Ground asphalt cracking device for road construction

A technology for road construction and asphalt, which is applied in the field of ground asphalt cracking devices for road construction, which can solve problems such as incomplete ground cracking, adjustment of cracking angles, damage to cracking mechanical and electrical components, etc., to achieve safe and convenient use, increase shock absorption protection, Scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

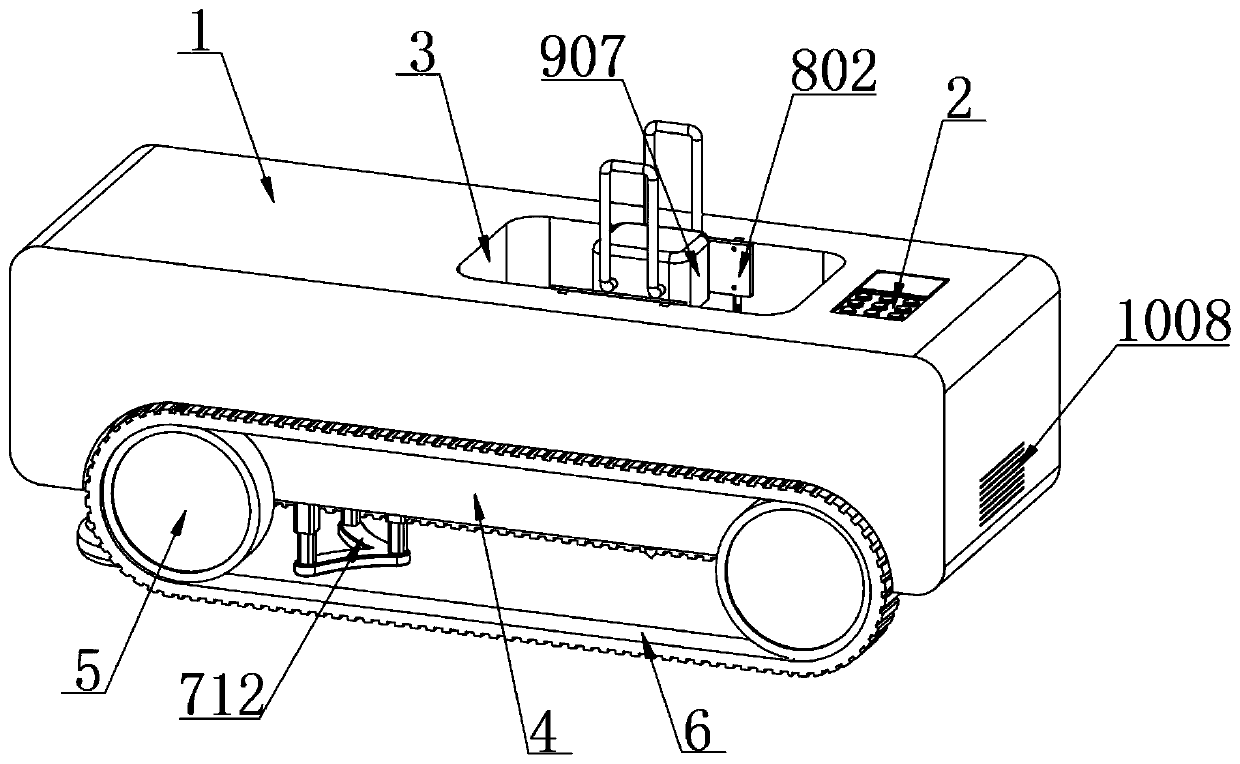

[0042] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a ground asphalt breaking device for road construction, including a breaking car body 1, a control switch 2 is embedded in the top of the breaking car body 1, and the top of the breaking car body 1 corresponds to the control switch 2 One side is provided with an installation through hole 3, and the two ends of the broken vehicle body 1 are symmetrically provided with an installation groove 4, and the inner wall of one end of the installation groove 4 is symmetrically rotated and connected with a running wheel 5, and an anti-skid track 6 is fixedly connected between the running wheels 5 ;

