Defect analysis and closed-loop management system for accessory auxiliary equipment of a transformer substation

A technology of auxiliary equipment and defect analysis, applied in information technology support systems, data processing applications, instruments, etc., can solve the problems of lack of technical support means and low operation and maintenance efficiency of auxiliary facilities, achieve reasonable configuration, and improve data collection and storage. Quality, the effect of improving the management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

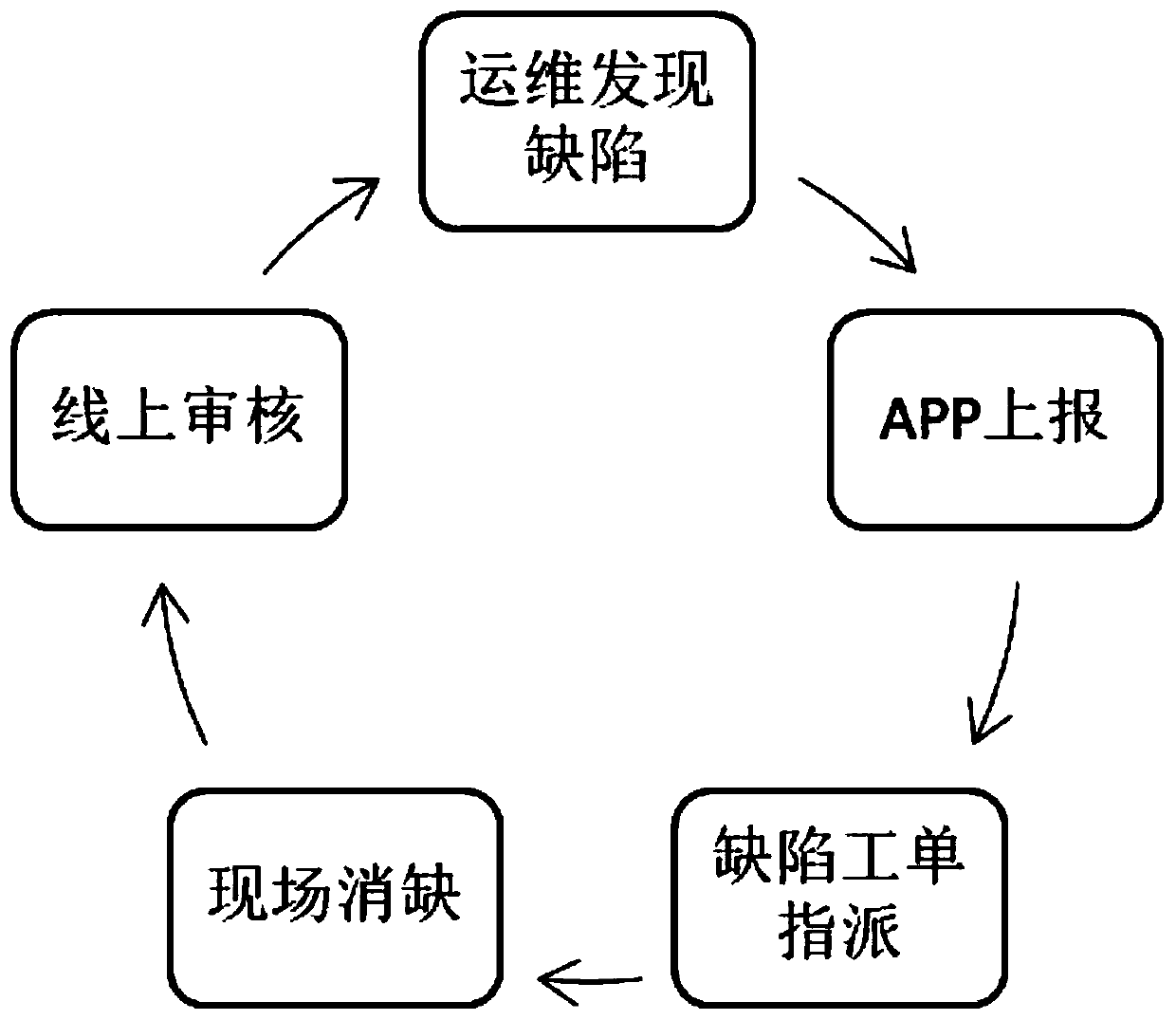

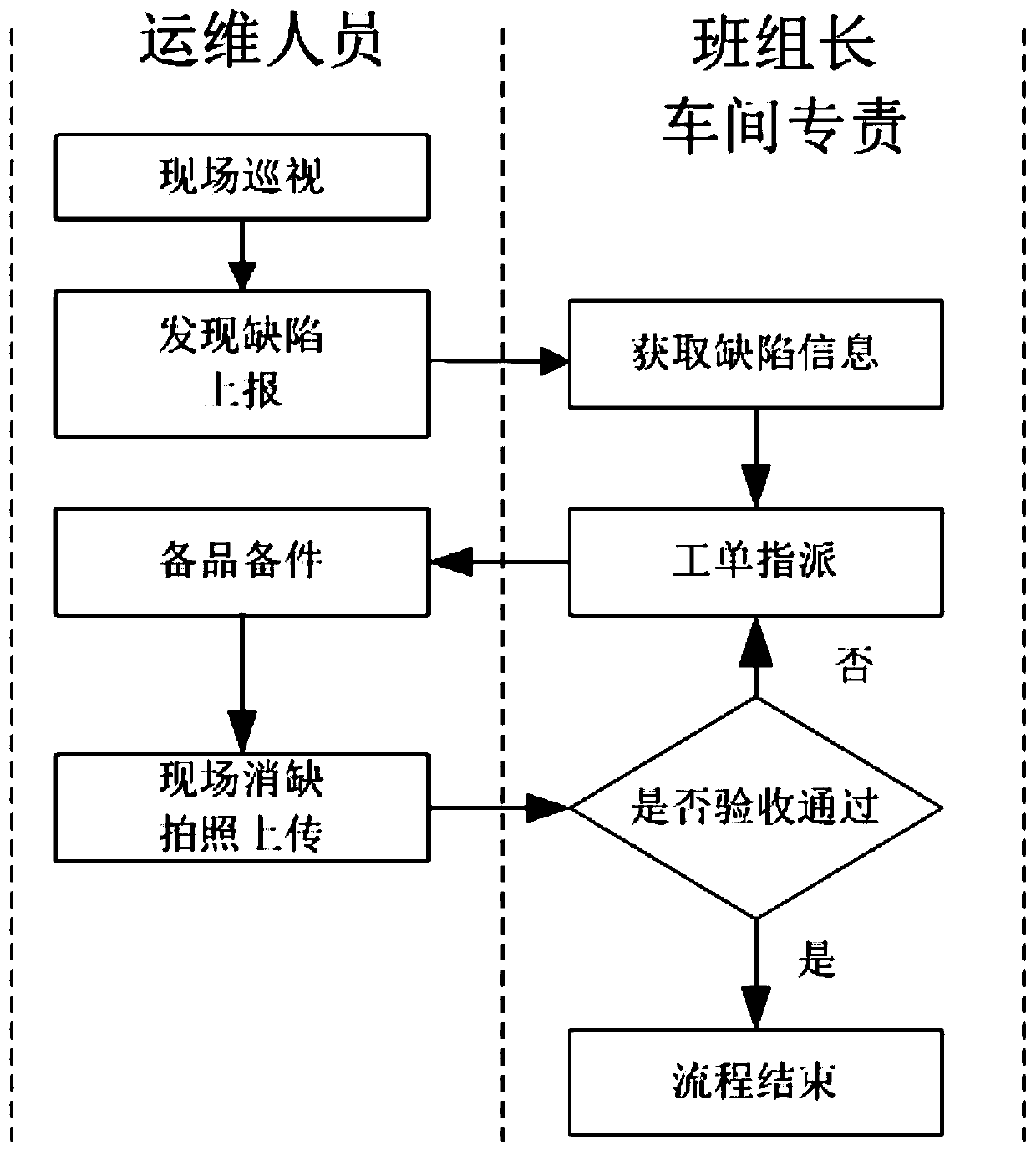

Problems solved by technology

Method used

Image

Examples

Embodiment 1

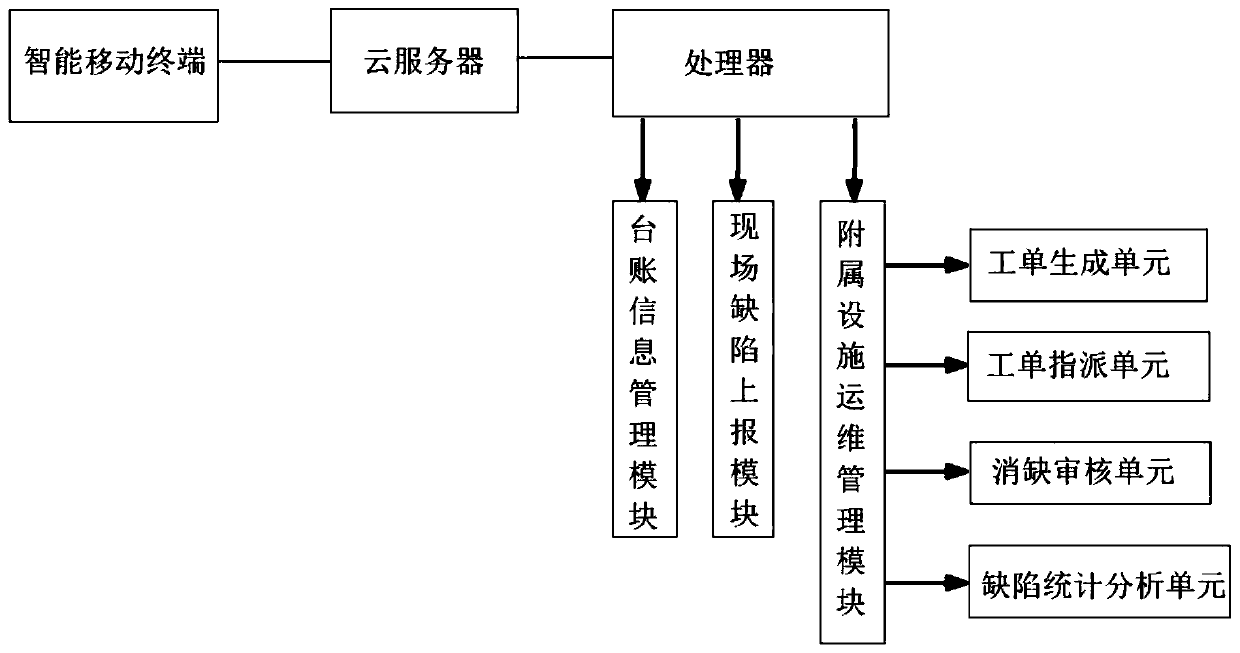

[0037] In one or more embodiments, a device for defect analysis and closed-loop management of substation auxiliary equipment is disclosed, including a processor, and