Joint flange using thickness-increased and cutting-processed pipe and method for manufacturing same

A technology for joining flanges and pipe bodies, which is applied in the direction of manufacturing tools, metal processing equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of a large number of assembly work and increase manufacturing costs, and achieve the goal of reducing production time and production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, a joining flange using a thickened and processed pipe body and a manufacturing method thereof according to specific embodiments of the present application will be described with reference to the accompanying drawings.

[0029] In this procedure, the thickness of lines, the size of elements or the like illustrated in the drawings may be particularly exaggerated for clarity and convenience of description. The terms to be described below are terms defined in consideration of the functions in this application, and may vary depending on the user's or operator's intention or implementation. Therefore, such terms should be defined based on the entire content of the specification of the present application.

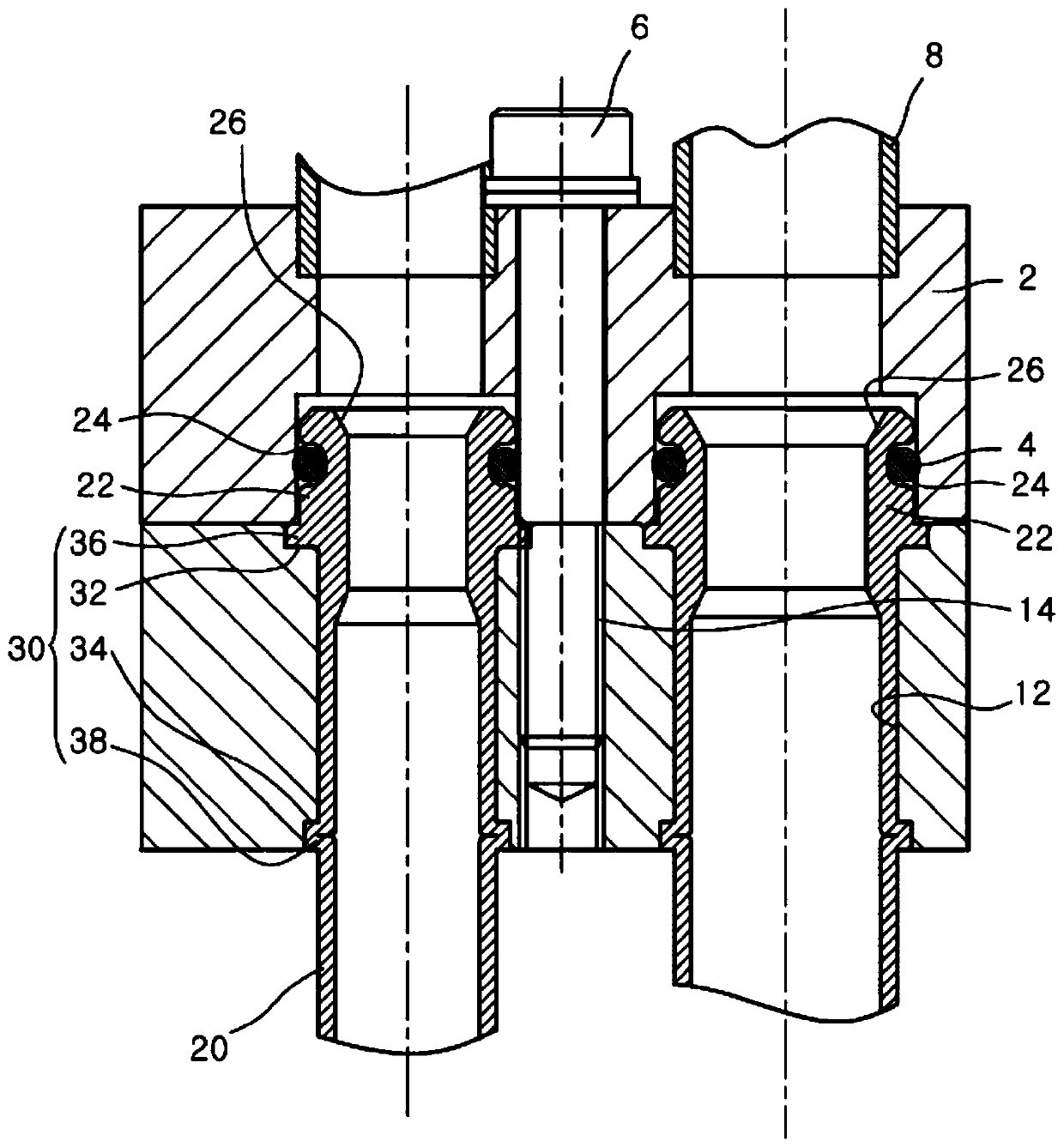

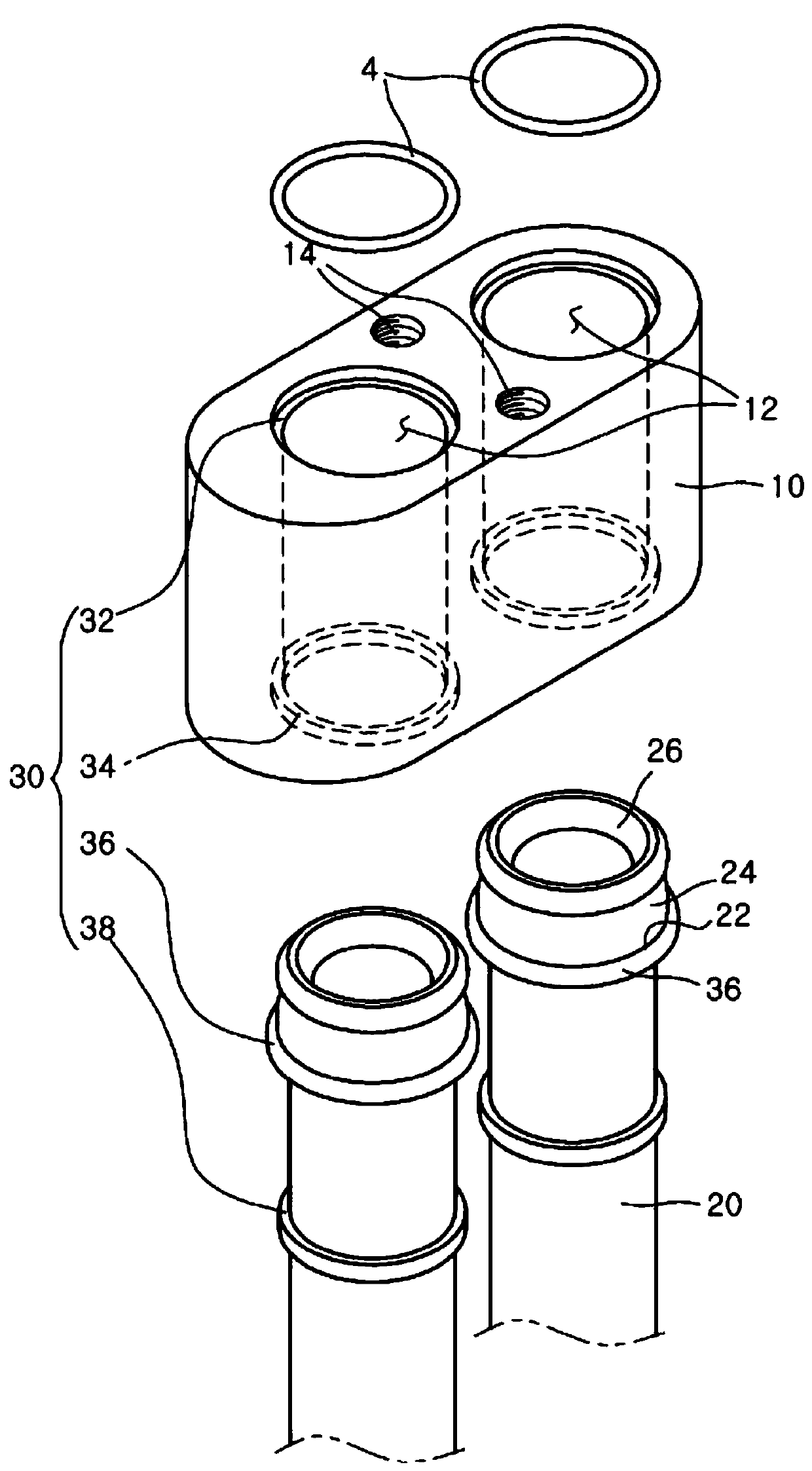

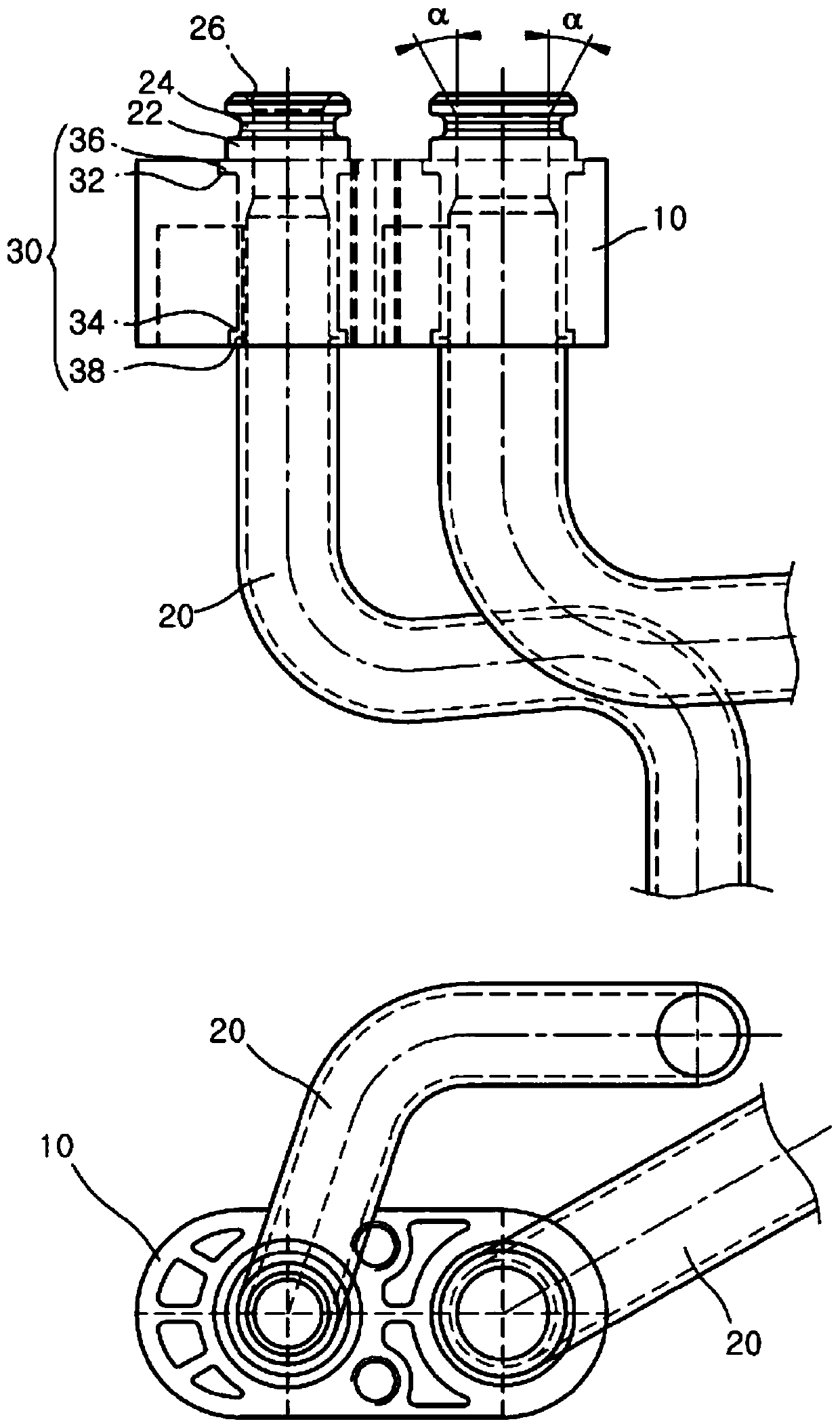

[0030] figure 1 It is a cross-sectional view of a state where a joint flange using a thickened and processed pipe body is assembled to a target flange according to a specific embodiment of the present application; figure 2 is an expanded perspective view of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com