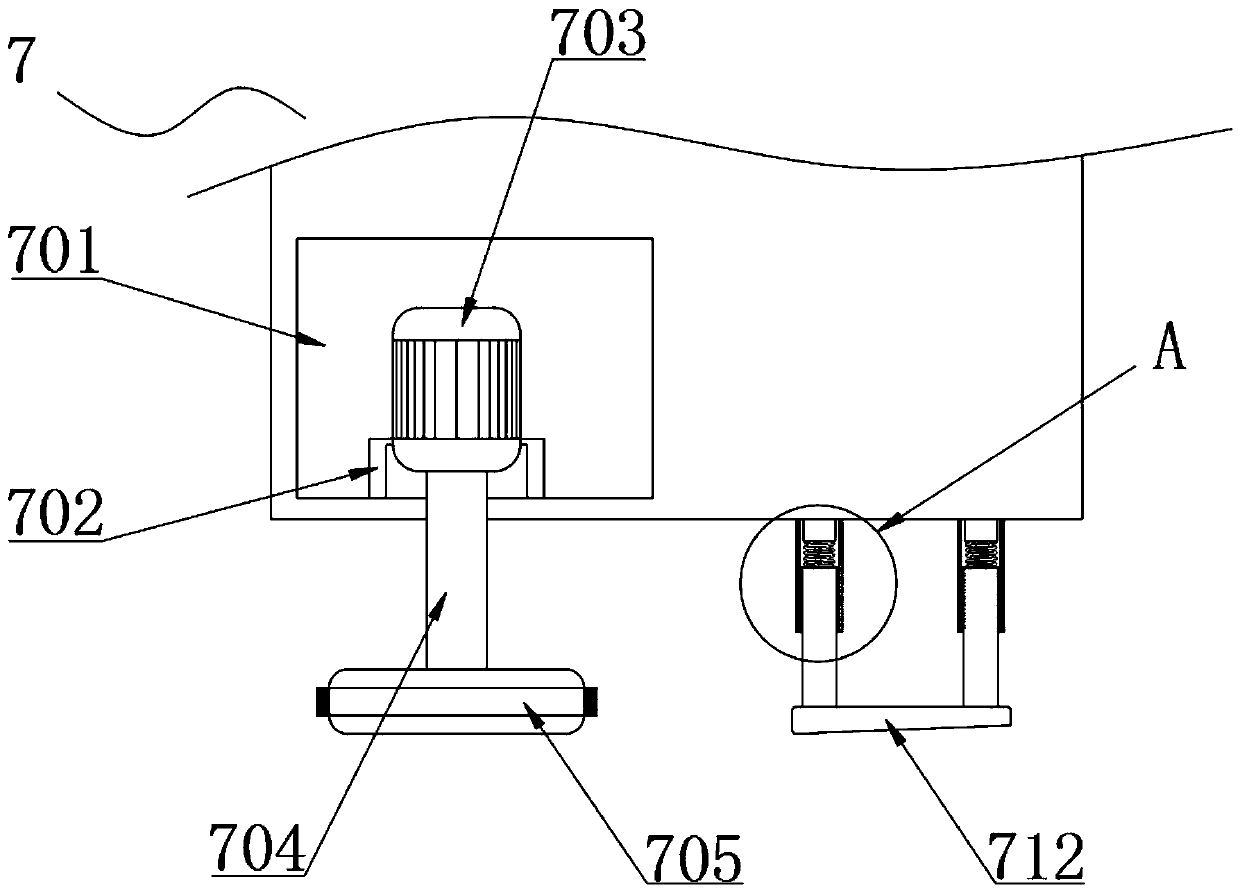

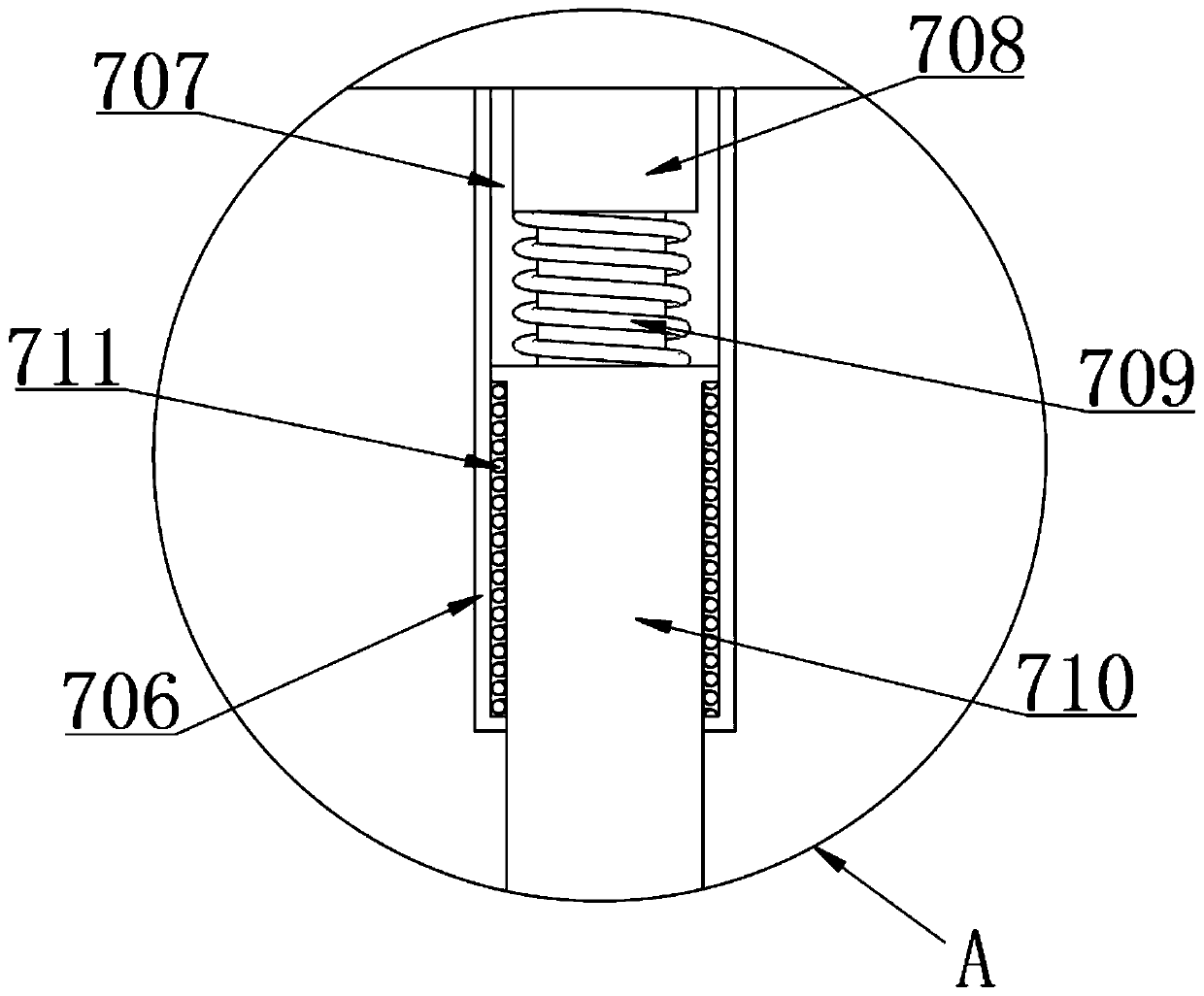

[0043] The bottom end of the broken car body 1 is provided with a slag pushing and cleaning mechanism 7, and the slag pushing and cleaning mechanism 7 includes a mounting cavity 701, a mounting base 702, a driving motor 703, a rotating shaft 704, a cleaning runner 705, a fixed rod 706, and a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com