Post-pouring belt structure for outer wall of basement and construction method thereof

A technology for basement exterior walls and post-casting belts, which is applied to underwater structures, infrastructure projects, artificial islands, etc., can solve the problems of limited brick laying height, long construction period, difficult operation, etc., and achieves simplified construction steps, The effect of reducing construction difficulty and improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

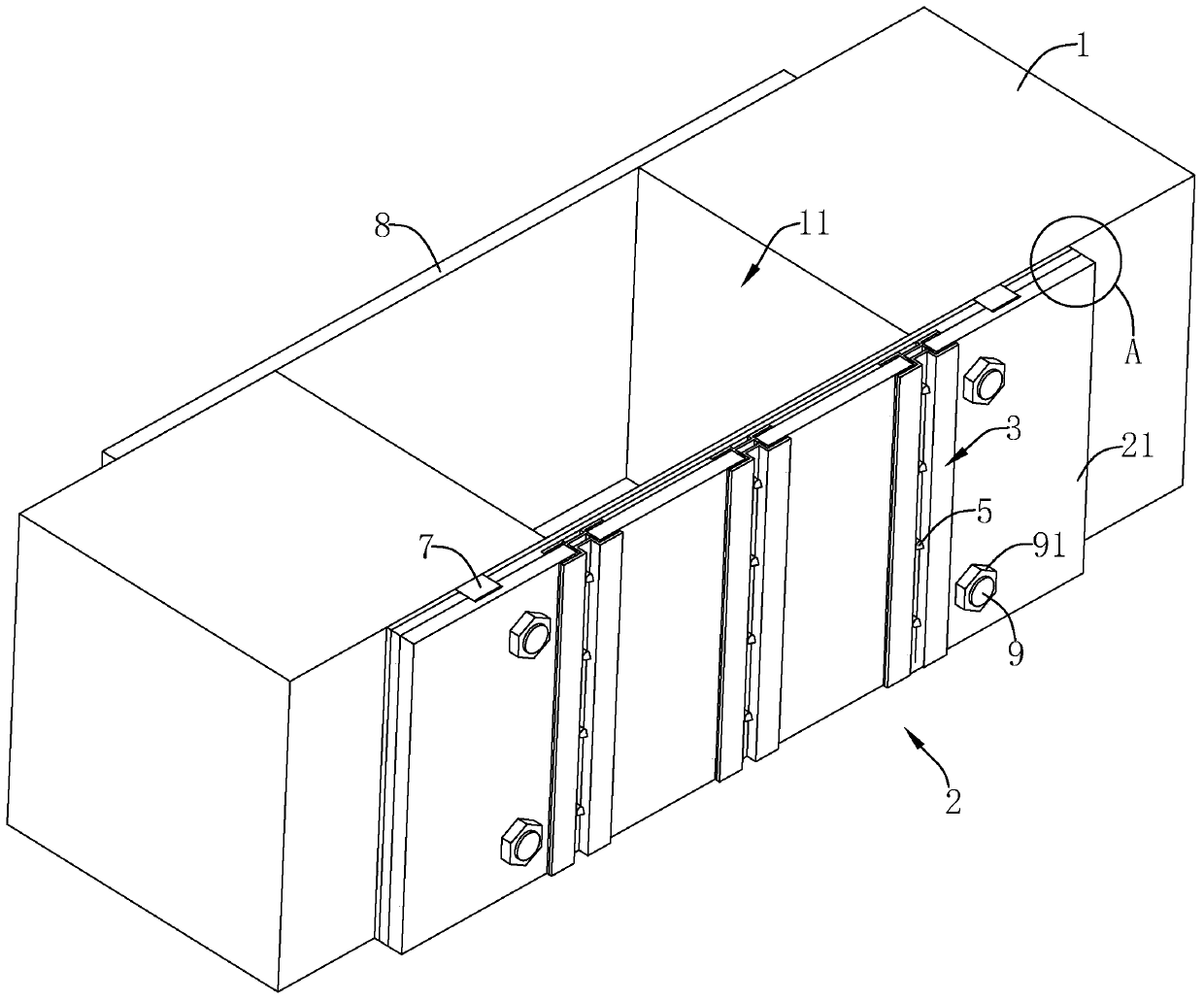

