Building engineering quality flatness detection device

A technology of construction engineering and detection devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of real-time recording of engineering quality planes, large-scale or small-scale plane detection, and low detection accuracy. , to achieve the effect of flexible design, error avoidance and convenient comparison

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

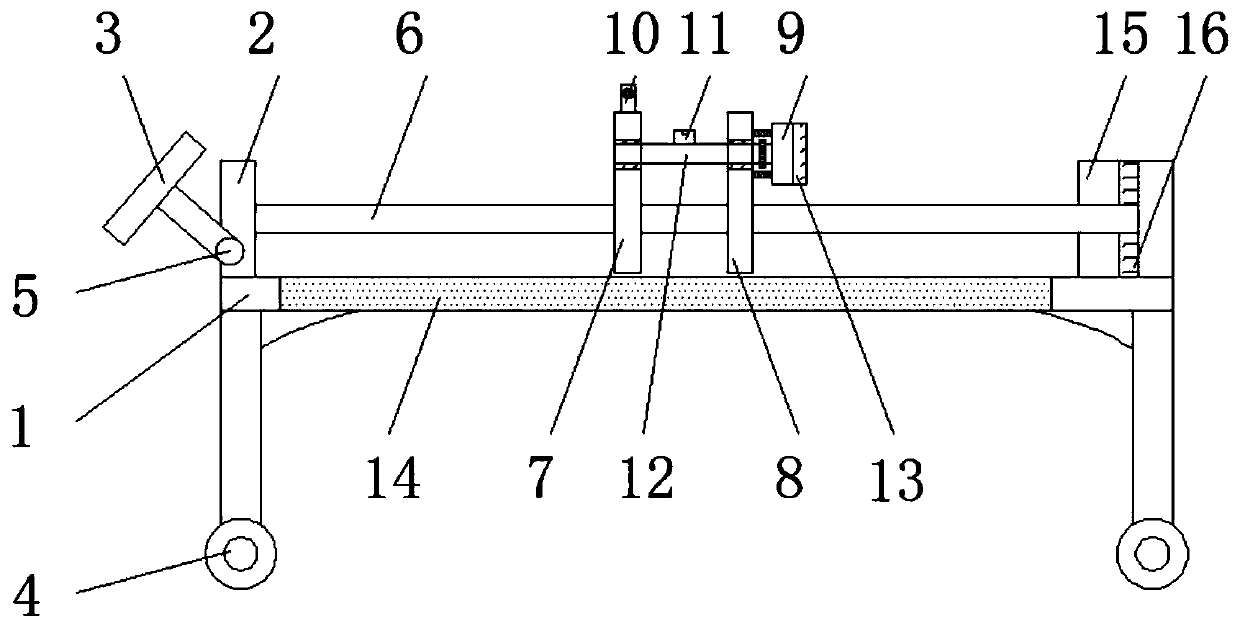

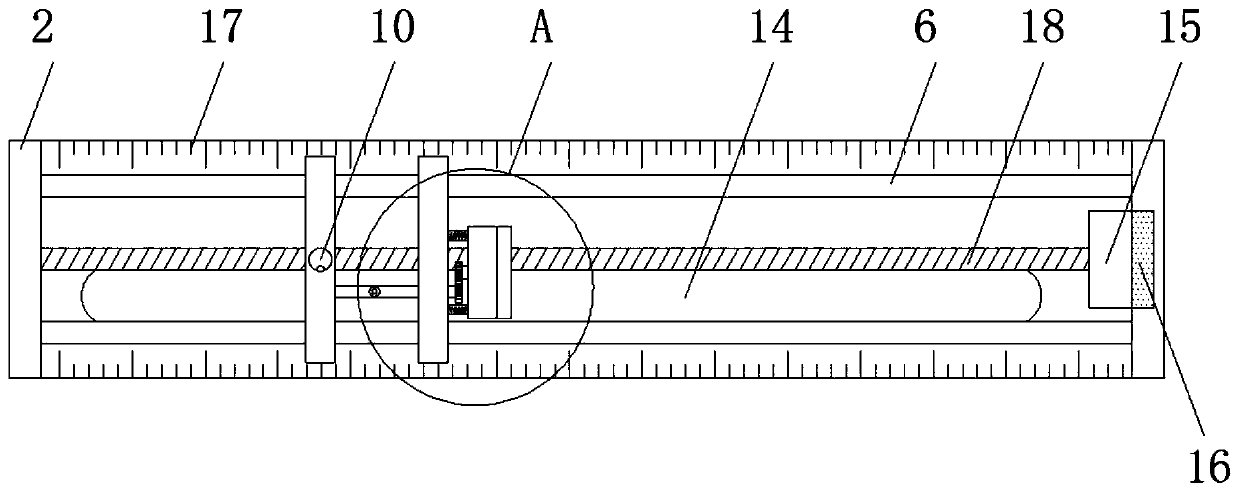

[0028] like Figure 1-5 As shown, a detection device for construction quality flatness, including a platform frame 1 and a guide rail frame 2, the bottom end of the platform frame 1 is equipped with a universal self-locking wheel 4, and the surface of the platform frame 1 is provided with a through groove 14. A control device 3 is installed on one side of the guide rail frame 2, and the control device 3 is rotationally connected with one end of the guide rail frame 2 by setting a damping shaft 5, and a stepping motor 15 and a rotary encoder 16 are installed on the other end of the guide rail frame 2 , the positions between the guide rail frames 2 are respectively movably equipped with screw rods 18 and embedded welded slide rods 6, and two slide rods 6 are respectively located on both sides of the screw rod 18, and the output end of the stepping motor 15 is connected to the wire rod 6. Rod 18 is connected, and the surface movable type of screw mandrel 18 and slide bar 6 is pro...

