Cylinder head stamping mark pressing tool and method

A cylinder head and steel stamping technology, applied in stamping, printing, etc., can solve problems such as poor knocking quality, uneven depth of steel stamp marks, skewed fonts, etc., to achieve the effect of improving efficiency and quality, improving appearance quality, and meeting forming requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

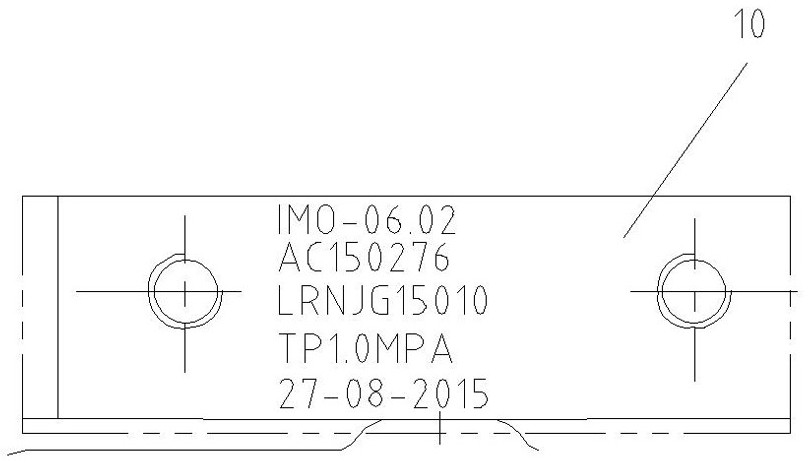

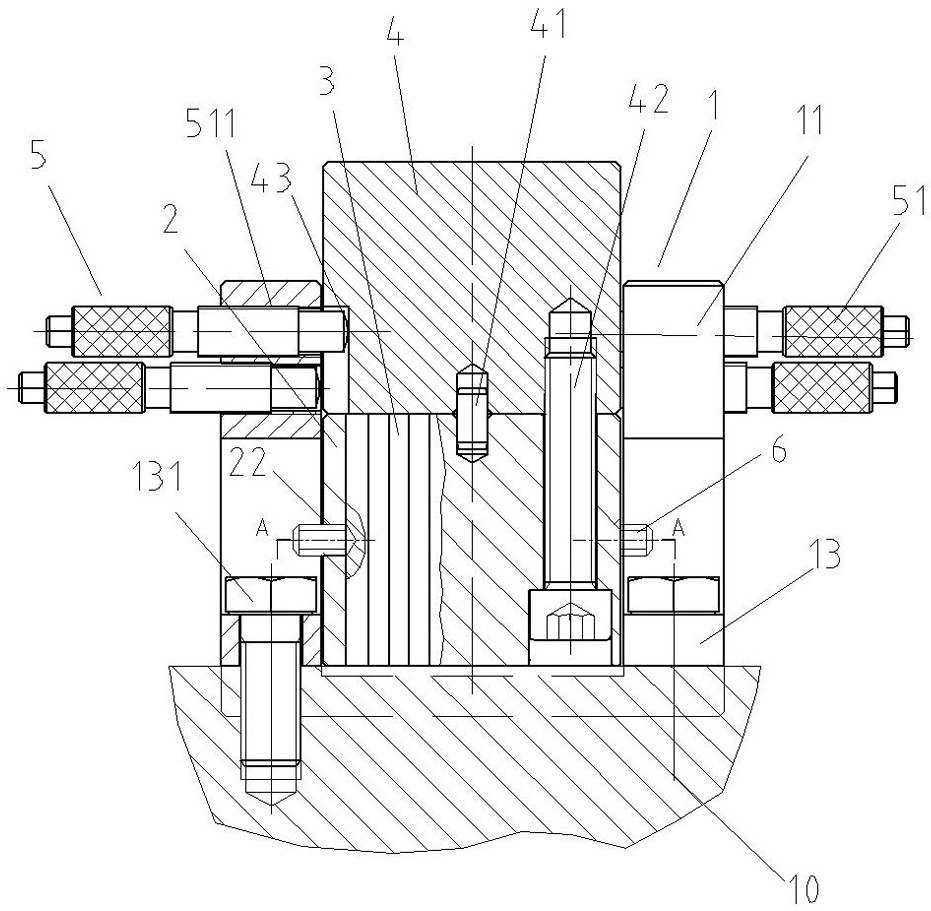

[0034] The present invention will be further described below in conjunction with the accompanying drawings and the embossed embodiment of stamping on the L23 type marine diesel engine cylinder head.

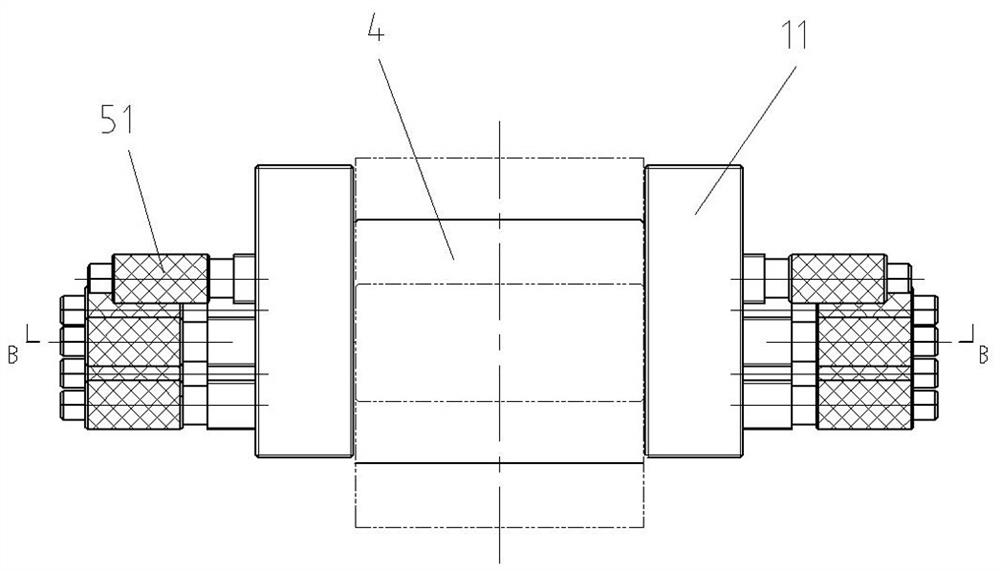

[0035] Such as Figure 2 ~ Figure 6 As shown, this embodiment includes a positioning bracket 1, a stamped font support block 2, a plurality of stamped fonts 3, a pressing block 4 and a stamped font line spacing adjustment mechanism 5, and the positioning bracket 1 is in the shape of a groove with an opening facing the front side, including two sides. Vertical side panels 11 and bottom horizontal panels 12, such as Figure 4 As shown, there is a gap at the bottom of the vertical side plate 11, and the bottom side of the gap is a connecting plate 13, and the connecting plates 13 on both sides of the bottom of the positioning bracket 1 are respectively fixed on both sides of the steel stamp mark of the cylinder head 10 by screws 131.

[0036] Such as Figure 5As shown, the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com