Cover structure of clothes washing machine

A washing machine and machine cover technology, applied in the field of washing machines, can solve the problems of large friction noise, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

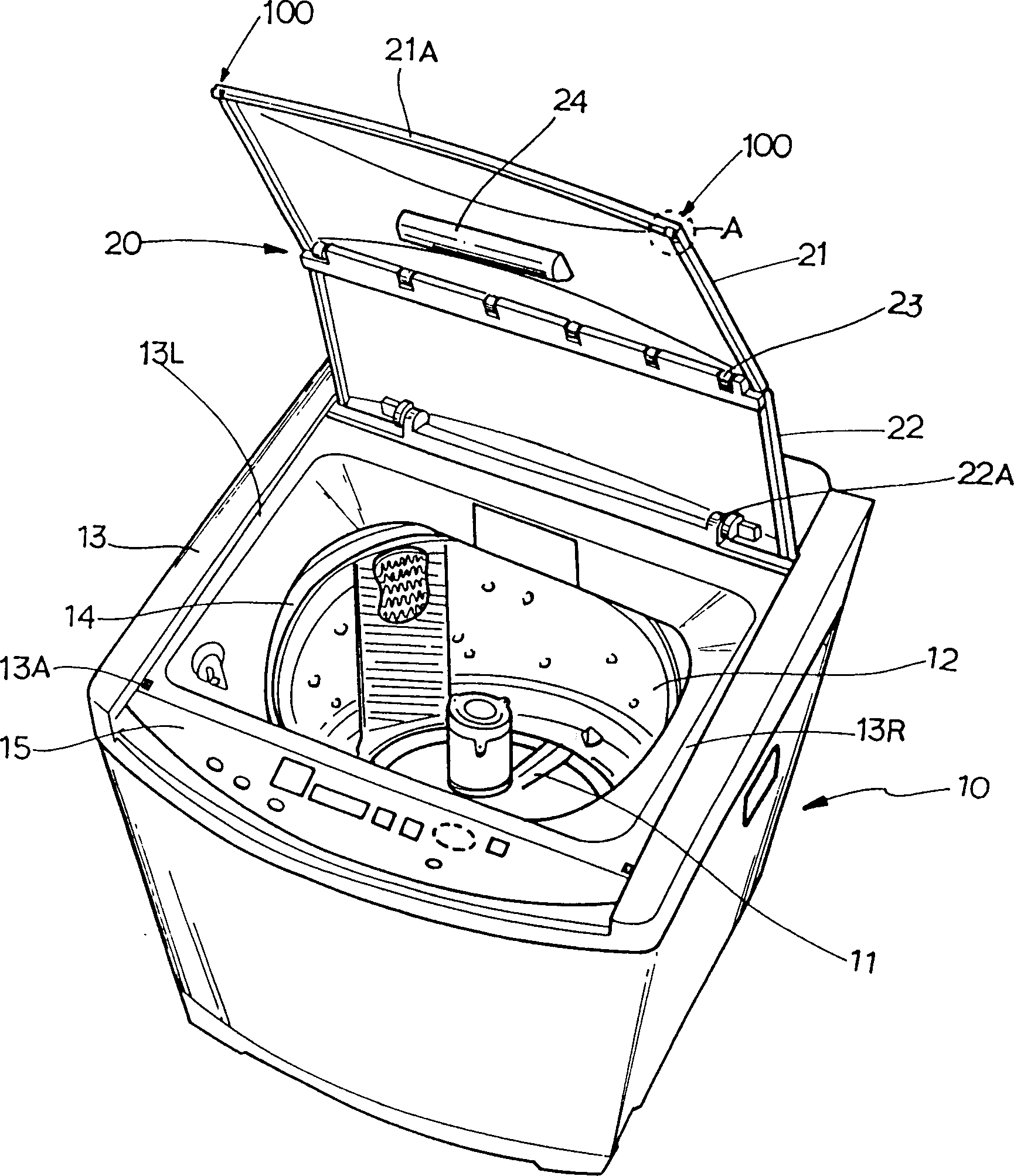

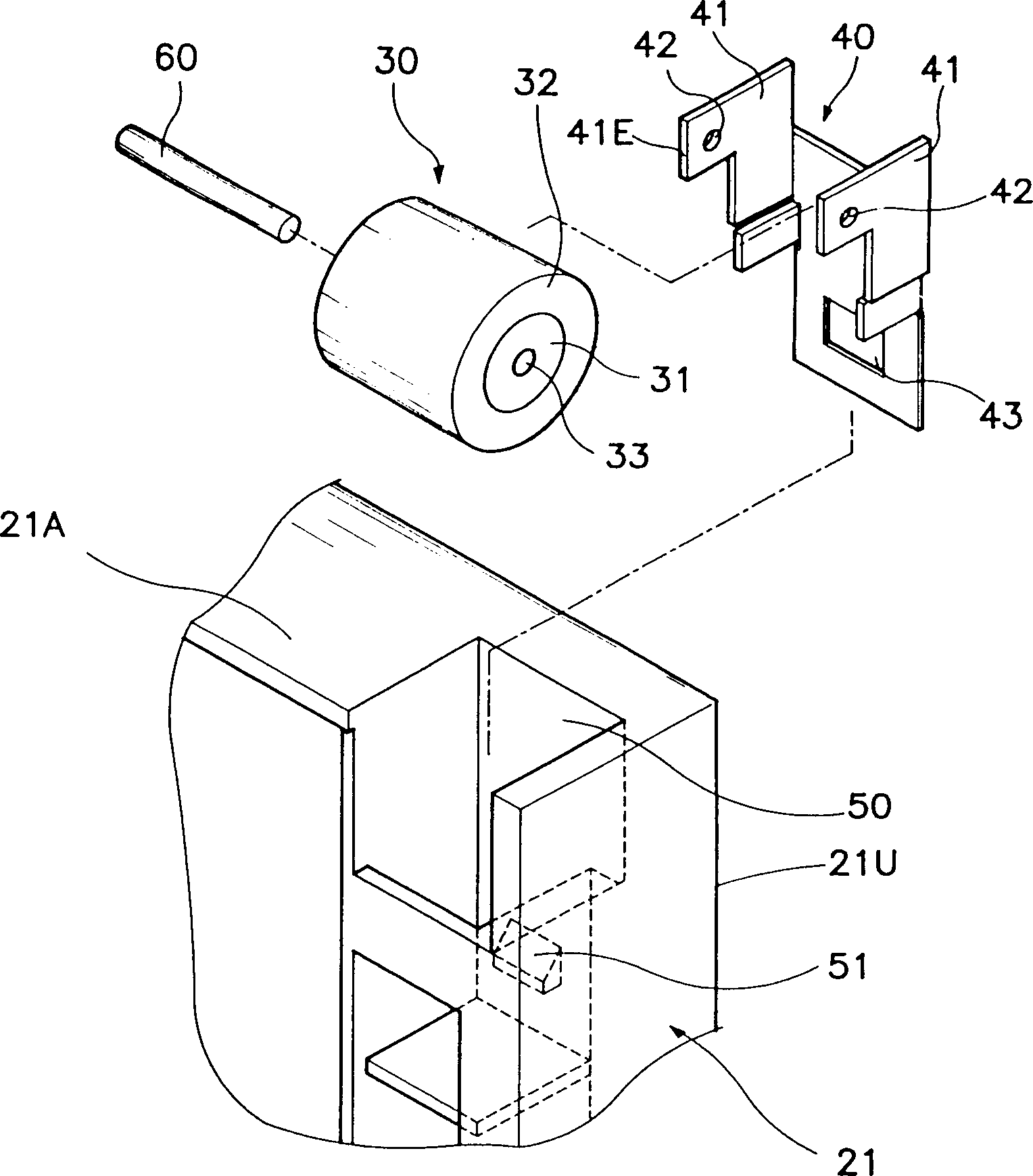

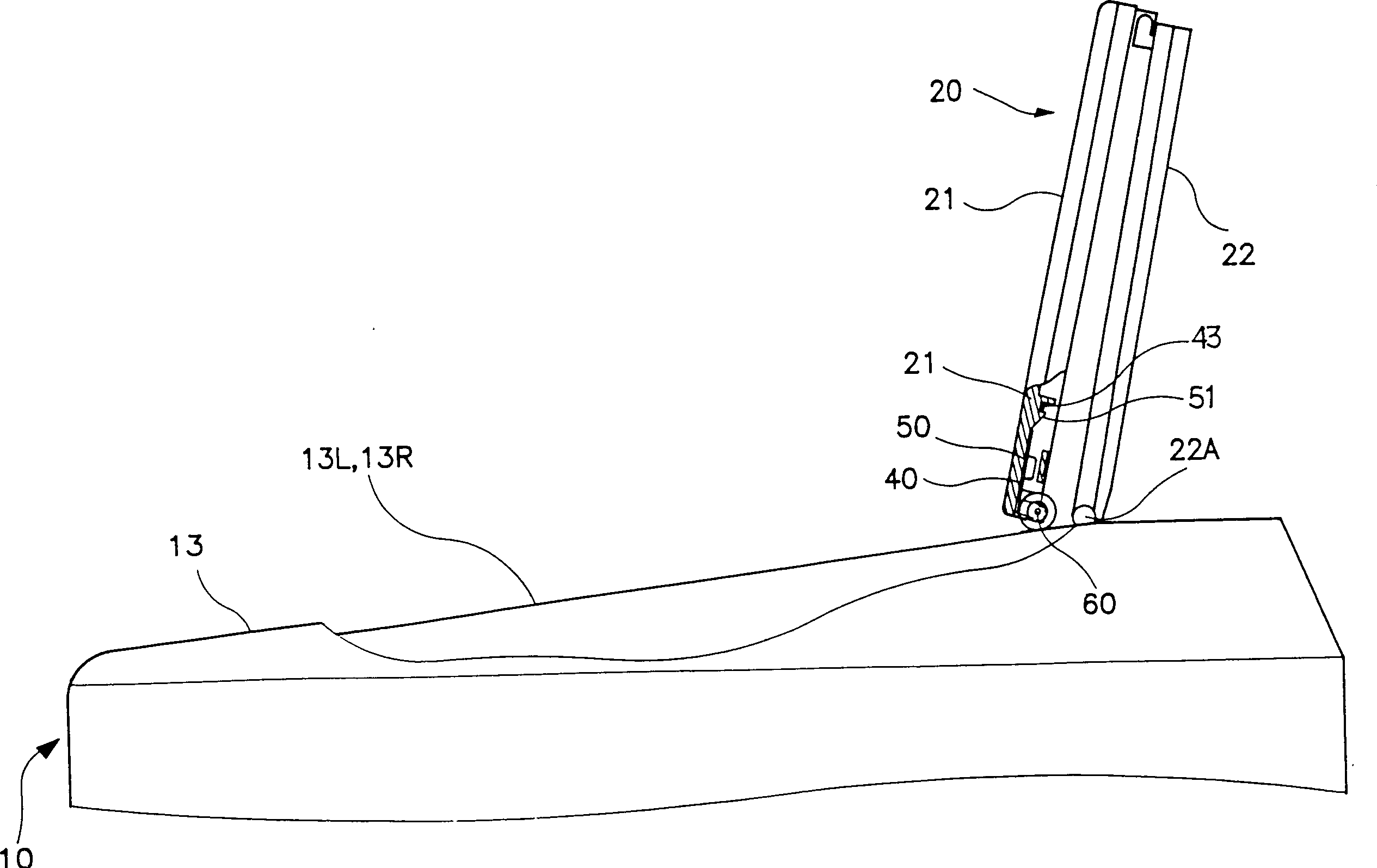

[0017] refer to figure 1 and figure 2 , the first plate 21 shown in the figure, its front end 21A cooperates with the upper surface of the cover frame 13, and has a pair of roller devices 100. Each roller assembly includes: a roller 30, a bracket 40 for mounting the roller. The bracket 40 is inserted into a groove 50 on the front end 21A.

[0018] The roller 30 includes: a wheel frame 31 made of plastic; a roller 32 made of rubber, which is sleeved on the outer surface of the wheel frame 31 . The rubber is used to absorb the vibrations that occur when the washing machine is turned on. There is an axle hole 33 in the center of the wheel frame, which can freely receive the axle 60 .

[0019] The bracket 40 has a pair of support plates 41 for supporting the ends of the roller 30 by means of the shaft 60 which is fixedly mounted in the pair of holes 42 . This hole 42 is located close to the outer edge 41E of the support plate 41 so that the rollers 30 protrude outward to som...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com