Water plugging and acidification joint operation method for high-water-cut oil well in low-permeability oil field

A technology for water plugging and joint operation of oil wells, which is applied to earth-moving drilling, wellbore/well components, and production fluids, etc. It can solve problems such as affecting oilfield production efficiency, rising water content of oil wells, and water-flooded production stoppage, and achieve the effect of improving measures. And the effect of efficiency, improving efficiency and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

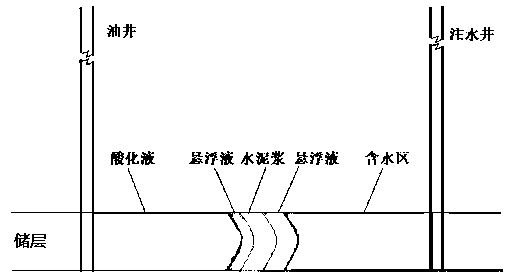

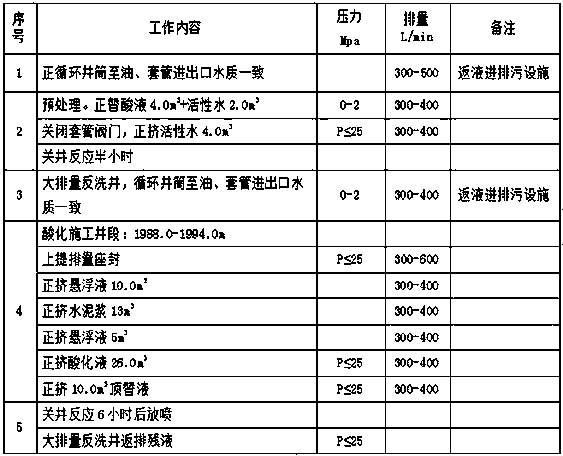

[0027] The combined operation method of water plugging and acidizing of high water content oil wells in low permeability oilfields, first inject a section of high viscosity suspension with a low displacement by a pump truck to push the water fluid in the formation to the rear; then use a cement truck to inject cement slurry into the formation , used to block the water channeling part; then, use a pump truck to inject a section of high-viscosity suspension into the formation to replace the cement slurry to the rear; finally, use a pump truck to pump acidizing liquid into the formation to implement acidification and blockage removal, among which, The initial setting time of cement slurry is more than 6 hours. Among them, the low displacement is 300-400L / min.

[0028] The high-viscosity suspension is composed of 3.5%~4.0% oligoaminosuccinic acid fatty acid ester salt, 0.4%~0.5% formic acid, 1.0%~2.0%KCl and 93.5%~95.1%H 2 O is mixed according to the above mass ratio; the viscosi...

Embodiment 2

[0033] A method for combined operation of water plugging and acidizing in high water-cut oil wells in low-permeability oilfields, comprising the following steps:

[0034] Step 1: Prepare before acidizing construction, prepare cement slurry, acidizing liquid and high-viscosity suspension;

[0035] Step 2: First use a pump truck to inject a high-viscosity suspension with a low displacement to push the water and other fluids in the formation to the rear; at the same time, avoid the acidizing liquid from damaging the cement plugging effect;

[0036] Step 3: Use a cement truck to inject cement slurry into the formation to block the water channeling part; wherein, the initial setting time of the cement slurry is greater than 6 hours;

[0037] Step 4: Use a pump truck to inject a section of high-viscosity suspension into the formation to replace the cement slurry to the rear;

[0038] Step 5: Use the pump truck to transfer and inject the acidizing fluid into the formation, and imple...

Embodiment 3

[0047] Basically the same as embodiment 2, the difference is:

[0048] The high-viscosity suspension is composed of 4.0% oligomeric aminosuccinic acid fatty acid ester salt, 0.5% formic acid, 2.0% KCl and 93.5%%H 2 O is mixed according to the above mass ratio; the viscosity of the high-viscosity suspension liquid at 25°C is greater than 100mPa.

[0049] The cement slurry is mixed with 70% G grade cement, 28% clear water and 2.0% retarder.

[0050] The acidizing solution is formed by mixing 15% hydrochloric acid, 3% fluoboric acid, 2% hydrofluoric acid, 2% corrosion inhibitor for acidification, 1% iron ion stabilizer, 1% clay stabilizer and 76% clear water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com