3D printing mechanism

A 3D printing, stage technology, applied in 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of immature and feasible technology, double the cost, increase the number of motors, etc., to meet the needs of large-scale high-precision Printing requirements, without sacrificing printing accuracy, the effect of increasing the printing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

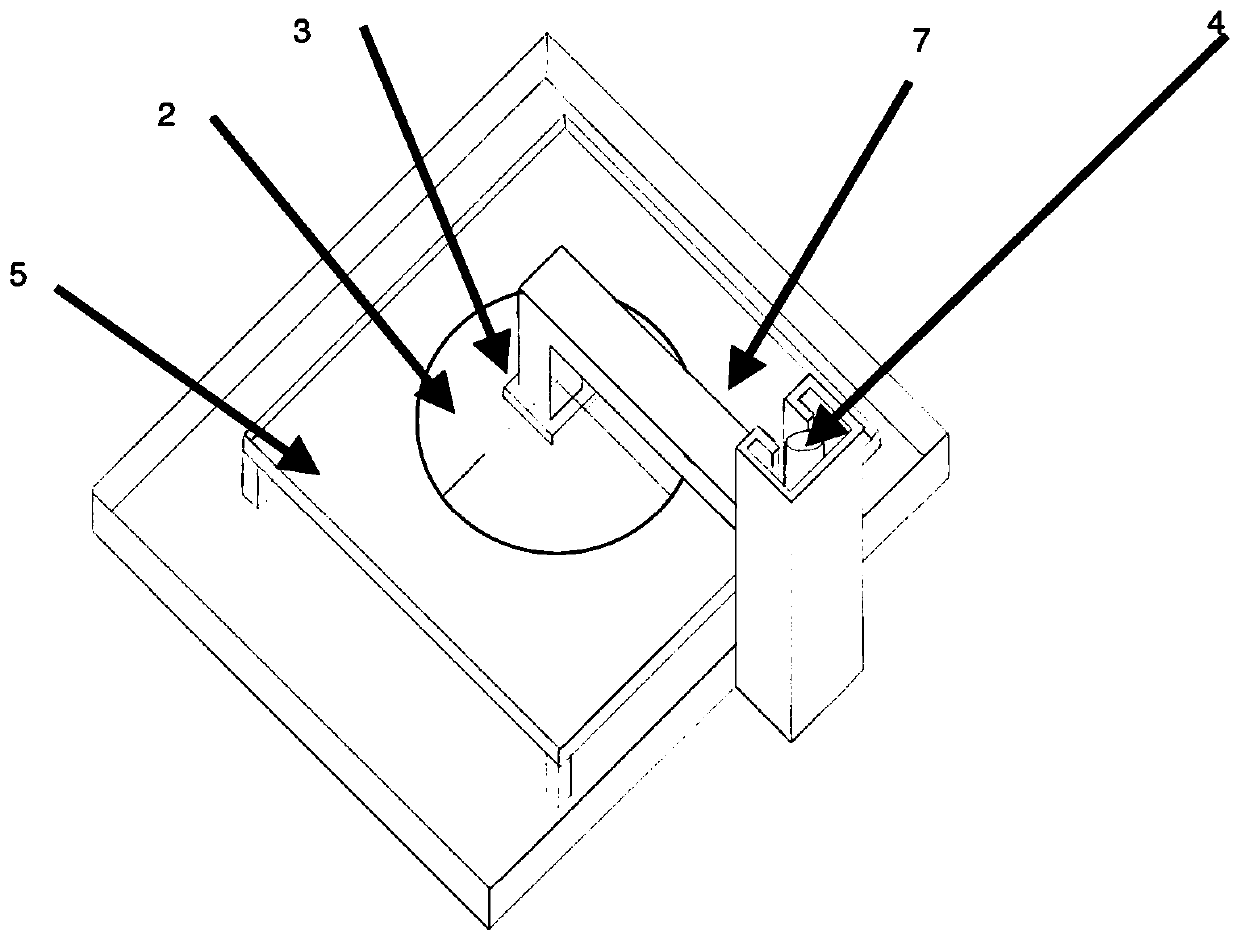

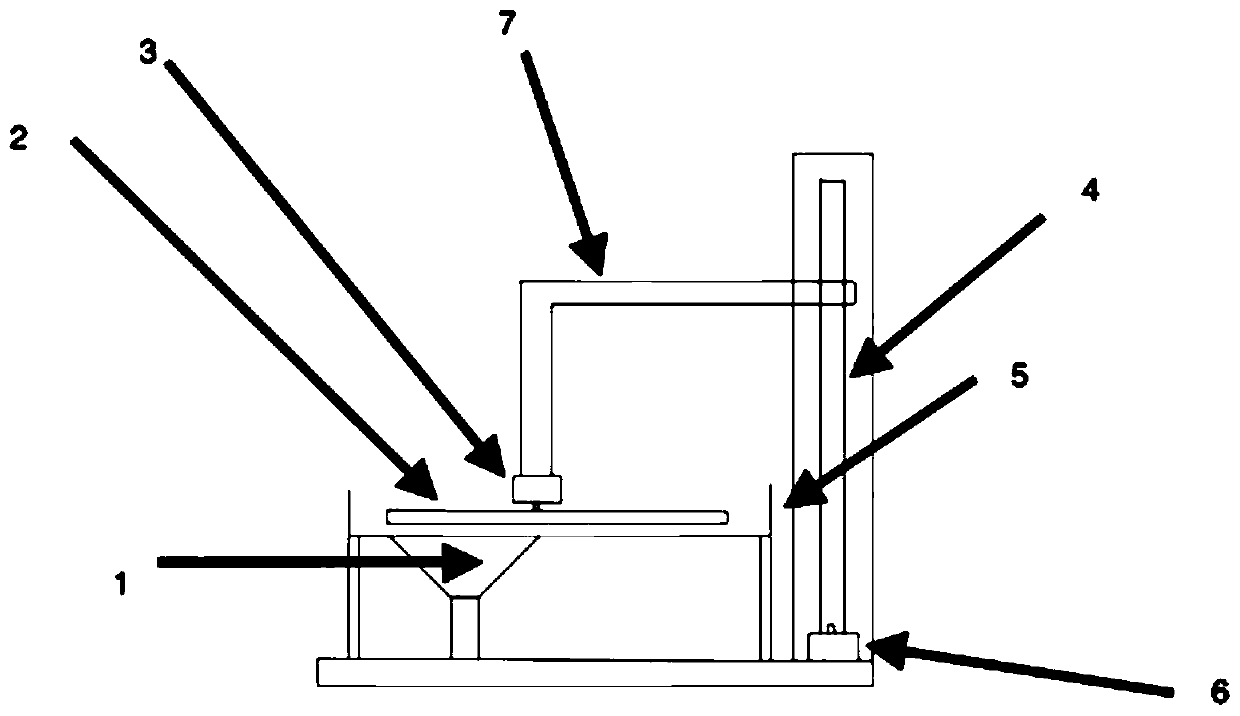

[0025] Such as Figure 1-2 As shown, a 3D printing mechanism includes a printing part and a lifting part;

[0026] The printing part includes a circular stage 2, a first motor 3, a digital light processing projector 1, and a resin tank 5;

[0027] The stage is connected to the motor of the stage, and the motor of the stage drives the stage to rotate when it works;

[0028] A projection plane projected by the digital light processing projector passes through the resin tank and is printed on at least part of the stage;

[0029] The lifting part includes a second motor, a load-bearing shaft of the object stage, a screw rod 4 threadedly connected with the load-bearing shaft, and a limit plate. The second motor drives the screw rod to rotate, and then drives the load-bearing shaft of the object stage to move along the length direction of the screw rod , so that the stage moves along the length of the screw rod.

[0030] The working process of the present invention: the projectio...

