Turning and processing device of bearing inner ring and processing method

A bearing inner ring and turning processing technology, which is applied to auxiliary devices, metal processing equipment, metal processing machinery parts, etc., can solve the trouble of adjusting the verticality of the axis of the inner hole and the front end face, and the poor stability of the verticality of the axis of the inner hole and the front end face , low machining accuracy of the rear end face of the oil groove and the inner ring, etc., to achieve the effect of low cost, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

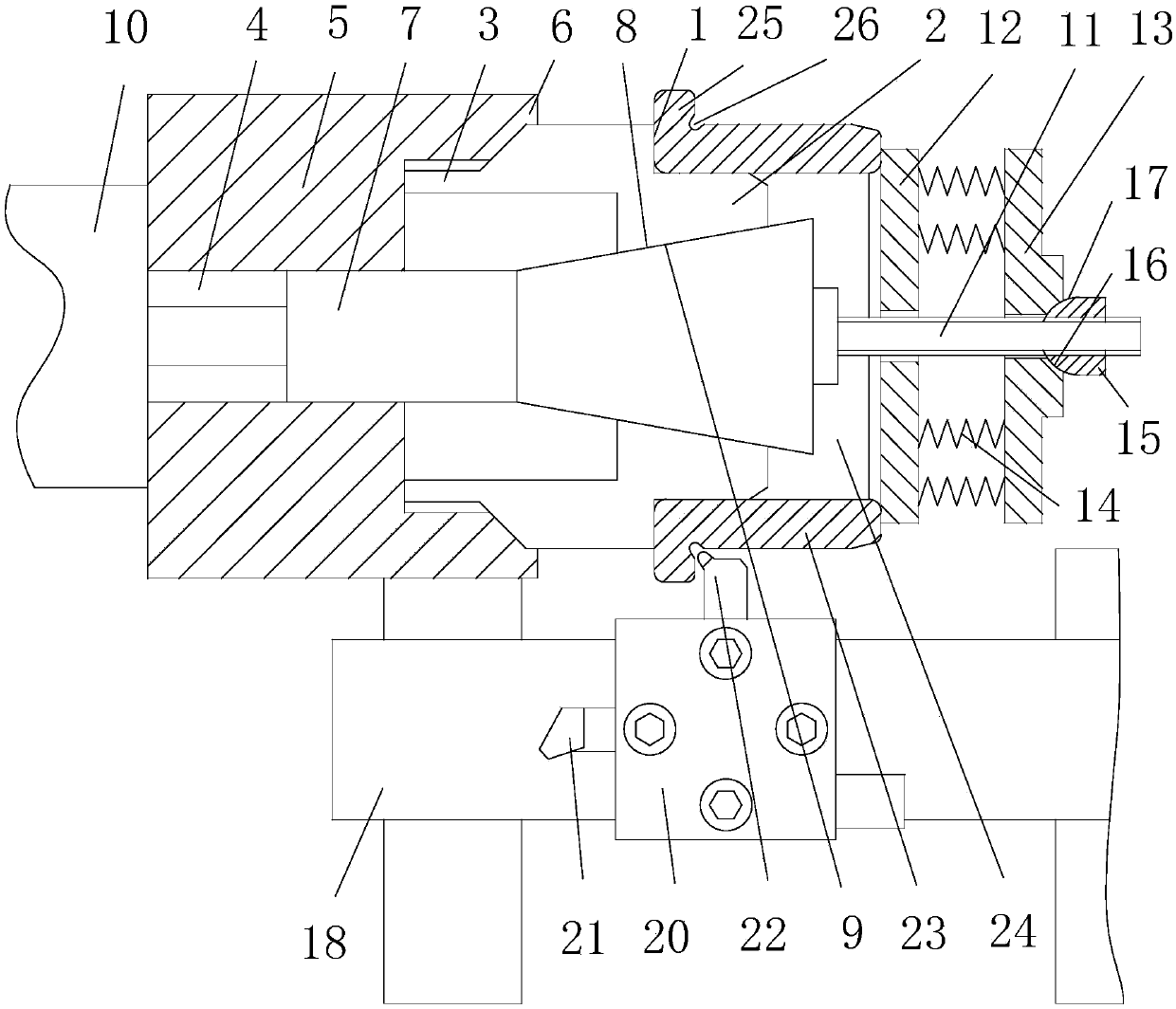

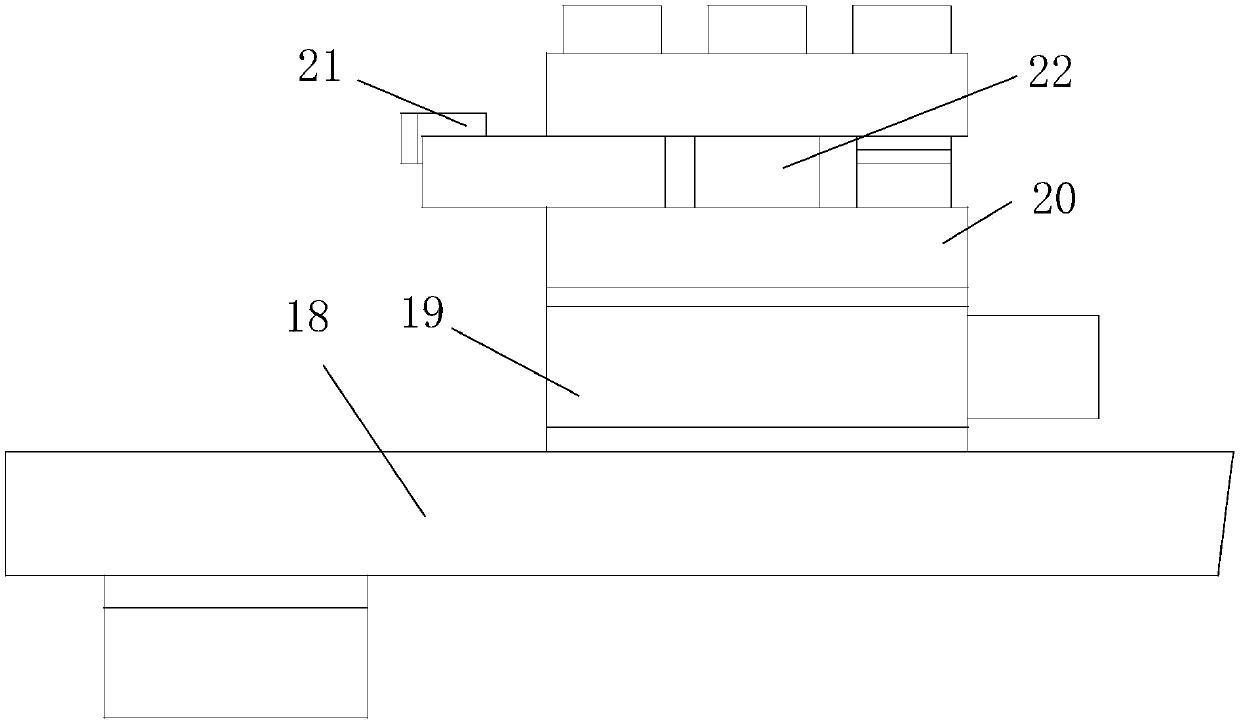

[0021] Embodiment 1, as attached figure 1 , attached image 3 Shown: a bearing inner ring turning processing device, including: turning processing device, inner hole clamping device, bearing inner ring front end position adjustment and stabilization device.

[0022] The inner hole clamping device includes: four inner claw feet 2 provided with a reference retaining surface 1 on the outside, a connecting strip 3 arranged at the rear end of the inner claw feet 2, and an axial through hole 4 is provided and connected to the connecting strip 3. The mounting seat 5 welded at the end is set outside the inner claw foot 2 and integrally formed with the front end of the mounting seat 5 to form a radial limit ring 6 connected to the axial through hole 4 and between the inner claw feet 2 Tensioning rod 7, the tensioning inner cone surface 8 located at the front portion of the tensioning rod 7, the tensioning outer cone surface 9 matched with the tensioning inner cone surface 8 on the inn...

