A pcb board surface detection method based on contour tolerance algorithm

A PCB board and outline technology, applied in the field of image processing, can solve the problems of the total number of affected areas, the inability to have enough time to accurately intercept the area, and the selection of the size of the intercepted area cannot be accurately grasped, achieving the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

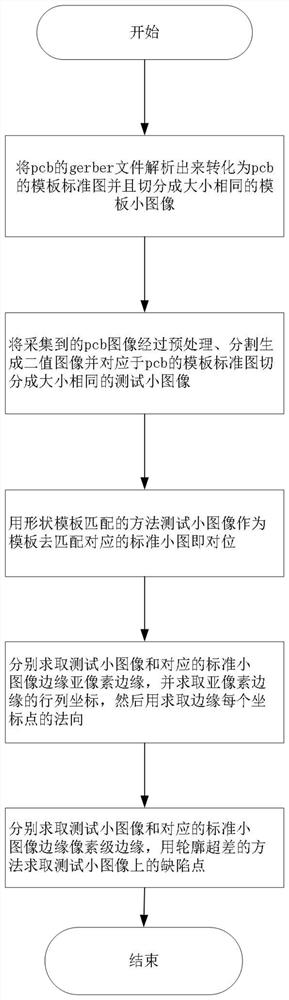

[0033] Embodiment: a method for detecting the surface of a PCB board based on a contour tolerance algorithm.

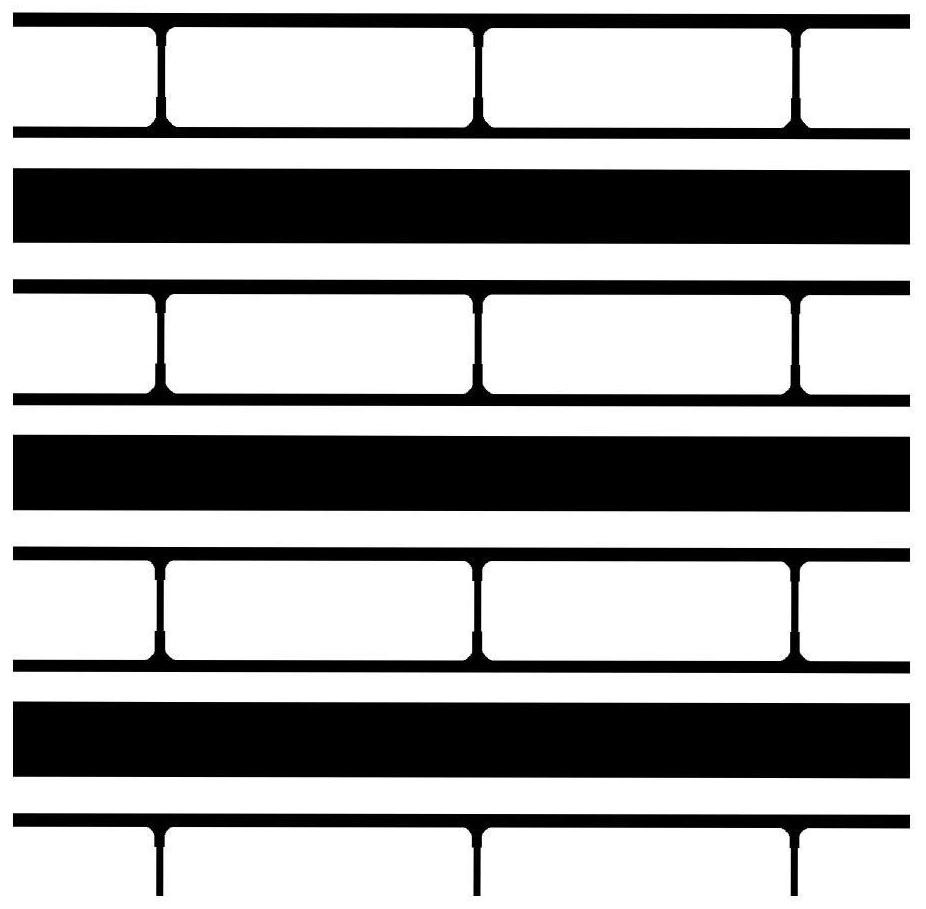

[0034] S1, convert the pcb file into a Gerber file, and then use the GerbMagic software to parse the Gerber file and convert it into a BMP format image; in this way, the binary image of the standard circuit of the pcb bare board is obtained, that is, the standard image, and then cut it into numbers A small image of the same size as a specific size, the segmented standard image is preferentially used to match the object;

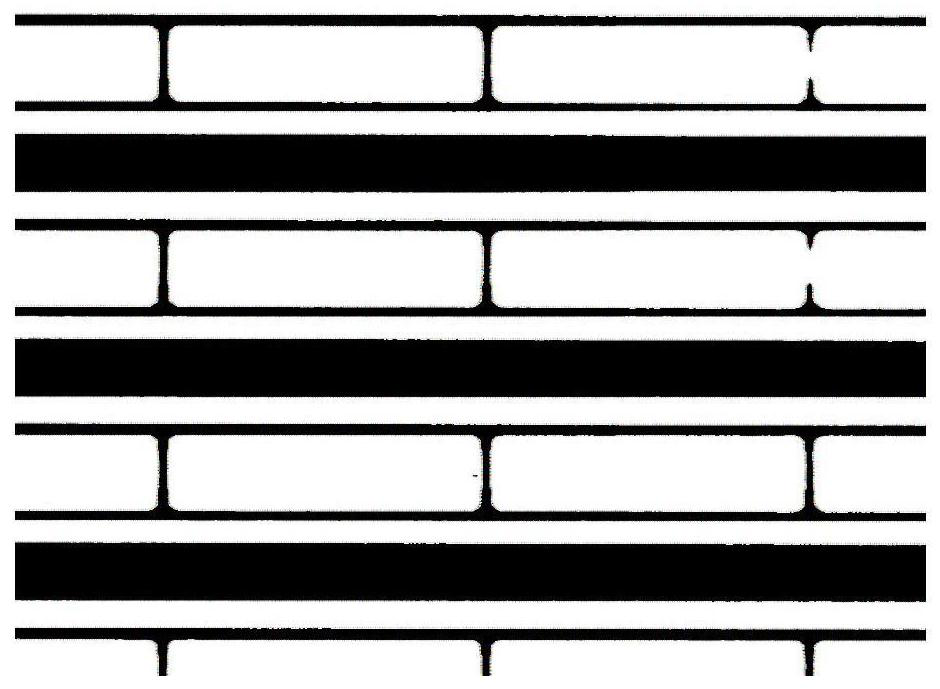

[0035] S2, process the collected image, i.e. denoising, automatic threshold segmentation algorithm to accurately segment the copper surface of the bare board, and then binarize the image, that is, the gray value of the line conductor area is 255, and the gray value of the background area is 0, the binary image is obtained, that is, the test image is divided into several test small images of the same size and specific size, and the divided test small im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com