Method and system for controlling rotor speed of motor

A technology of motor rotor and control method, applied in electrical components, emergency protection circuit devices, etc., can solve the problems of motor power cut off, impeller speed drop, trouble, etc., and achieve the effect of preventing false braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

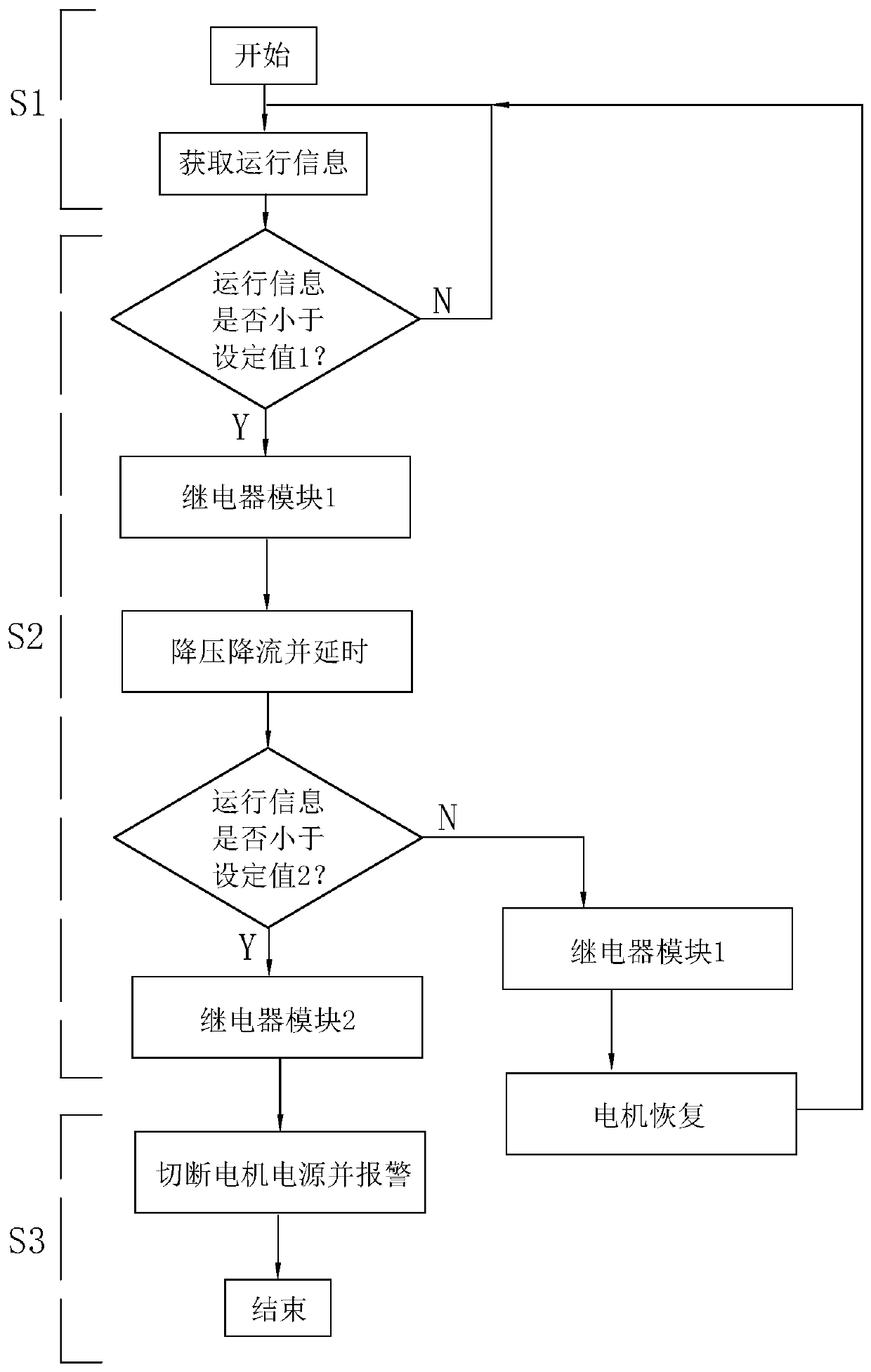

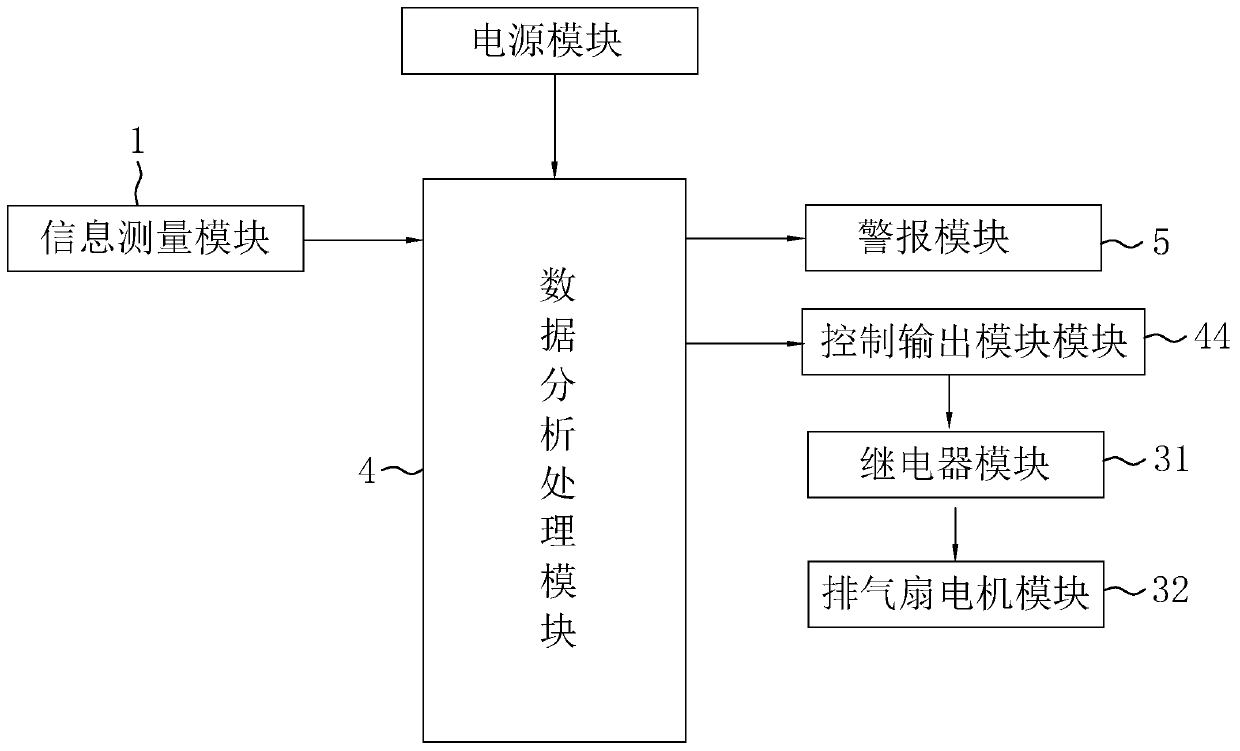

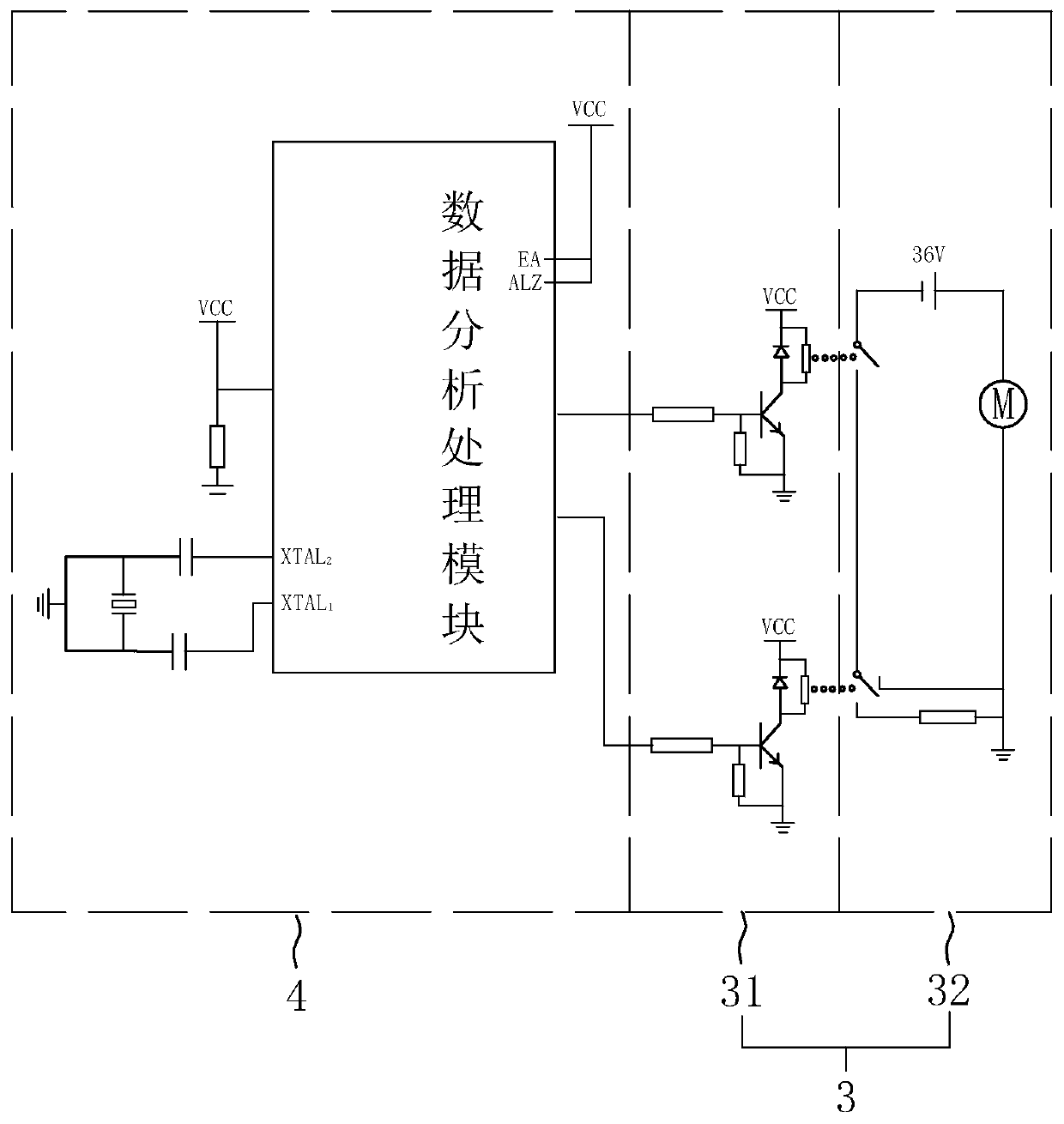

[0066] A method for controlling the rotor speed of a motor, mainly referring to a control method for controlling a DC motor that drives an impeller to rotate, such as a DC motor in a ceiling fan, such as a DC motor that drives an impeller in a chimney, combined with figure 1 and Figure 4 It can be seen that it mainly includes the following steps:

[0067] The first step S1: obtaining the operation information of the motor rotor in real time, the operation information in this embodiment refers to the real-time rotation speed information of the impeller.

[0068] Second step S2: According to the acquired real-time rotation speed information of the impeller, determine whether to cut off the power supply of the motor. Specifically, the analysis method is to compare the obtained rotational speed value with the set value 1, which refers to the normal rated rotational speed value of the motor under the rated voltage / rated current of the motor. When the obtained speed value is equa...

Embodiment 2

[0085] The difference between this embodiment and Embodiment 1 is that the operation information of the motor rotor acquired in S1 is the corresponding current value when the impeller rotates in real time.

[0086] The setting value 1 in S2 refers to the rated current value of the motor, and the setting value 2 in S2 refers to the normal current value of the motor after voltage reduction. By configuring the information detection module 1 as a current value measurement module, the purpose of preventing false braking of the motor is achieved by analyzing the magnitude of the current when the motor is rotating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com