Embodiment 2

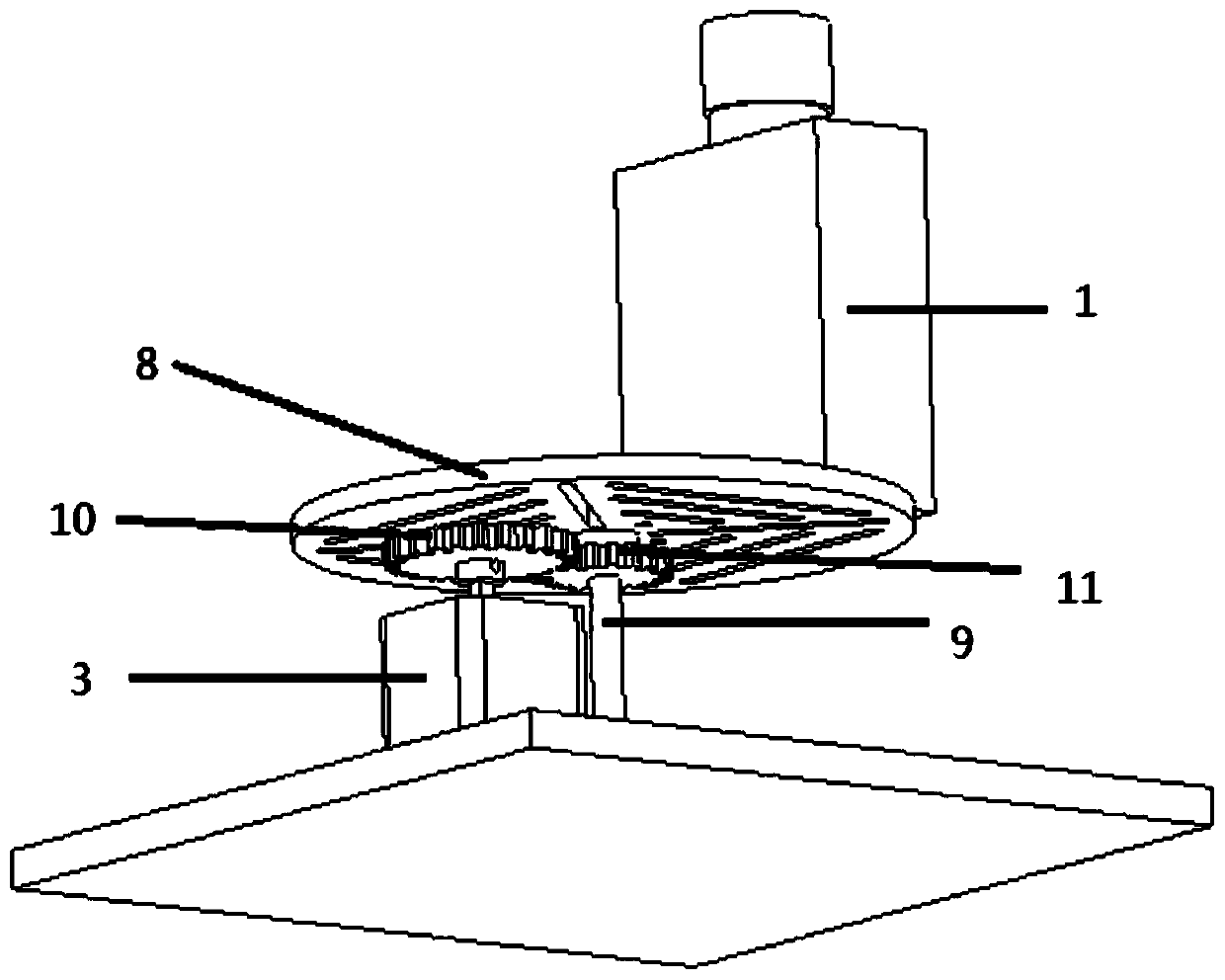

[0032] Such as Figure 3-4 As shown, the first motor can be changed to drive the rotation of the projector, thereby increasing the printing area, specifically: a 3D printing mechanism, including a printing part and a lifting part; the printing part includes a fixed plate 8, a support rod 9. The fixed plate is installed on the support rod and can rotate relative to the support rod; the projector is installed on the fixed plate; the output shaft of the first motor is installed with the first gear 10, and the connection between the fixed plate and the support rod is installed with the first The second gear 11, the second gear is relatively fixed to the fixed plate, the first gear meshes with the second gear; the first motor drives the fixed plate to rotate and further drives the projector to rotate. The fixed plate is provided with several hollow structures to facilitate the fixing of the projector.

[0033] Other structural components and connections of this embodiment are the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com