Arc fuse preparation method of ODS steel

A technology of ODS and fuse, applied in the field of high-temperature alloys, can solve the problems of difficulty in meeting the huge demand for structural materials, low manufacturing efficiency, complex process, etc., and achieve the effect of low cost, high production efficiency and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

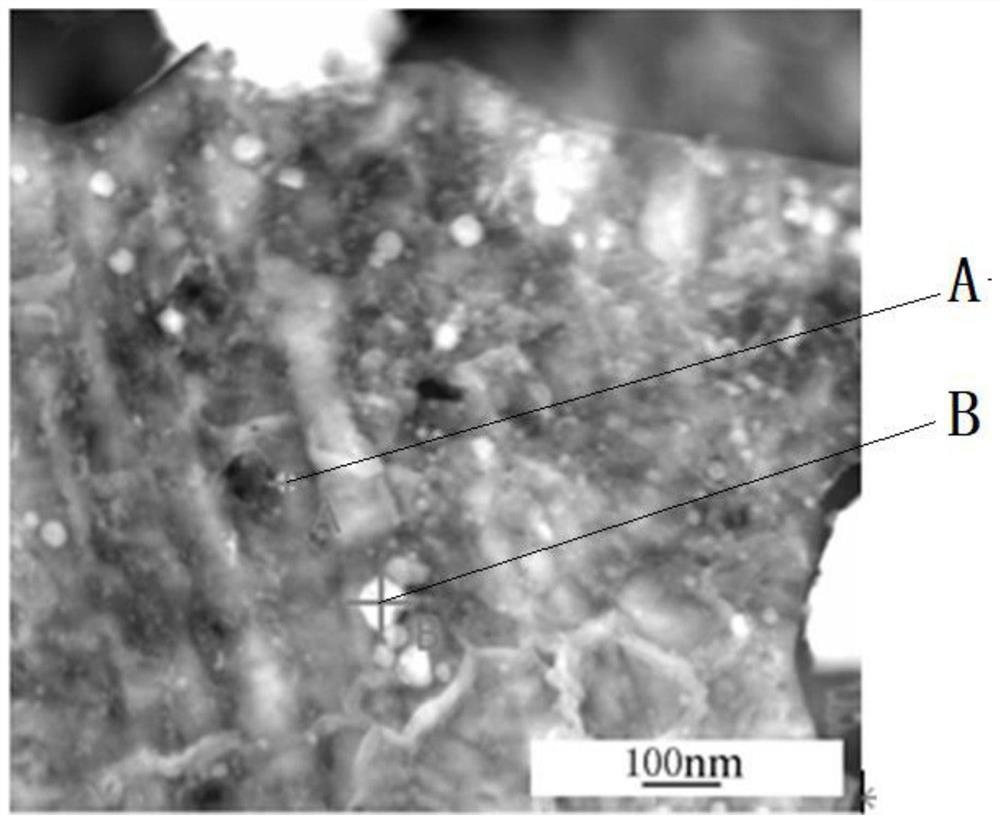

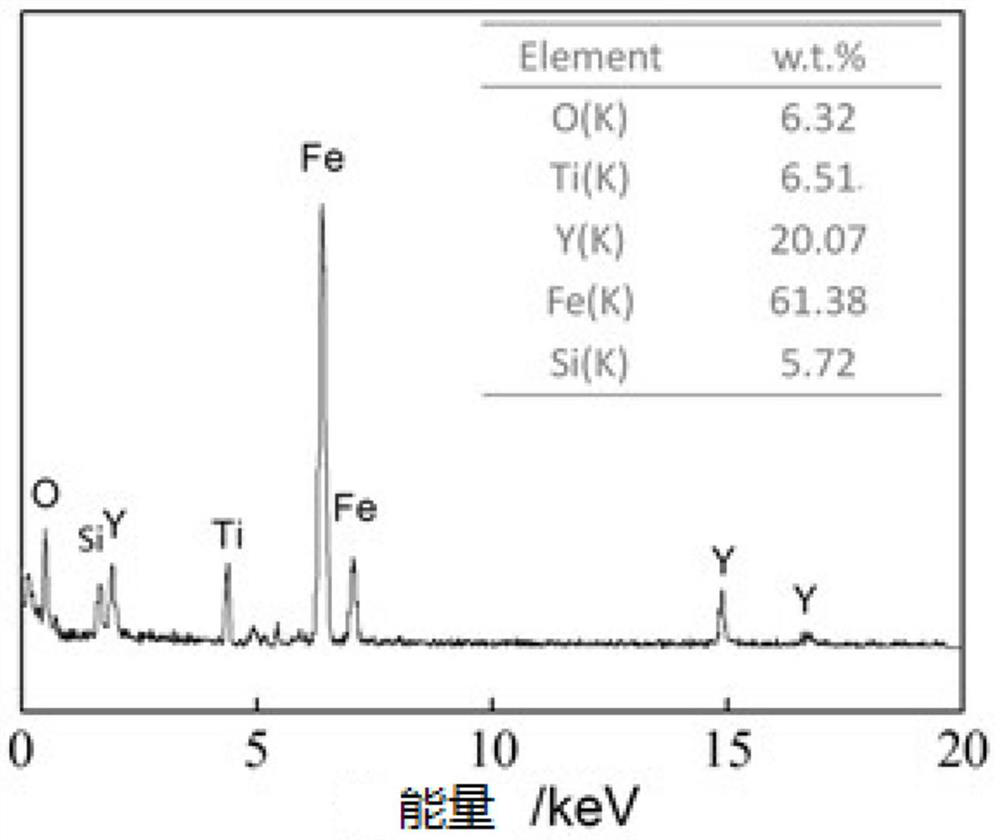

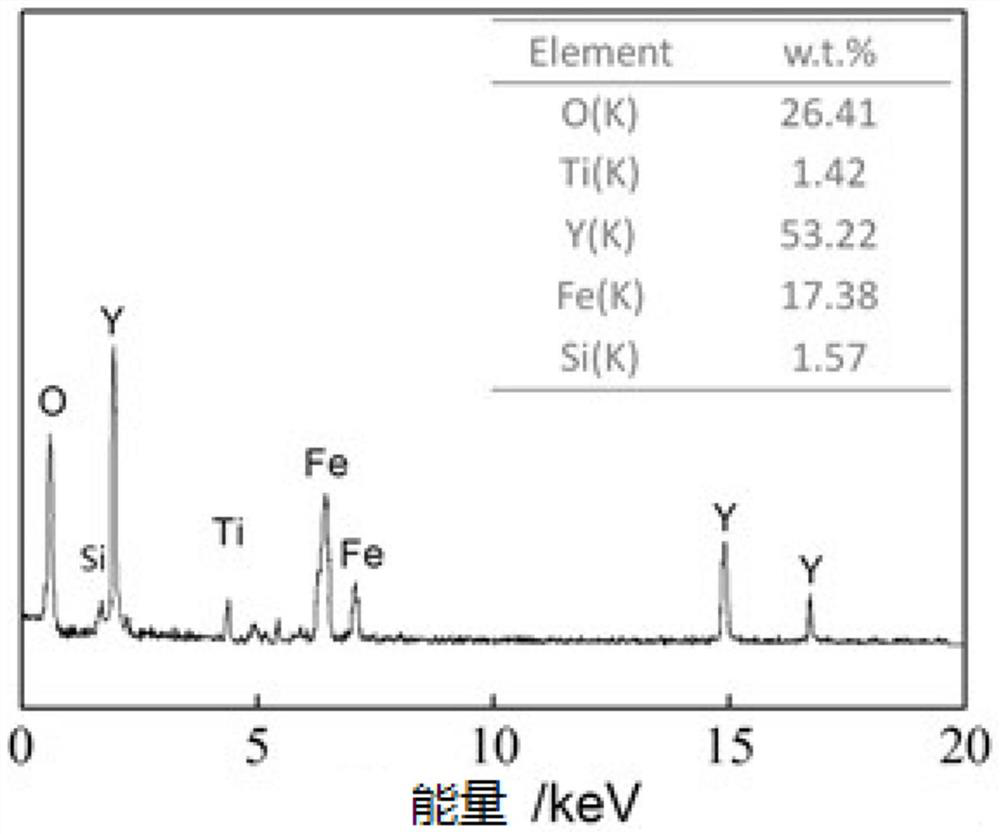

Image

Examples

Embodiment 1

[0026] (1) Fe, Cr, Ti, Si and Y 2 o 3 Powder according to mass fraction, 90.7% Fe, 9% Cr, 0.1% Ti, 0.1% Si, 0.1% Y 2 o 3 It is configured into a mixed powder, and then placed in a planetary ball mill for mechanical alloying, the ball milling time is 10 hours, the ball-to-material ratio is 7:1, the ball milling speed is 200rpm, and high-purity argon is used for protection during the ball milling process;

[0027] (2) the alloy powder prepared by above-mentioned mechanical alloying and B 2 o 3 , ZrSiO 4 and TiO 2 Mix evenly on a planetary ball mill, add B 2 o 3 , ZrSiO 4 and TiO 2 The mass percentages of the alloy powder are: 0.1% B 2 o 3 , 0.5% ZrSiO 4 , 0.2%TiO 2 ; The ball milling time is 0.5h, the ball-to-material ratio is 5:1, the ball milling speed is 50rpm, and the ball milling medium is absolute ethanol.

