Hardware-in-the-loop test platform of by-wire control pneumatic brake and testing method thereof

A pneumatic brake and test platform technology, applied in the testing of machine/structural components, vehicle testing, measuring devices, etc., can solve the problems of simulation analysis of the pneumatic brake system that cannot be controlled by wire, independent control of braking force, and braking response Long time and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0079] In order to further set forth the technical scheme of the present invention and its working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

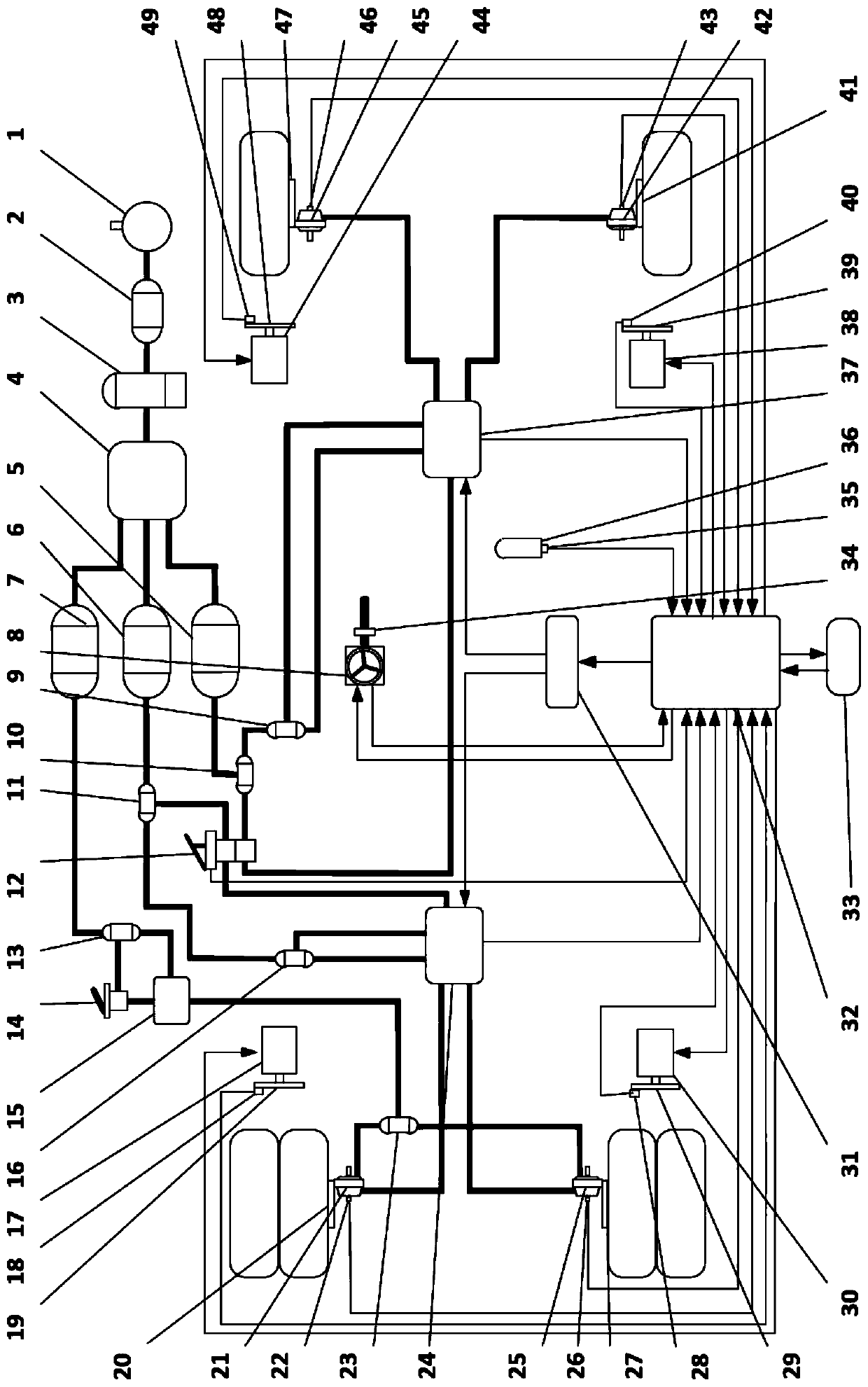

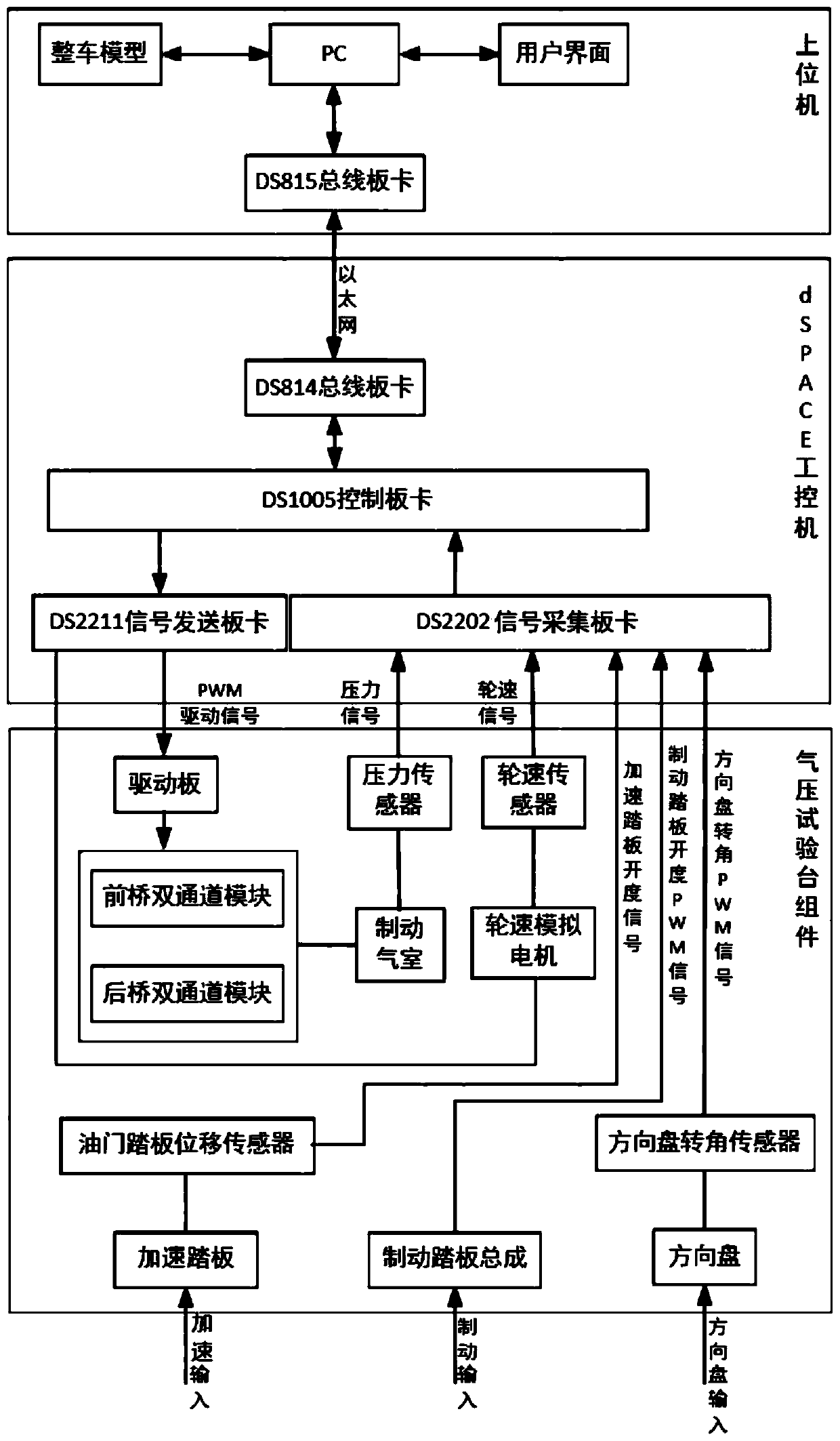

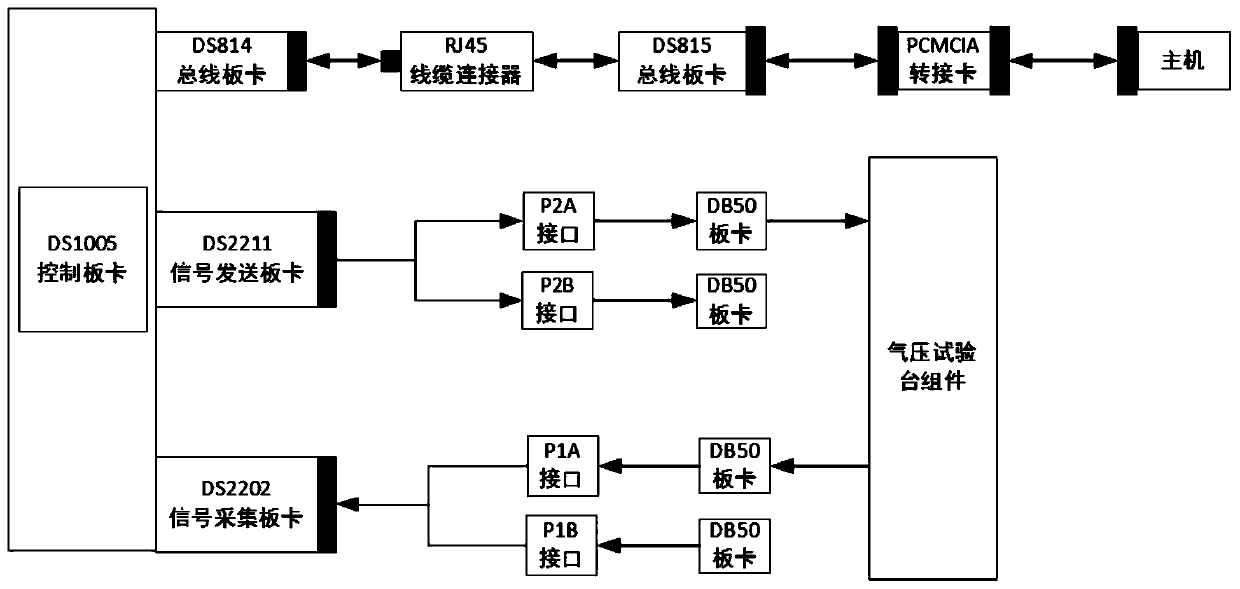

[0080] like figure 1 As shown, the present invention discloses a hardware-in-the-loop test platform for air-by-wire air brakes. The test platform includes: an air source component, an electronically controlled brake system, a traditional brake component, a wheel speed simulation component, a driving control component and a host computer 33.

[0081] The air source assembly includes: air compressor 1, wet air storage tank 2, air dryer 3, four-circuit protection valve 4, front axle brake air storage tank 5, rear axle brake air storage tank 6, parking brake air storage tank 7;

[0082] The electronically controlled braking system includes: dSPACE industrial computer 32, drive module 31, brake master valve 12, front axle dual-channel module 37 and rear axle ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap