Green brick tea conveying and cutting device and method

A cutting device and the technology of green brick tea, applied in the field of green brick tea, can solve the problems of large cutting size deviation, a large amount of tea waste, safety accident brick tea, etc., and achieve the effects of avoiding deviation, improving feeding efficiency, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

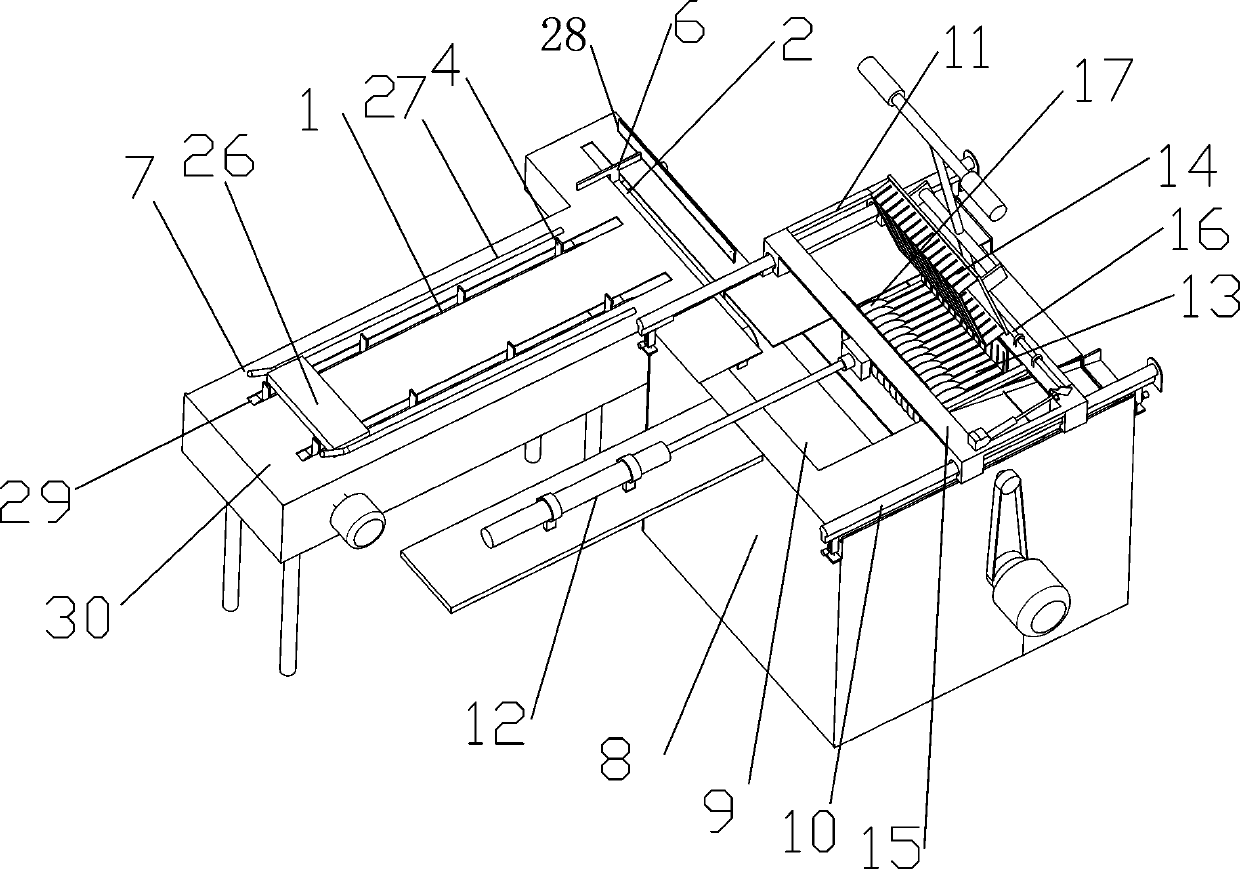

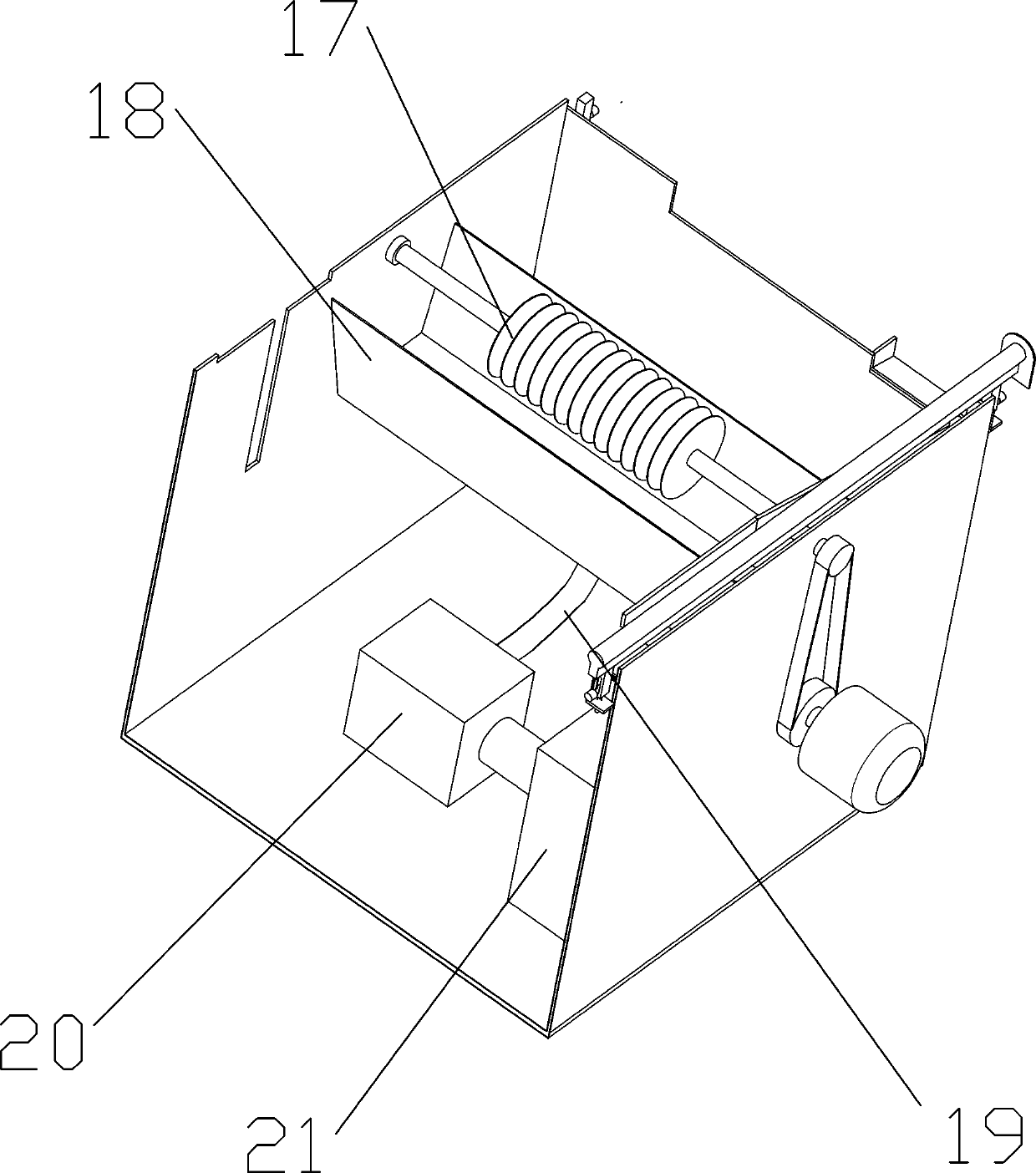

[0041] A blue brick tea conveying and cutting device includes an automatic conveying mechanism and an automatic cutting mechanism.

[0042] Such as Figure 1-2 As shown, specifically, the automatic conveying mechanism is composed of two parts, including a first conveyor belt 1 and a second conveyor belt 2. The first conveyor belt 1 and the second conveyor belt 2 are jointly installed in the first housing 7.

