Steel plate supporting bracket

A technology for supporting brackets and steel plates, which is applied to the on-site preparation and construction of pillars and building components. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

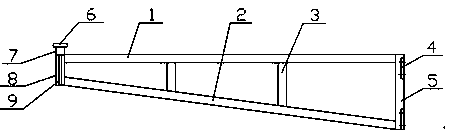

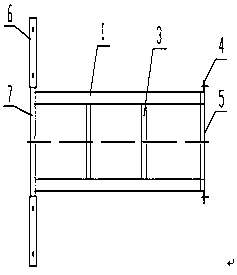

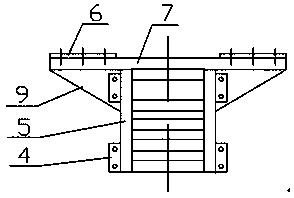

[0010] Refer to the attached figure 1 , attached figure 2 And attached image 3 A steel plate supporting bracket of the present invention will be described in detail below.

[0011] A steel plate supporting bracket of the present invention, its structure includes an upper jacking rod 1, a lower jacking rod 2, a front jacking rod 8 and a rear jacking rod 5, and the upper jacking rod 1 and the lower jacking rod 2 are two, the front jacking rod 8 and the rear jacking rod 5 are respectively arranged on the left end and the right end of the upper jacking rod 1 and the lower jacking rod 2, and the two sides of the rear jacking rod 5 are Connecting bolts 4 are provided respectively, a support sleeve 7 is provided on the upper part of the front jacking rod 8 , and rolling rods 6 are respectively provided on both sides of the support sleeve 7 .

[0012] The present invention can be manufactured by referring to the drawings for those skilled in the art.

[0013] Finally, it should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com