A kind of coal gangue recycled slope protection brick and its preparation method

A technology of coal gangue and slope protection bricks, which is applied in the field of coal gangue regeneration slope protection bricks and its preparation, can solve the problems of shortened demoulding and curing time, easy collapse, etc., achieves shortening of demoulding and curing time, improves early strength, and promotes cement hardening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

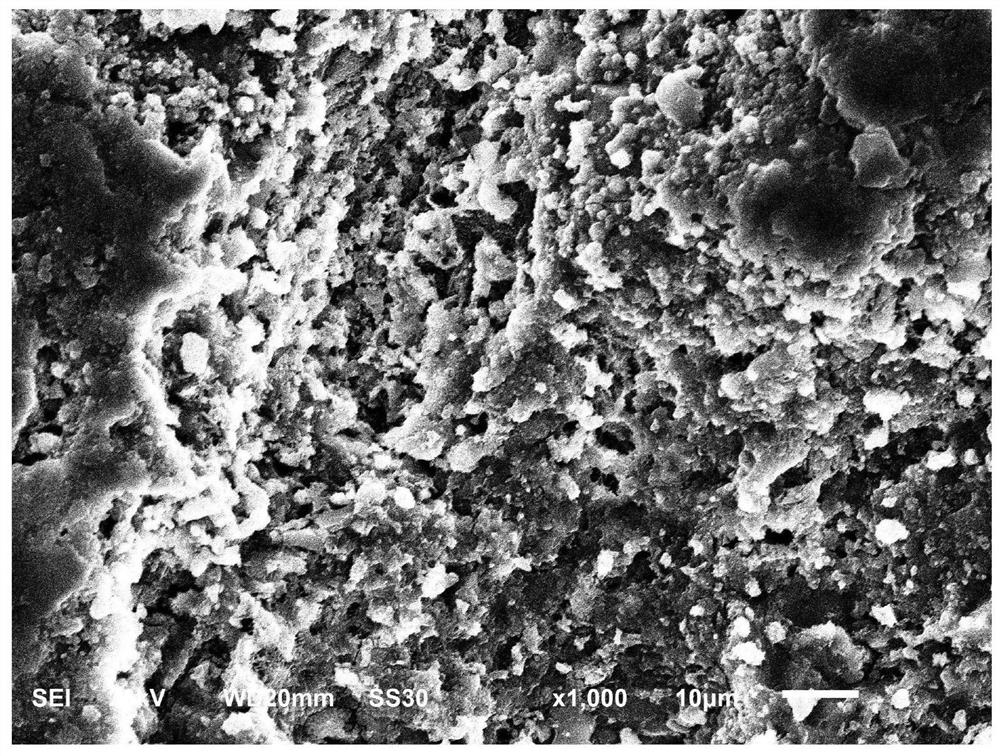

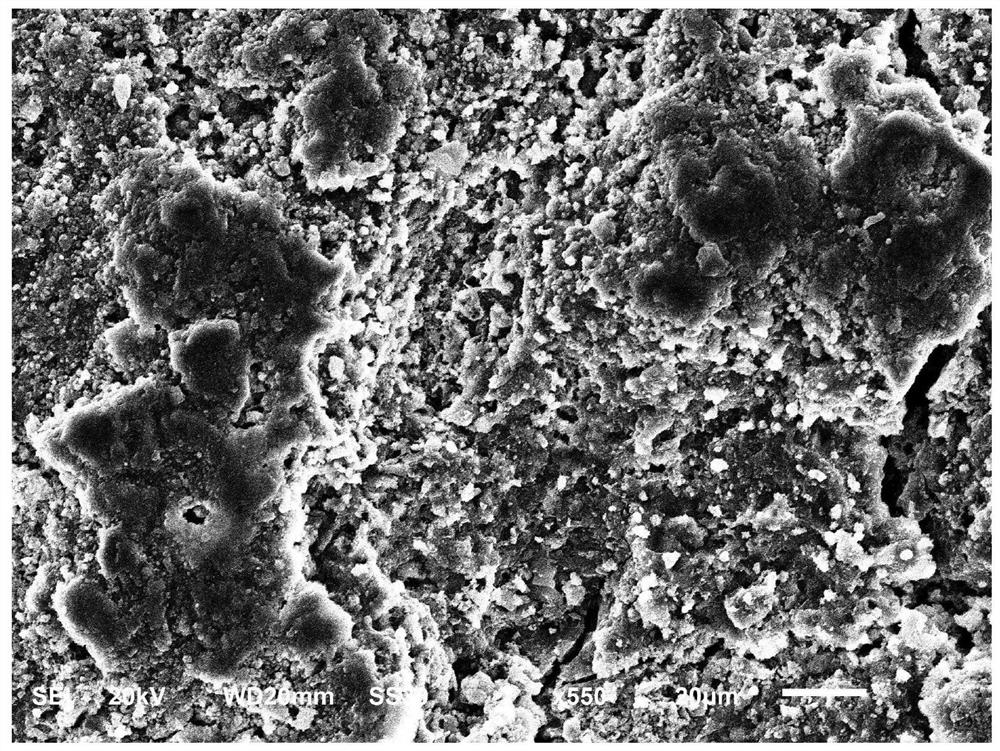

Image

Examples

Embodiment 1

[0032] 1. A coal gangue recycled slope protection brick, comprising the following raw materials in parts by weight: 350 parts of cement, 350 parts of stone powder, 300 parts of uncalcined coal gangue, 3.5 parts of accelerator (sodium hexametaphosphate), 3.7 parts of aluminum powder, 0.5 parts of thickener (gypsum), 19.5 parts of early strength agent (calcium sulfate), 10 parts of additives; the additive is a mixture of ethylene glycol and triethanolamine, wherein the mass ratio of ethylene glycol: triethanolamine is 15.5:1 .

[0033] 2, the preparation method of described coal gangue regeneration slope protection brick comprises the following steps:

[0034] Step 1. Weigh the raw materials according to the formula, add the weighed cement, stone powder and uncalcined coal gangue into the stirring tank, stir and mix to obtain a mixed slurry;

[0035] Step 2, first add the accelerator to the mixing slurry, stir, then add the early strength agent and additives in turn, add a part...

Embodiment 2

[0038] A kind of coal gangue recycled slope protection brick, comprising the following raw materials in parts by weight: 300 parts of cement, 300 parts of stone powder, 250 parts of uncalcined coal gangue, 2 parts of accelerator (sodium hexametaphosphate), 2 parts of aluminum powder, thickening 0.1 part of agent (sodium dodecylsulfonate), 10 parts of early strength agent (sodium sulfate), 2 parts of additives; the additive is a mixture of ethylene glycol and triethanolamine, wherein the mass ratio of ethylene glycol: triethanolamine It is 12:0.5. The preparation method of the gangue recycled slope protection brick is the same as that in Example 1.

Embodiment 3

[0040] A kind of coal gangue recycled slope protection brick, comprising the following raw materials in parts by weight: 400 parts of cement, 400 parts of stone powder, 350 parts of uncalcined coal gangue, 5 parts of accelerator (sodium hexametaphosphate), 5 parts of aluminum powder, thickening 1 part of agent (ethoxylated alkyl sodium sulfide), 30 parts of early strength agent (potassium sulfate), 18 parts of additive; the additive is a mixture of ethylene glycol and triethanolamine, wherein ethylene glycol: the mass of triethanolamine The ratio is 18:2. The preparation method of the gangue recycled slope protection brick is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com