Method for indirect dispersion strengthening of platinum channel

A platinum channel and dispersion strengthening technology, which is applied in metal material coating process, fusion spraying, coating, etc., can solve the problem of platinum volatilization, high temperature strength and high temperature creep performance degradation, and can not meet the requirements of TFT-LCD liquid crystal glass substrate. To meet the environmental requirements and other issues, to avoid zirconium, improve high temperature strength and creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

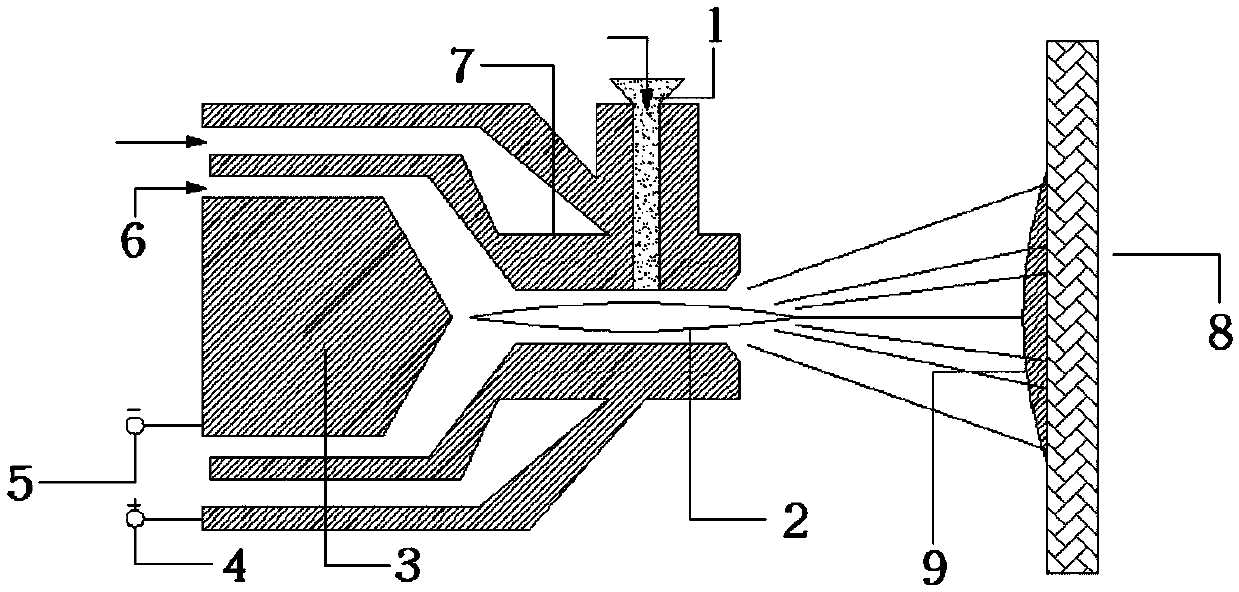

[0010] like figure 1 , the zirconia lattice type used is yttrium-stabilized zirconia, the yttrium-stabilized zirconia powder is put into the plasma spraying equipment through the powder inlet 1, the cathode 3 and the anode 7 are respectively connected to the power supply negative pole 5 and the power supply positive pole 4, and the DC power supply positive pole 4 1. A potential difference is generated between the anode 7 and the cathode 3 under the action of the negative electrode 5 of the DC power supply, and the yttrium-stabilized zirconia powder is fused to form the plasma flame 2 through the high-frequency spark ignition arc, and the plasma flame 2 is transported through the cooling medium plasma gas 6, It is sprayed on the outer wall of the platinum channel body 8 to form a dense and uniform yttrium-stabilized zirconia coating 9 with a thickness of 0.10-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com