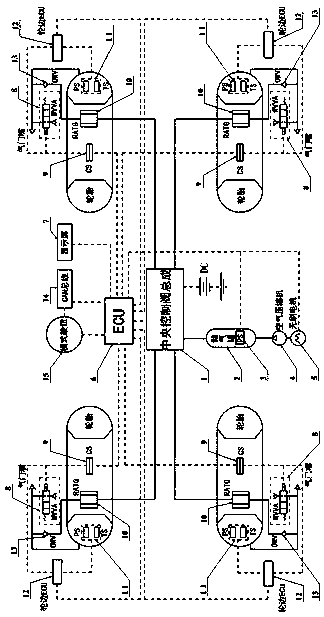

[0049] The embodiment of the tire central inflation and deflation automatic control system of the present invention is as follows:

[0050] The mode knobs commonly found in military wheeled vehicles have multiple modes such as mud / sand / snow, road, and off-road. Under mud / sand / snow working conditions, the larger the tire contact area, the stronger the vehicle adhesion and the better the passability. Therefore, in this case, the tire pressure should be lowered. When the driver selects the driving mode through the mode knob, the tire central inflation and deflation automatic control system (ACTIS) of the present invention will judge according to the vehicle speed signal, wheel speed signal, vibration acceleration signal, etc. Whether it is possible to execute the deflation command, and if yes, adjust the tire pressure to the preset tire pressure value under mud / sand / snow conditions. When the vehicle enters the road after leaving the mud / sand / snow condition, the vehicle speed inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com