Composite to-go box

A packaging box and composite technology, applied in packaging, transportation, packaging, containers, etc., can solve problems such as easy overflow from packaging boxes, and achieve the effects of easy mass production, easy bag handling, and uniform force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

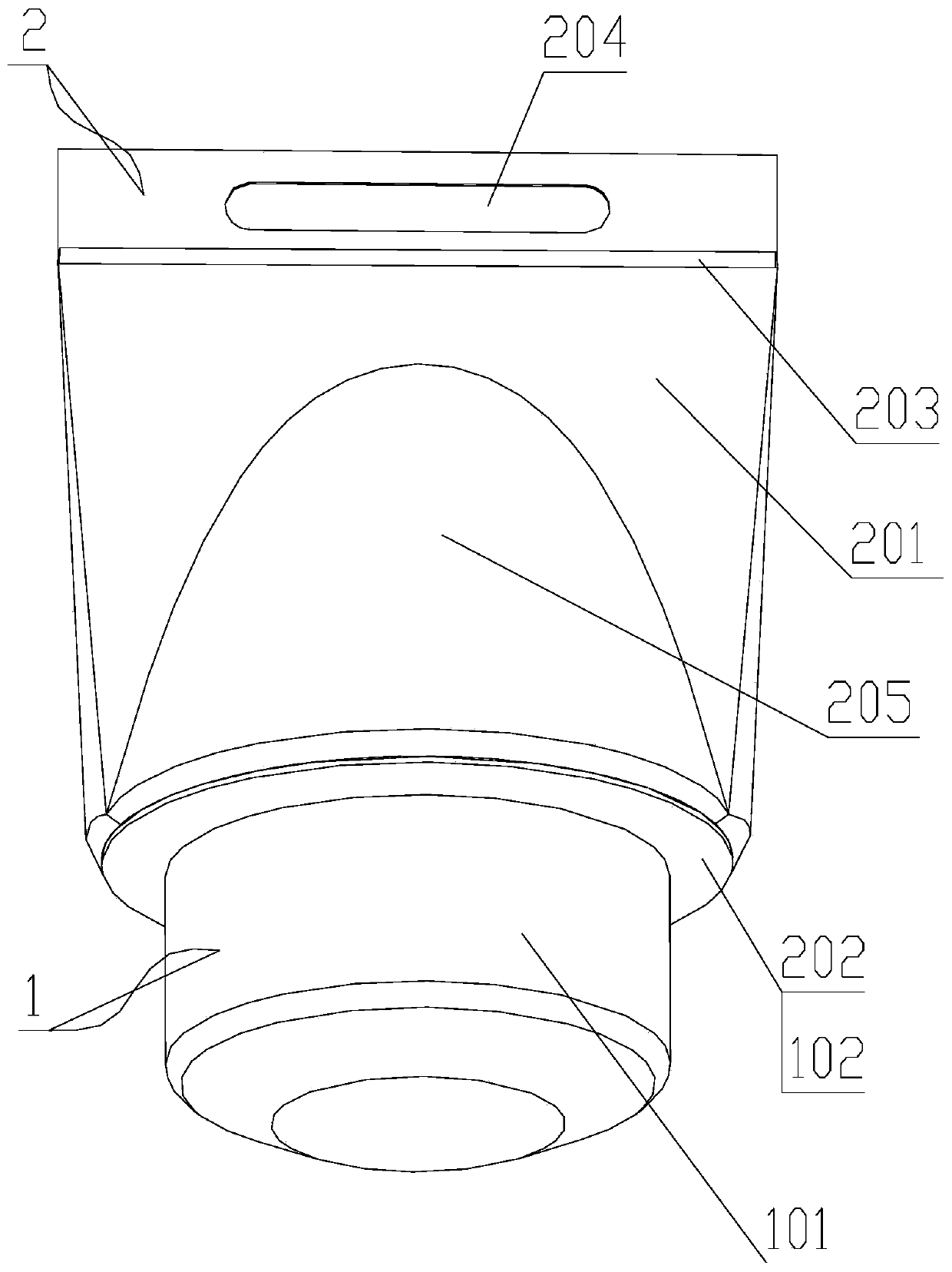

[0028] Embodiment one: if figure 1 As shown, a composite packaging box according to the present invention includes a bowl 1 and a cylindrical or inverted conical bag 2, the bowl 1 includes a bowl body 101, a bowl edge 102, cylindrical or inverted conical The bag 2 includes a cylindrical or inverted tapered bag body 201 , a bottom opening edge 202 , a straight-shaped sealing structure 203 , a handle structure 204 , and a convex or concave curved surface structure 205 .

[0029] The bowl 1 is located below the cylindrical or inverted conical bag 2, the top and bottom of the cylindrical or inverted conical bag 2 are open, and the bottom opening edge 202 of the cylindrical or inverted conical bag 2 is in contact with the bowl 1. The ring-shaped areas of the edge 102 of the mouth of the bowl fit each other, seamlessly overlap or seamlessly butt, specifically, the bottom opening edge 202 of the cylindrical or inverted tapered bag body 2 can be bonded with a heat-pressing plastic sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com