[0028] (3) Dry the powder after ball milling in a vacuum drying oven at a temperature of 60°C for 0.5h and a vacuum degree of not higher than 1Pa;

[00...

Embodiment 2

[0033] (1) Fe, Cr, W, Ti, Si and Y2O3 powders are calculated according to mass fraction, 63.6% Fe, 25% Cr, 5.0% W, 0.4% Ti, 5.0% Si, 1.0% Y 2 o 3 It is configured into a mixed powder, and then placed in a planetary ball mill for mechanical alloying, the ball milling time is 100h, the ball-to-material ratio is 30:1, the ball milling speed is 500rpm, and high-purity argon is used for protection during the ball milling process;

[0034] (2) the alloy powder prepared by above-mentioned mechanical alloying and B 2 o 3 , ZrSiO 4 and TiO 2 Mix well on a planetary ball mill. Joined B 2 o 3 , ZrSiO 4 and TiO 2 The mass percentages of the alloy powder are: 0.5% B 2 o 3 , 1.0% ZrSiO 4 , 1.0%TiO 2 ; The ball milling time is 10h, the ball-to-material ratio is 10:1, the ball milling speed is 300rpm, and the ball milling medium is absolute ethanol;

[0035] (3) Dry the powder after ball milling in a vacuum drying oven at a temperature of 120°C for 10 hours and a vacuum degree of...

Embodiment 3

[0040] (1) Fe, Cr, W, Ti, Si and Y2O3 powders are calculated according to mass fraction, 75.7% Fe, 18% Cr, 2.0% W, 1.0% Ti, 3.0% Si, 0.3% Y 2 o 3 It is configured into a mixed powder, and then placed in a planetary ball mill for mechanical alloying, the ball milling time is 100h, the ball-to-material ratio is 20:1, the ball milling speed is 300rpm, and high-purity argon is used for protection during the ball milling process;

[0041] (2) Alloy powder B prepared by above-mentioned mechanical alloying 2 o 3 , ZrSiO 4 and TiO 2 Mix evenly on a planetary ball mill, add B 2 o 3 , ZrSiO 4 and TiO 2 The mass percentages of the alloy powder are: 0.7% B 2 o 3 , 0.8% ZrSiO 4 , 1.0%TiO 2 ; The ball milling time is 2h, the ball-to-material ratio is 7:1, the ball milling speed is 200rpm, and the ball milling medium is absolute ethanol;

[0042] (3) Dry the powder after ball milling in a vacuum drying oven at a temperature of 90°C for 3 hours and a vacuum degree of not higher th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com