Method applied to condenser inlet and outlet water chamber assembling and welding

A technology of import and export and condenser, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that manpower is difficult to meet machining requirements, and there is no setting tool.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

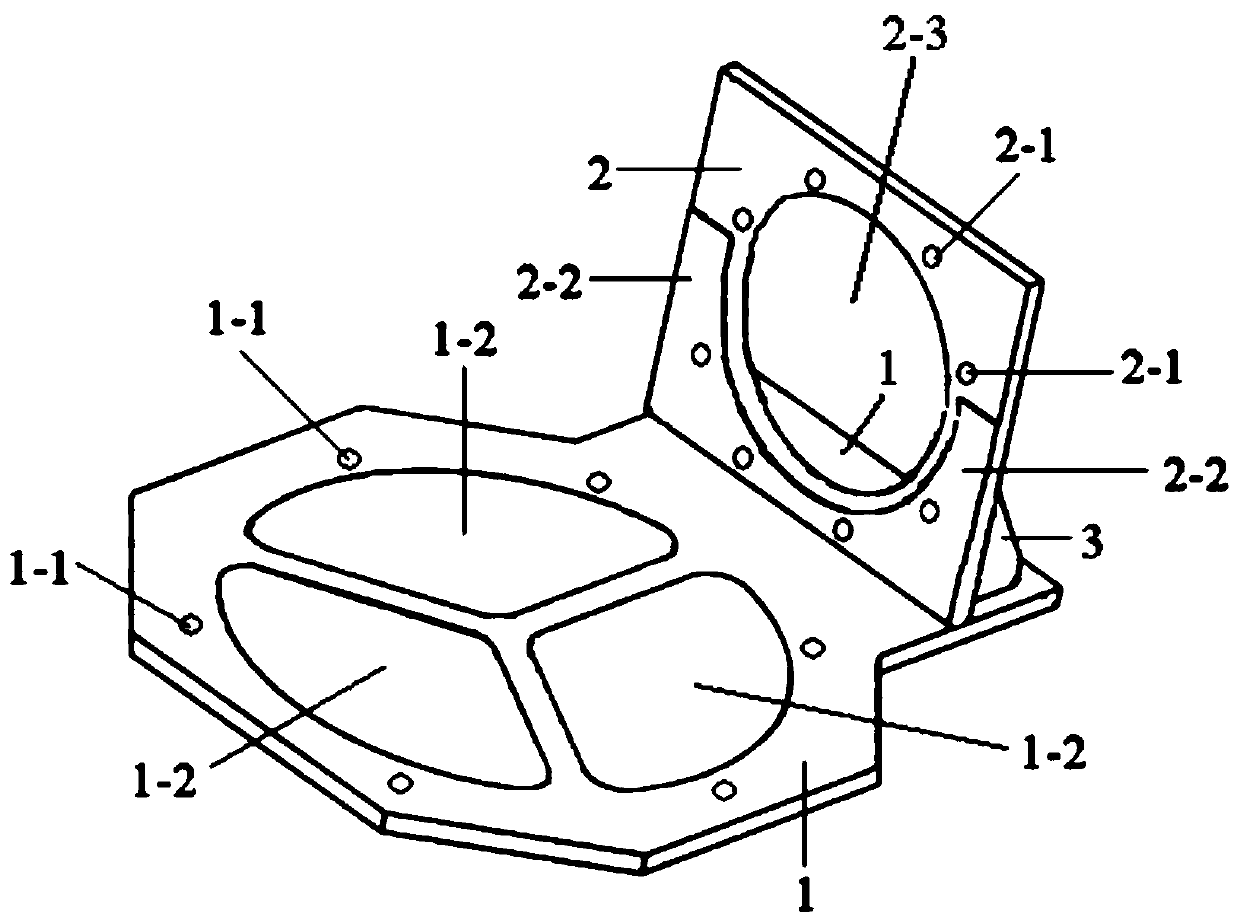

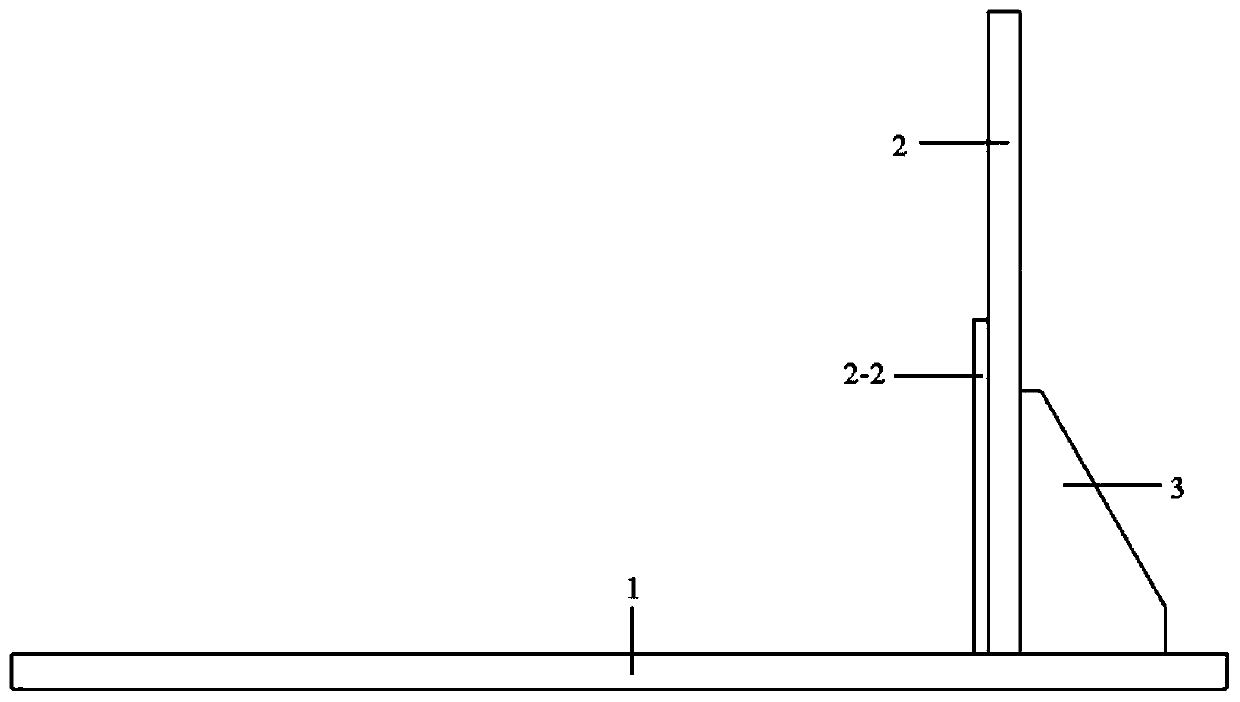

[0017] Specific implementation mode 1: This implementation mode is a method for welding the inlet and outlet water chambers of the condenser, which is carried out according to the following steps:

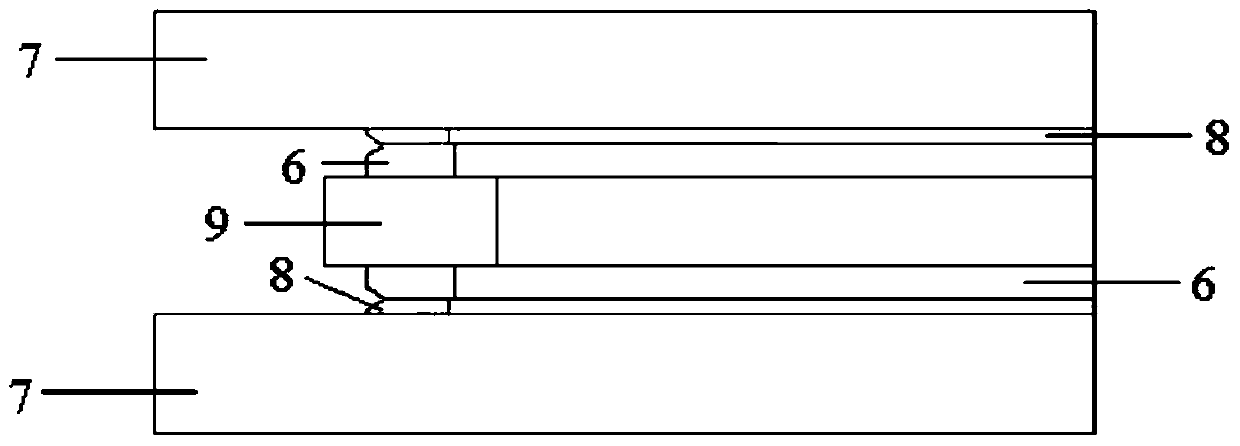

[0018] 1. Thermal leveling: if figure 1 As shown, thermal leveling: First, spot weld one end face of the two carbon steel flanges 6 on the two end faces of the welding base plate 9, and then assemble and weld the other end faces of the two carbon steel flanges 6 respectively. The cupronickel lining plate 8 is compacted with the upper and lower pressure plates 7, and then the entire workpiece is placed in the annealing furnace, and the welding stress between the carbon steel flange 6 and the cupronickel lining plate 8 is eliminated through heat treatment, the hardness is reduced and Make it level and complete the leveling work. The middle part is taken out from the two pressure plates, and the welding base plate 9 is removed to obtain the head flange and the connecting flange respe...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the other end faces of the two carbon steel flanges 6 are assembled and welded respectively, and a cupronickel liner 8 is welded together by argon arc welding. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the heat treatment process in Step 1 is as follows: the temperature of entering and exiting the furnace is 140°C-150°C, the heating and cooling rate is 95°C-100°C, and the heat treatment temperature 570 ℃ ~ 590 ℃, keep warm for 2 hours. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com