Discrete element method-based damping calculation simulation method for a macrostructure of a non-cohesive particle material

A granular material and macro-structure technology, applied in computing, special data processing applications, instruments, etc., it can solve the problem that discrete element software cannot accurately calculate structural damping, etc., and achieve the effect of accurate and effective testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

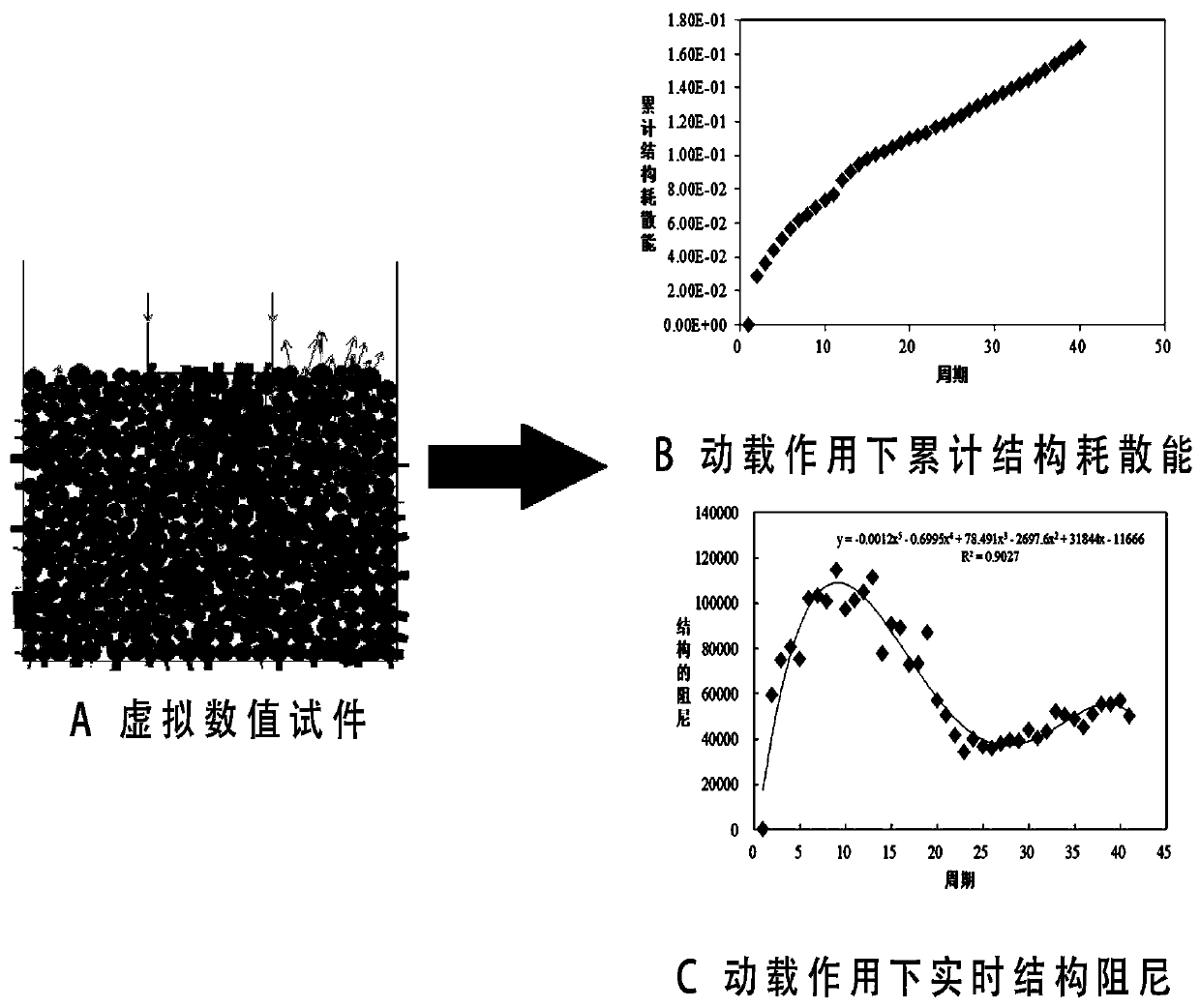

[0028] Such as figure 1 As shown, a method for calculating and simulating macrostructure damping of non-bonded granular materials based on the discrete element method includes the following steps:

[0029] Step 1: Establish a virtual numerical test model, such as figure 1 As shown in (A), the non-cohesive granular material refers to any granular material and structure with elastic characteristics and non-cohesive properties. The particle size is within 30mm, and the internal structure of the material system is The squeezing effect of particles is mainly to form a skeleton structure, and the instability state is mainly caused by sliding friction between particles. The non-cohesive particle materials refer to but not limited to gravel and sand, which are established based on discrete element software PFC Virtual numerical test piece, the size of the test piece is not limited. Three fixed virtual walls are set on the bottom and left and right sides to simulate the test piece cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com