An automatic palletizing machine and automatic palletizing method applied to feed packaging bags

A feed bag and palletizer technology, applied in the field of packaging equipment, can solve the problems of low efficiency of manual palletizing, high manufacturing cost and high labor cost, and achieve the effect of high degree of automation, low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Carry out detailed explanation below in conjunction with embodiment:

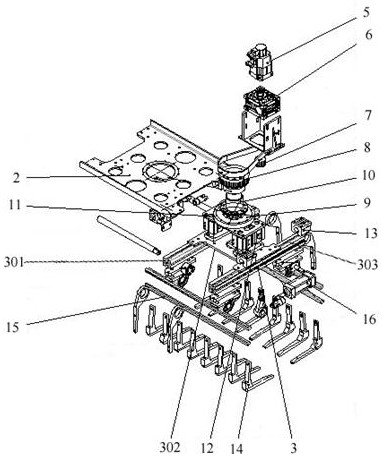

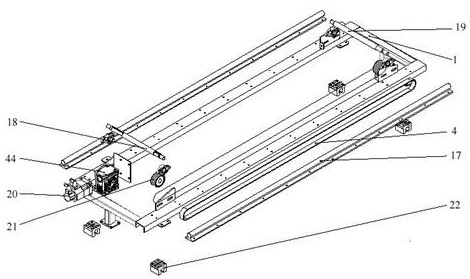

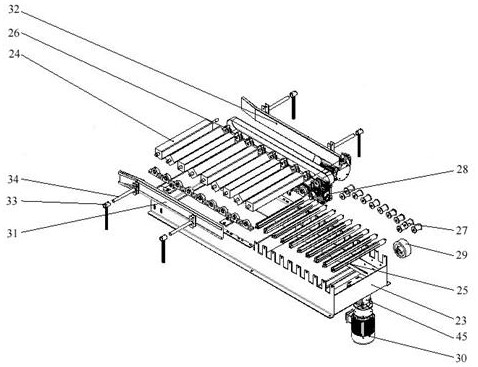

[0015] An automatic palletizer applied to feed packaging bags, including a main frame, a tray conveying mechanism, a driving tray lifting mechanism, a feed bag shaping mechanism and a palletizing mechanism, and the feed bag shaping mechanism is installed on the upper left side of the main frame , used to realize the vibration of the feed pack, so that the feed pack is stable and tidy; the palletizing mechanism is set on the top of the main frame, used to grab the feed pack processed by the feed pack shaping mechanism, and put the feed pack into the tray On the conveying mechanism; the pallet conveying mechanism is installed on the bottom of the main frame, used to carry the palletized feed packages, and transport the palletized feed packages out of the automatic palletizer; the driving pallet lifting mechanism is located on Below the pallet conveying mechanism, it is used to adjust the level of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com