Thermal shaping method for structural part containing plastic

A technology for thermal shaping and structural parts, which is applied in the field of material processing, and can solve problems such as the need for improvement in shaping methods, high flatness, and springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

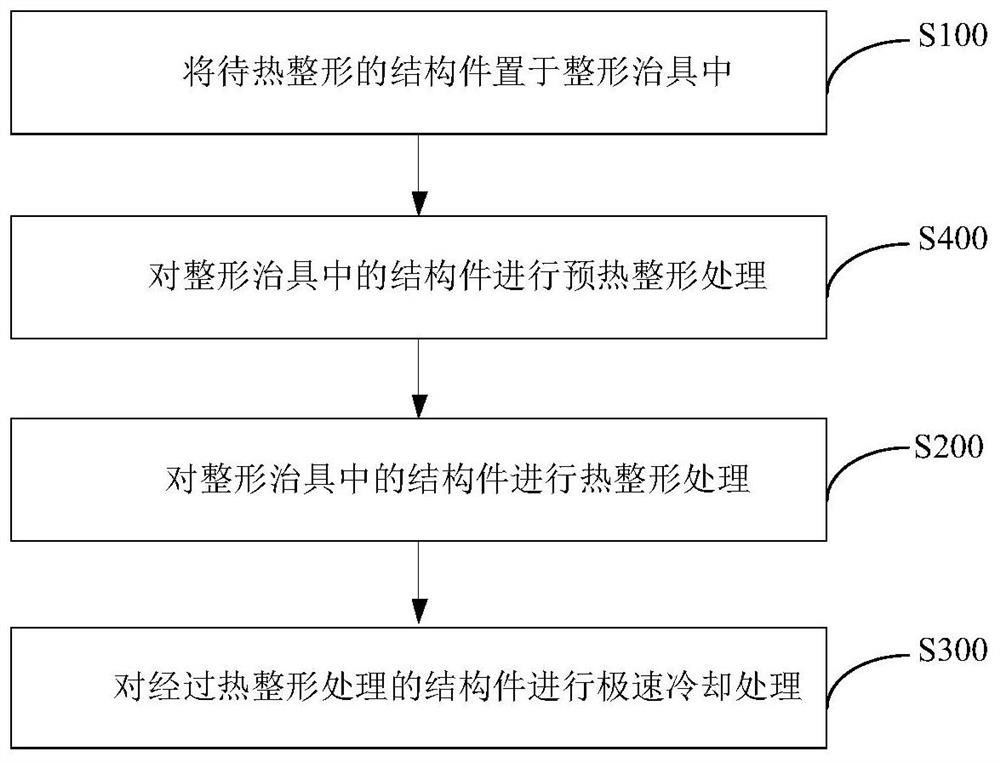

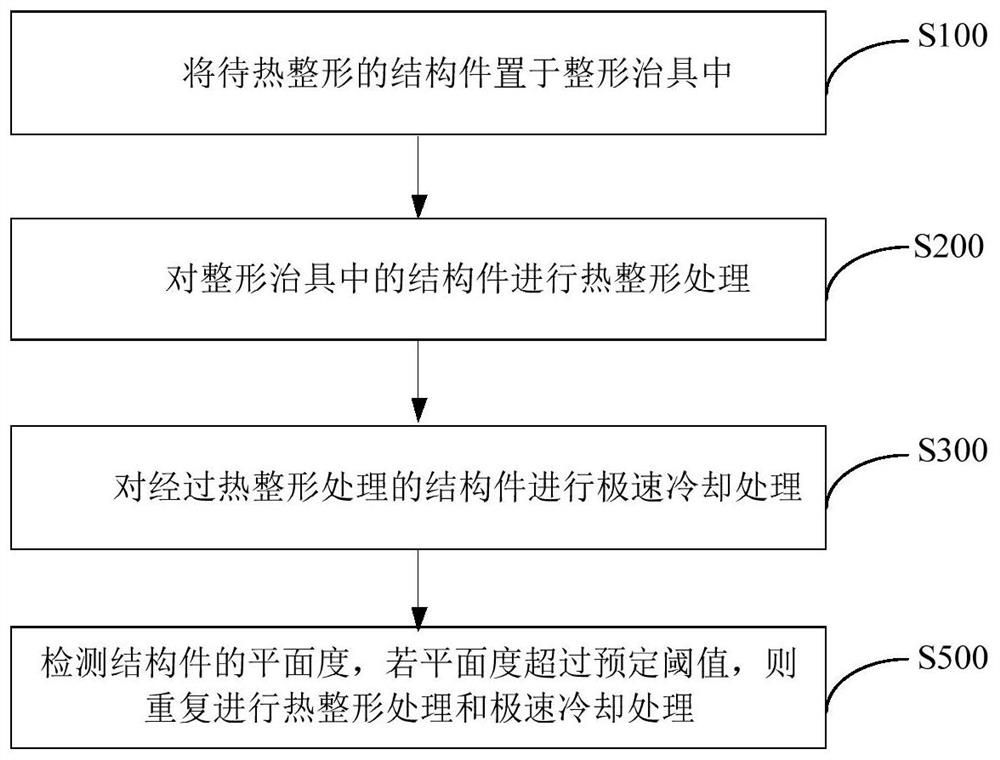

[0040] A thermal shaping method for a structural part containing plastic, comprising: placing the structural part to be thermally shaped in a shaping jig (the shaping jig is a stainless steel mobile phone back shell jig, consisting of upper and lower layers , the upper layer is an inner cavity profiling structure, the lower layer is a back profiling structure, and the structural size accuracy is ±0.02mm); the structural parts in the plastic shaping fixture are preheated and shaped (the preheating temperature is 70°C ; The preheating time is 30min; the preload is 3MPa); the structural parts in the shaping fixture are subjected to heat shaping treatment (the heat shaping temperature is 140°C; the heat shaping time is 40min; the load is 7MPa); The structural member that has undergone the heat shaping treatment is subjected to cooling treatment, and the cooling rate of the cooling treatment is 5K / s (the cooling medium is dry ice; the cooling temperature is -50° C.; the cooling time...

Embodiment 2

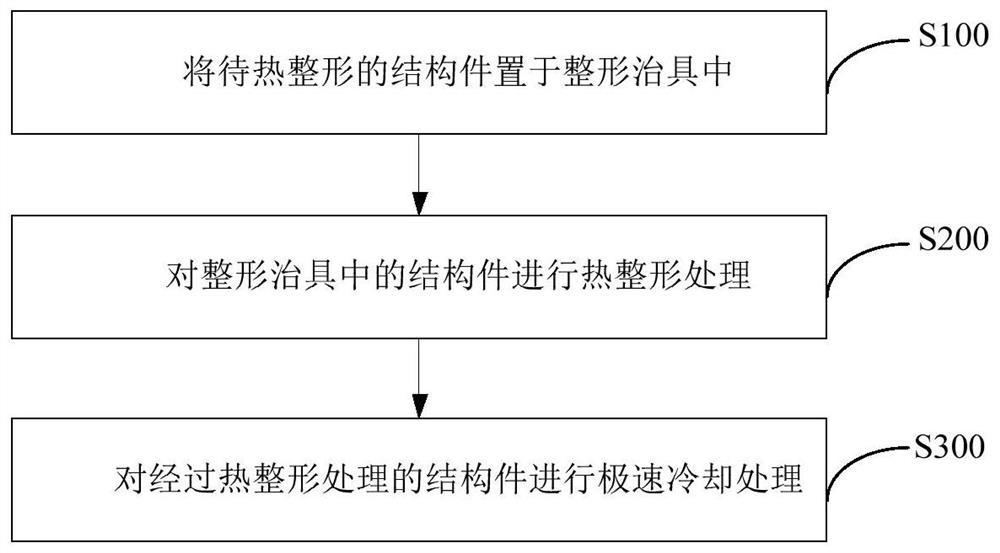

[0043] A thermal shaping method for a structural part containing plastic, comprising: placing the structural part to be thermally shaped in a shaping jig (the shaping jig is a stainless steel mobile phone back shell jig, consisting of upper and lower layers , the upper layer is