A water plugging and fracturing method for high water cut old wells in low permeability oil and gas fields

A technology for oil and gas fields and water fracturing, which is applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc. It can solve problems such as small effective range of fractures, failure to divert fractures, and water flooding of oil well fractures. To achieve the effects of expanding the effective range of action, improving production efficiency and benefits, and stabilizing production for a long period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

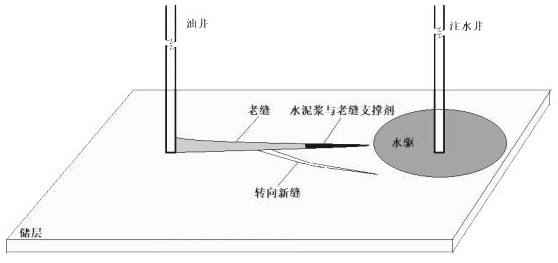

[0031] A method for water plugging and fracturing of old wells with high water content in low-permeability oil and gas fields: use a cement truck to inject cement slurry into the formation, and then use a fracturing vehicle to inject high-viscosity suspended sand fluid into the formation with a low displacement, so that the original fractures in the formation fractures The proppant is suspended, and the cement slurry is pushed to the end of the fracture together, and finally the surfactant fracturing fluid is injected with a large displacement for fracturing construction. The initial setting time of the cement slurry is 6 to 7 hours.

[0032] The cement slurry is made by mixing 50%~70% G grade cement, 28%~49.5% clear water and 0.5~2.0% retarder according to the above mass ratio.

[0033] The high-viscosity suspension liquid is composed of 3.5%~4.0% oligoaminosuccinic acid fatty acid ester salt, 0.4%~0.5% formic acid, 1.0%~2.0%KCl and 93.5%~95.1%H 2 O is mixed according to the ...

Embodiment 2

[0036] A water plugging and fracturing method for high water-cut old wells in low-permeability oil and gas fields, comprising the following steps:

[0037] The first step: preparation before fracturing construction, prepare cement slurry, high-viscosity suspended sand fluid and surfactant fracturing fluid;

[0038] Step 2: Start the construction, first use active water to test the extrusion, check the sealing situation and judge whether the oil layer absorption meets the requirements;

[0039] Step 3: After the test extrusion meets the requirements, inject the cement slurry into the formation with a cement truck; the initial setting time of the cement slurry is 6 to 7 hours;

[0040] Step 4: Use the fracturing truck to pump high-viscosity suspended sand fluid into the formation with low displacement; suspend the original proppant in the formation fracture, and push the cement slurry to the end of the fracture;

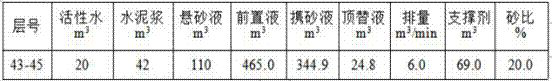

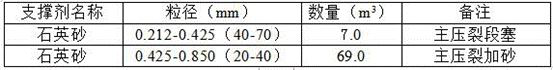

[0041] Step 5: Replace the high-viscosity suspended sand fluid w...

Embodiment 3

[0051] It is basically the same as Example 2, except that the cement slurry is mixed with 70% G grade cement, 28% clear water and 2.0% retarder according to the above mass ratio.

[0052] The suspension liquid of described high viscosity is made of 4.0% oligoaminosuccinic acid fatty acid ester salt, 0.5% formic acid, 2.0%KCl and 93.5%H 2 O is mixed according to the above mass ratio.

[0053] The surfactant fracturing fluid is composed of 4.0% oligomeric aminosuccinic acid fatty acid ester salt, 0.5% formic acid, 2.0% KCl and 93.5% H 2 O is mixed according to the above mass ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com