Embodiment 2

[0033] like Figure 1-5 Shown, a kind of detection device that is used for the flatness of construction engineering quality, on the basis of embodiment 1, rotating bar 12 is arranged on the central axis position between slide bar 6 and screw mandrel 18, and is positioned at slide bar 6 and screw bar The top of the rod 18 and the bottom of the rotating rod 12 correspond to the through groove 14 .

[0034] like Figure 5 As shown, the second gear 22 is welded to the end of the rotating rod 12 extending out of the second movable plate 8, and the output end of the servo motor 9 is connected to the first gear 21, and the first gear 21 and the second gear 22 are meshed with each other, and the transmission connect.

[0035] Through the above technical scheme, the rotating rod 12 is set, and the output end of the servo motor 9 is driven by the first gear 21 and the second gear 22, thereby driving the laser distance measuring device 11 on the rotating rod 12 to rotate, and the angle...

Embodiment 3

[0037] like Figure 1-5 As shown, a detection device for construction quality flatness, on the basis of Embodiment 1, a camera probe 10 is installed on the top of the first movable plate 7, and the control device 3 is electrically connected.

[0038] like figure 2 As shown, the edge of both sides of the platform frame 1 parallel to the slide bar 6 is provided with a scale line 17, which is convenient for real-time observation and detection of the precise range.

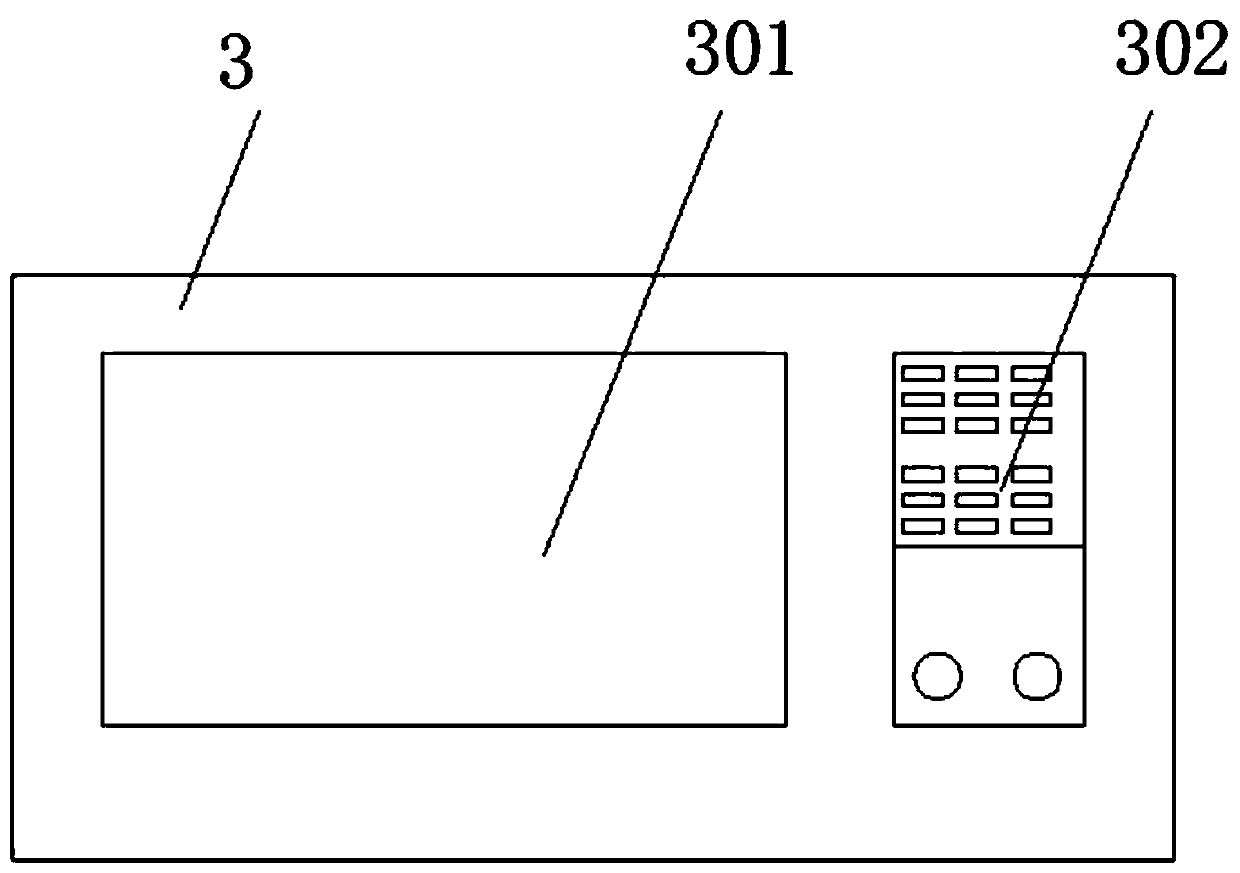

[0039] like image 3As shown, the control device 3 includes a display screen 301, a control button 302 and a built-in data processor, and the control button 302 includes a digital button and a switch.

[0040] Through the above-mentioned technical scheme, the camera probe 10 set, the camera probe 10 works in real time, along with the parallel movement of the movable frame, a whole section of the real scene project is photographed and displayed on the display screen 301, which is convenient for comparison with the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com