an inner cavity profiling structure, the lower layer is a back profiling structure, and the structural size accuracy is ±0.02mm); the structural parts in the plastic shaping fixture are subjected to heat shaping treatment (the heat shaping temperature is 140°C; The thermal shaping time is 40min; the load is 7MPa); the structural parts that have undergone the thermal shaping treatment are cooled, and the cooling rate of the cooling treatment is 5K / s (the cooling medium is dry ice; the cooling temperature is -50°C ; Cooling time is 10min).

[0044] Table 2 shows the flatness test results of the structural member before and after it is processed by the thermal shaping method.

Embodiment 3

[0046] A thermal shaping method for a structural part containing plastic, comprising: placing the structural part to be thermally shaped in a shaping jig (the shaping jig is a stainless steel mobile phone back shell jig, consisting of upper and lower layers , the upper layer is an inner cavity profiling structure, the lower layer is a back profiling structure, and the structural size accuracy is ±0.02mm); the structural parts in the plastic shaping fixture are preheated and shaped (the preheating temperature is 70°C ; The preheating time is 30min; the preload is 3MPa); the structural parts in the shaping fixture are subjected to heat shaping treatment (the heat shaping temperature is 140°C; the heat shaping time is 40min; the load is 7MPa); The structural member that has undergone the heat shaping treatment is subjected to cooling treatment, and the cooling rate of the cooling treatment is 5K / s (the cooling medium is dry ice; the cooling temperature is -80° C.; the cooling time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com