Electric hair cutter and control method thereof

A control method and the technology of electric clippers, which are applied in metal processing and other directions, can solve the problem of inconvenient adjustment of the length of the matching comb, and achieve the effects of saving shell space, convenient holding, and precise length change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

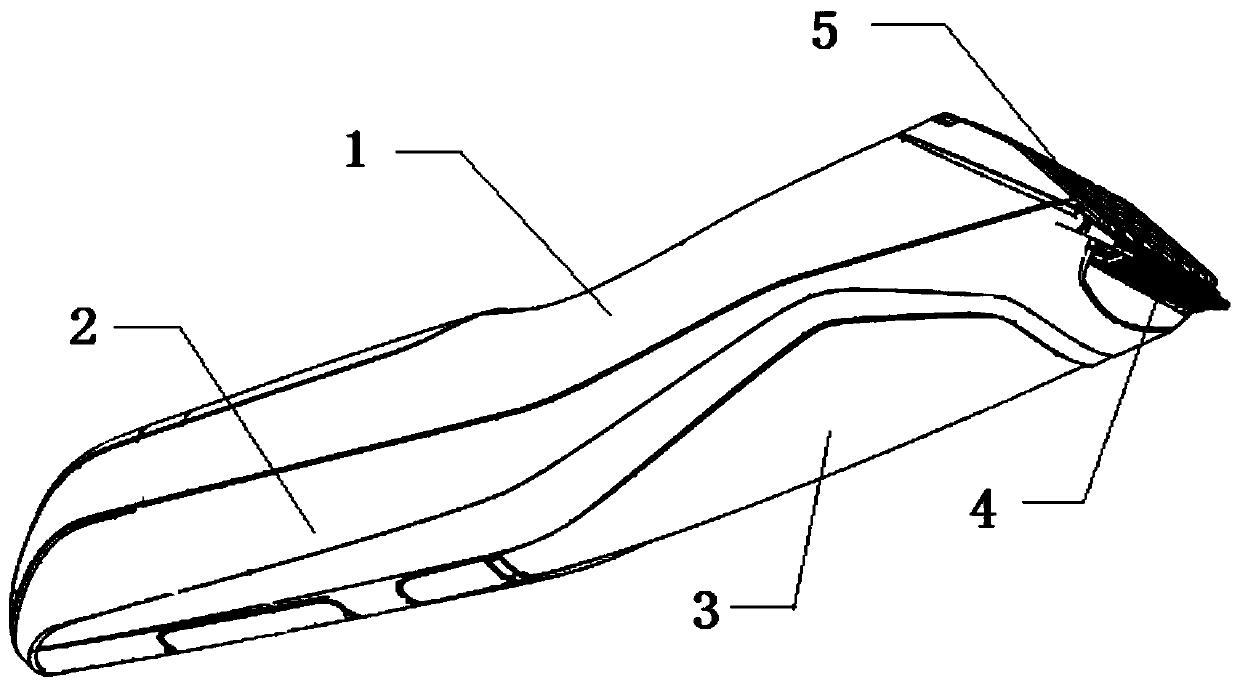

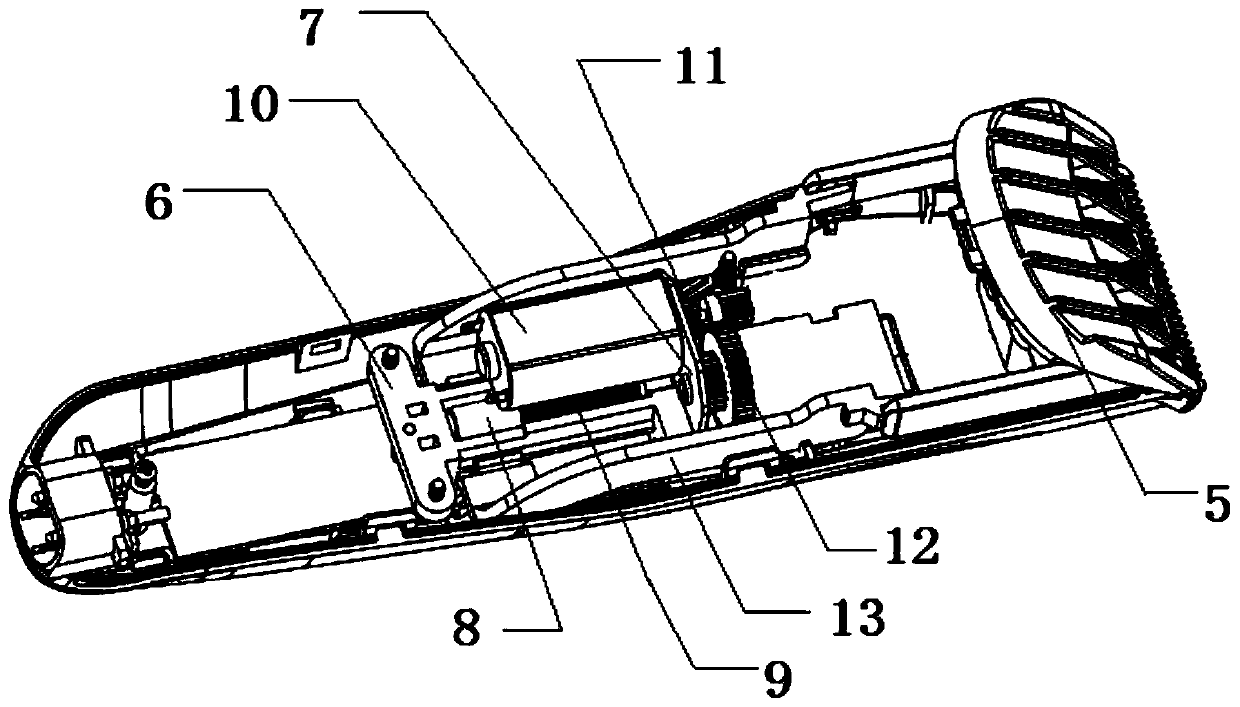

[0054] The first embodiment is basically as attached figure 1 Shown: electric clippers, including a shell and a blade assembly 4 and a comb 5 installed at the front end of the shell. The front end of the housing refers to the end of the electric clipper close to the hair during operation. The shell includes an upper shell 1 and a lower shell 2 buckled with each other. The lower shell 2 is equipped with a touch panel 3 for adjusting the extension length of the comb 5. When the touch panel 3 has multiple gears, the length of the comb 5 protruding from the shell is different when different gears are touched.

[0055] The blade assembly 4 is driven by an electric mechanism installed in the housing for reciprocating motion. For its structure, please refer to the blade set and drive mechanism in the patent document of the publication number CN201633051U or other connection structures of existing electric clippers. This is the prior art. I will not repeat them here.

[0056] Such as fi...

Embodiment 2

[0068] The difference between this embodiment and the first embodiment is that the driving part in this embodiment is a nut, and the driven part is a screw. The rear end of the screw is connected to the movable seat through a bearing, so that the screw can rotate relative to the movable seat and at the same time can drive the movable seat to move back and forth.

Embodiment 3

[0070] The difference between this embodiment and the first embodiment is that the detector in this embodiment adopts a photoelectric encoder, and the photoelectric encoder is electrically connected to the base of each triode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com