Environment-friendly anti-fouling self-repairing gel coating and synthesis method and application thereof

An environmentally friendly, self-healing technology, used in antifouling/underwater coatings, coatings, and biocide-containing paints, etc., can solve the problem of micropores in the coating, and achieve high inhibition efficiency, fast and long-term inhibition. The effect of biological growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

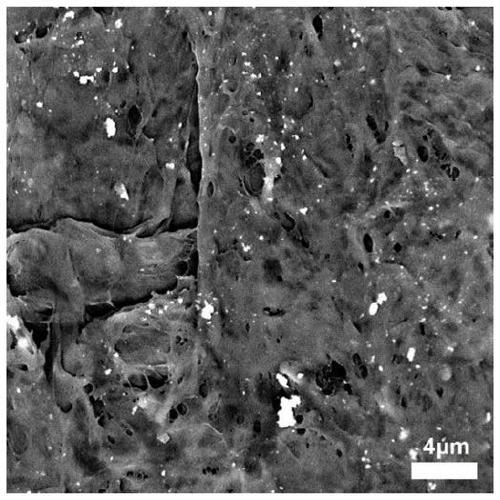

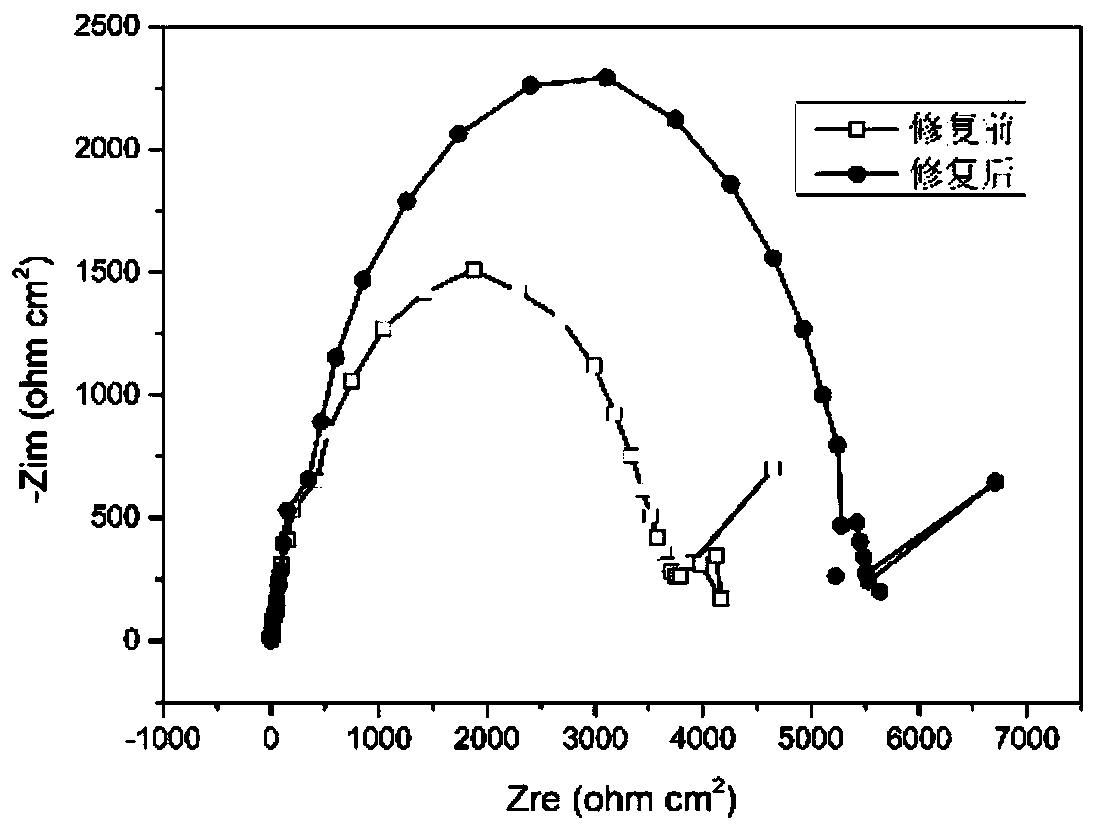

Image

Examples

Embodiment 1

[0069] An environmentally friendly anti-fouling self-repairing gel paint of the present invention is synthesized from component A, component B and component C;

[0070] Specific steps are as follows:

[0071] (1) Synthesis of component A

[0072] Mix 1 g of basic copper sulfate and 60 g of deionized water. Prepare a 1M NaOH aqueous solution, drop it into the basic copper sulfate solution at a rate of 40 drops / min, and form a blue precipitate.

[0073] Use centrifugation (5000rpm, 4min), wash twice to obtain a blue precipitate, then add deionized water to disperse the blue precipitate, and centrifuge again (6000rpm, 4min), wash twice to obtain a blue precipitate.

[0074] Redisperse in 100 mL deionized water. Add 5 mg of butylated hydroxyanisole and 10 mg of dibutyl hydroxytoluene respectively, and react for 4 hours. Centrifuge (6000rpm, 8min), wash with deionized water twice, and freeze-dry for 20h to prepare the final copper salt nanoparticles.

[0075] (2) Synthesis of ...

Embodiment 2

[0082] An environmentally friendly anti-fouling self-repairing gel paint of the present invention is synthesized from component A, component B and component C;

[0083] Specific steps are as follows:

[0084] (1) Synthesis of component A

[0085] Mix 0.8 g of copper nitrate, 0.2 g of copper sulfate, and 100 g of deionized water. Prepare a 1M NaOH aqueous solution, drop it into the copper solution at a rate of 60 drops / min, and form a blue precipitate.

[0086] Use centrifugation (4000rpm, 5min), wash 3 times to obtain a blue precipitate, then add deionized water to disperse the blue precipitate, and centrifuge again (8000rpm, 5min), wash 3 times to obtain a blue precipitate.

[0087] Redisperse in 100 mL deionized water. Add 10 mg of tocopherol and 3 mg of tea polyphenols respectively, and react for 2 hours. The final copper salt nanoparticles were prepared by centrifugation (8000 rpm, 5 min), washing with deionized water for 3 times, and freeze-drying for 24 h.

[0088] ...

Embodiment 3

[0095] An environmentally friendly anti-fouling self-repairing gel paint of the present invention is synthesized from component A, component B and component C;

[0096] Specific steps are as follows:

[0097] (1) Synthesis of component A

[0098] Mix 0.5 g of copper chloride, 0.5 g of copper carbonate, and 50 g of deionized water. Prepare a 1M NaOH aqueous solution, drop it into the copper solution at a rate of 50 drops / min, and form a blue precipitate.

[0099] Use centrifugation (8000rpm, 10min), wash 3 times to obtain a blue precipitate, then add deionized water to disperse the blue precipitate, and centrifuge again (4000rpm, 10min), wash 3 times to obtain a blue precipitate.

[0100] Redisperse in 80 mL deionized water. Add 7 mg of flavonoids and 3 mg of tert-butylhydroquinone respectively, and react for 1 h. The final copper salt nanoparticles were prepared by centrifugation (4000 rpm, 10 min), washing with deionized water three times, and freeze-drying for 22 h.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com