the processor includes: a ledger information management module, a field defect reporting module, and an auxiliary facility operation and maintenance management module .

[0038] In this embodiment, the ledger information management module is used to realize unified maintenance and management of basic information of substation auxiliary equipment. By combing and classifying the substation auxiliary facilities categories, a unified ledger information model is established to realize the standardized management of substation auxiliary equipment ledger information. The information model includes the category of auxiliary facilities, facility name, model, manufacturer, date of commissioning, voltage level, etc.

[0039] Among them, the categories and names of auxiliary facilities include:

[0040] 1. Fire fighting equ...

Embodiment 2

[0073] On the basis of Embodiment 1, this embodiment discloses a defect analysis and closed-loop management system for substation auxiliary equipment, such as image 3 As shown, it includes: an intelligent mobile terminal, a cloud server, and a defect analysis and closed-loop processing device for substation auxiliary equipment in Embodiment 1;

[0074] Use the smart mobile terminal to collect defect information on site and upload it to the cloud server. The cloud server transmits the information to the defect analysis and closed-loop processing device for substation auxiliary equipment. The defect analysis and closed-loop processing device for substation auxiliary equipment generates defects based on the received defect information. The work order is assigned to the corresponding operation and maintenance personnel, and at the same time, the equipment defect rate, defect elimination rate, and family defect prediction are analyzed according to the defect work order information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com