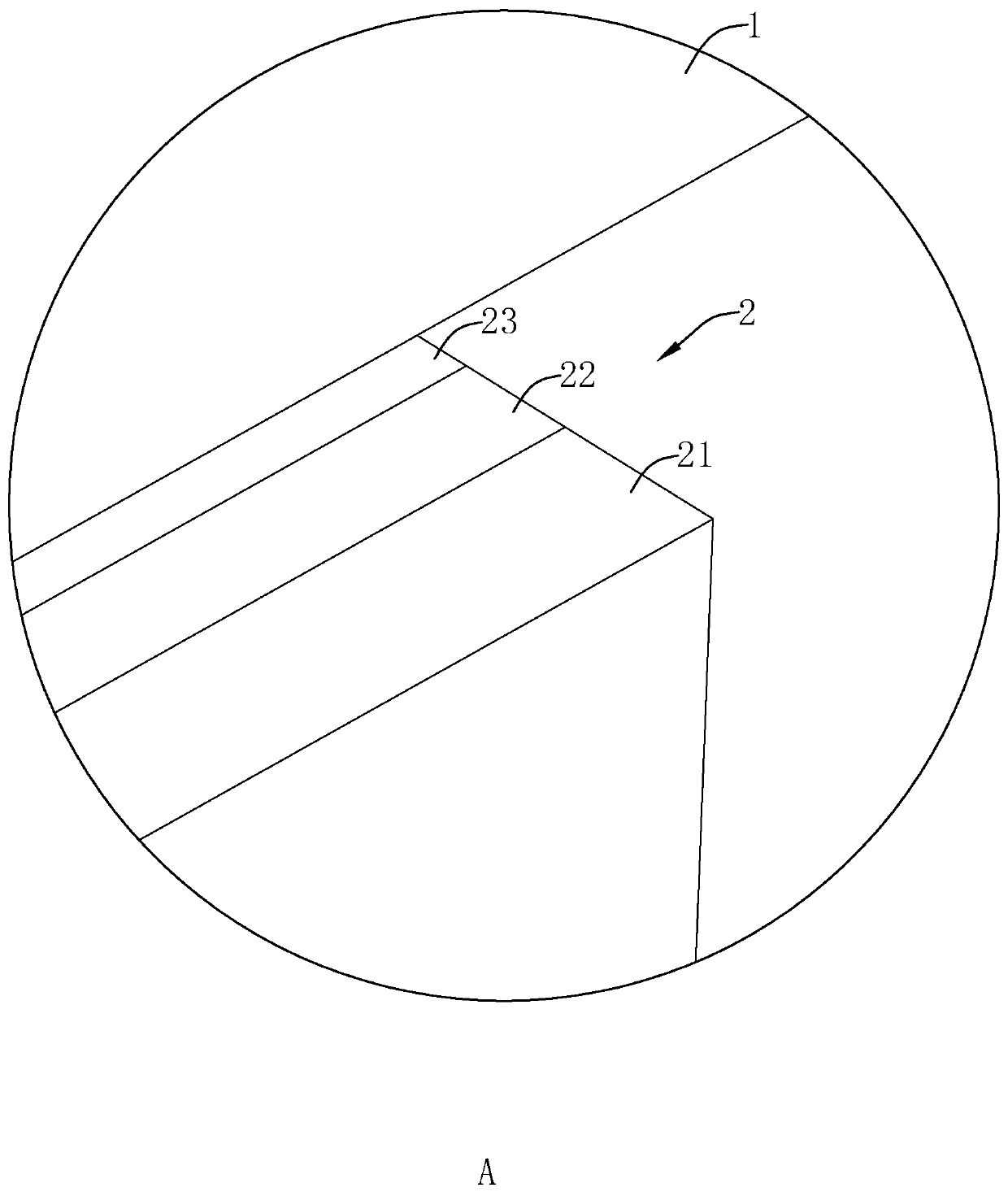

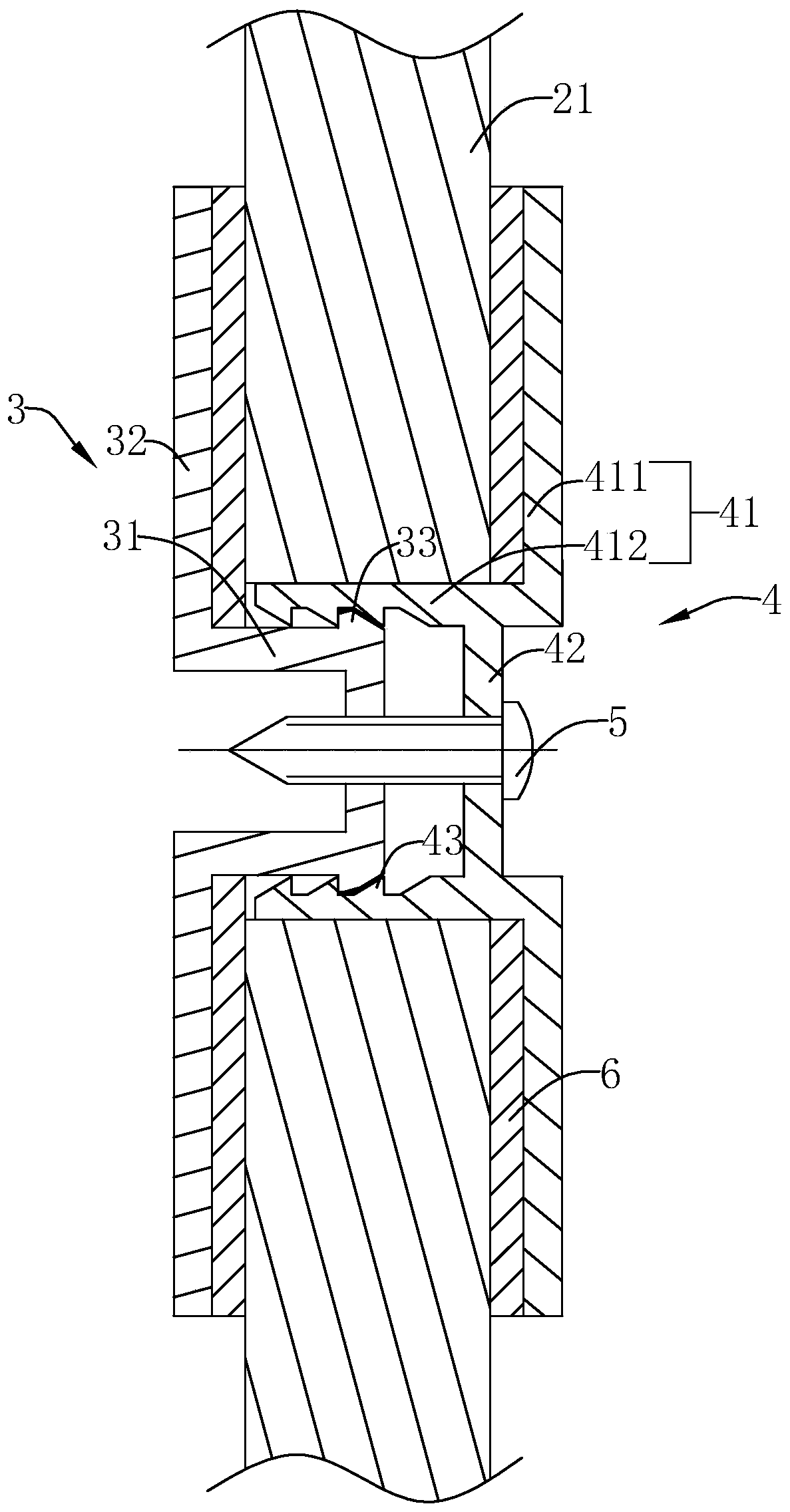

[0039] refer to figure 1 , is a basement exterior wall post-cast belt structure disclosed in the present invention, comprising a basement exterior wall 1 and a post-cast strip 11 arranged on the basement exterior wall 1, and a prefabricated board 2 is arranged on the outside of the basement exterior wall 1, and its length is greater than The post-cast tape 11 is used to isolate the post-cast tape 11 from the outside, so as to protect the post-cast tape 11 . The prefabricated panel 2 includes a plurality of fixed panels 21 of the same size, and there is a connection between the adjacent fixed panels 21. According to the needs of the construction, the staff can choose to install the prefabricated panel 2 and transport it to the construction site. After being operated or transported to the construction site, on-site installation is carried out, and the prefabricated panels 2 are divided into multiple fixed panels 21, which can facilitate the processing and transportation of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com