A comparison and evaluation method for cigarette sensory quality and application thereof

A sensory quality and evaluation method technology, applied in data processing applications, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A method for determining the amount of lapping glue applied to cigarettes, designing different gradients of the amount of lapping glue applied to cigarettes of the Golden Leaf brand, which are 1.5, 2.0, 2.5, 3.0mL / thousand sticks, and the sample numbers are 0# , 1#, 2#, 3#. Among them, 0# is used as the control sample. Samples were prepared according to the requirements of GB 5606.4-2005 "Sensory Technical Requirements for Cigarettes". Balance the moisture content of the sample according to the method of GB / T 16447-2004 "Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products".

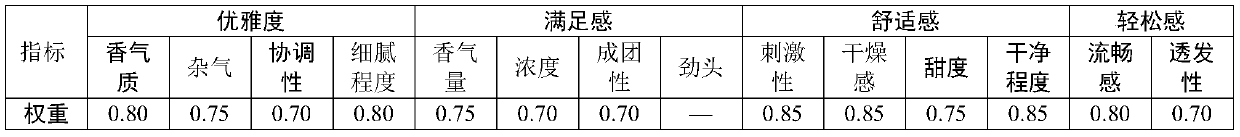

[0078] The evaluation personnel compare and score the samples in Table 3 according to the assignment rules in Table 1, and then make statistics on the sub-items and overall scores of each sample. The results are shown in Table 4. It can be seen from Table 4 that compared with the 0# control sample, the sensory quality of the 1# sample is slightly better on the wh...

Embodiment 2

[0082] A method for determining the filling method of cigarettes. It evaluates the shredded and leaf-filled finished cigarette samples of the second-class cigarettes of the Golden Leaf brand. The sample numbers are 0# and 1#, respectively. Among them, 0# is the leaf feeding sample and serves as the control sample. Samples were prepared according to the requirements of GB5606.4-2005 "Sensory Technical Requirements for Cigarettes". Balance the moisture content of the sample according to the method of GB / T 16447-2004 "Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products".

[0083] The evaluation personnel compare and score the test samples in Table 3 according to the assignment rules in Table 1, and then make statistics on the sub-items and overall scores of each sample. The results are shown in Table 5. As can be seen from Table 5, compared with the control sample, the overall sensory quality of the 1# sample is not significantly worse or better...

Embodiment 3

[0087] A method for determining the drying strength of cigarettes. It evaluates cigarette samples of different drying strengths of the first-class golden leaf brand cigarettes. The drying strength design is shown in Table 6, and the sample numbers are G0, G1, G2, and G3. Among them, G0 was used as the control sample. Samples were prepared according to the requirements of GB5606.4-2005 "Sensory Technical Requirements for Cigarettes". Balance the moisture content of the sample according to the method of GB / T 16447-2004 "Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products".

[0088] Table 6 Design table of parameters for different leaf silk drum drying tests

[0089]

[0090] The evaluation personnel compare and score the test samples in Table 3 according to the assignment rules in Table 1, and then make statistics on the sub-items and overall scores of each sample. The results are shown in Table 7. It can be seen from Table 7 that compared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com