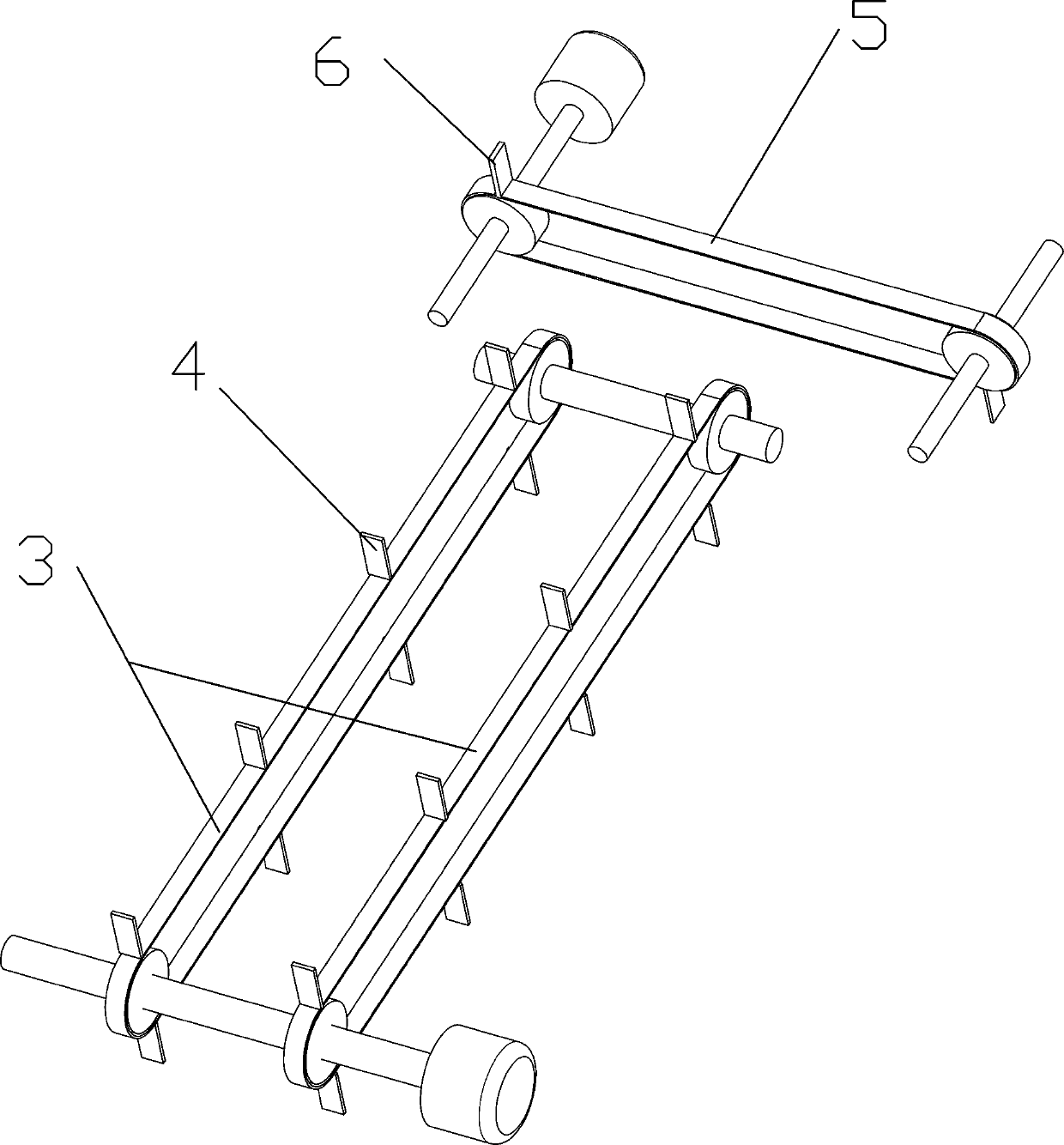

[0043] Such as figure 2 As shown, the first conveyor belt 1 includes a first chain transmission mechanism 3 arranged in pairs. The first chain transmission mechanism 3 includes a transmission chain, a driving wheel, a driven wheel, and a driving shaft, a driven shaft, a driving shaft, and a driven shaft. It is mounted on the first housing 7 through a bearing and driven by the first motor to rotate. A plurality of first push plates 4 are evenly distributed on the chain links of the first chain transmission mechanism 3, and the upper end of the first push plate 4 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com