Embodiment 2

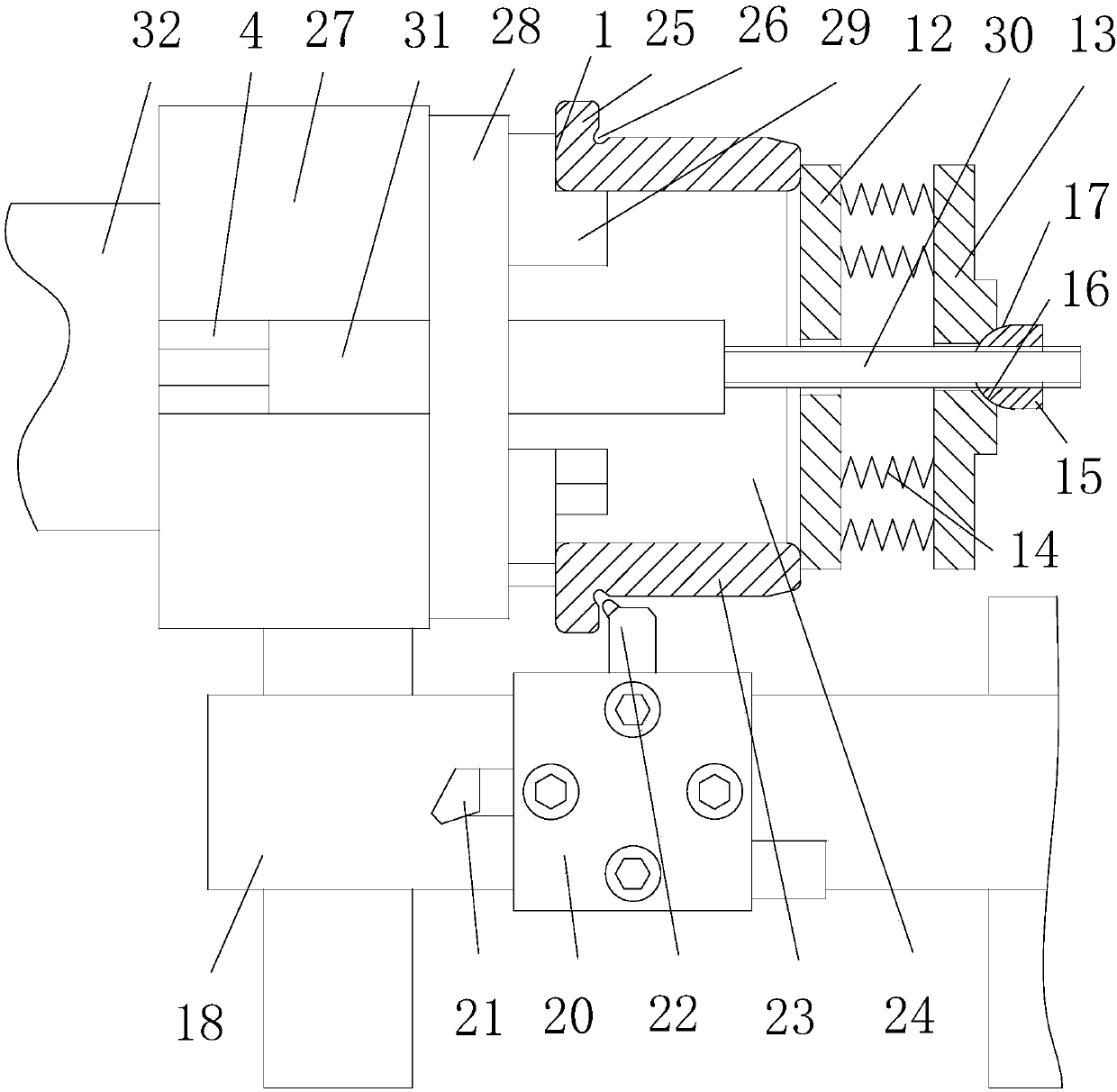

[0026] Embodiment 2, as attached figure 2 , attached image 3 Shown: a bearing inner ring turning processing device, including: a turning processing device; said bearing inner ring turning processing device also includes: an inner hole clamping device, and a position adjusting and stabilizing device for the front end of the bearing inner ring.

[0027] The inner hole clamping device includes: a fixed seat 27 with an axial through hole 4, an electric three-jaw chuck 28 with a middle hole (not shown in the drawings) and the rear end is screwed to the fixed seat 27 , The claw feet 29 of the electric three-jaw chuck 28 are provided with a reference retaining surface 1 .

[0028] The position adjusting and stabilizing device for the front end of the inner ring of the bearing comprises: a pull rod 31 provided with a threaded section 30 at the front end and pierced in the axial through hole 4 and the middle hole, an end stop ring pressure plate 12 and a pressure plate sleeved outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com