Hydraulic system for molding machine, in particular for press casting machine

A hydraulic system and molding machine technology, applied in mechanical equipment, fluid pressure actuating devices, servo motors, etc., can solve problems such as damaged components, and achieve the effect of reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

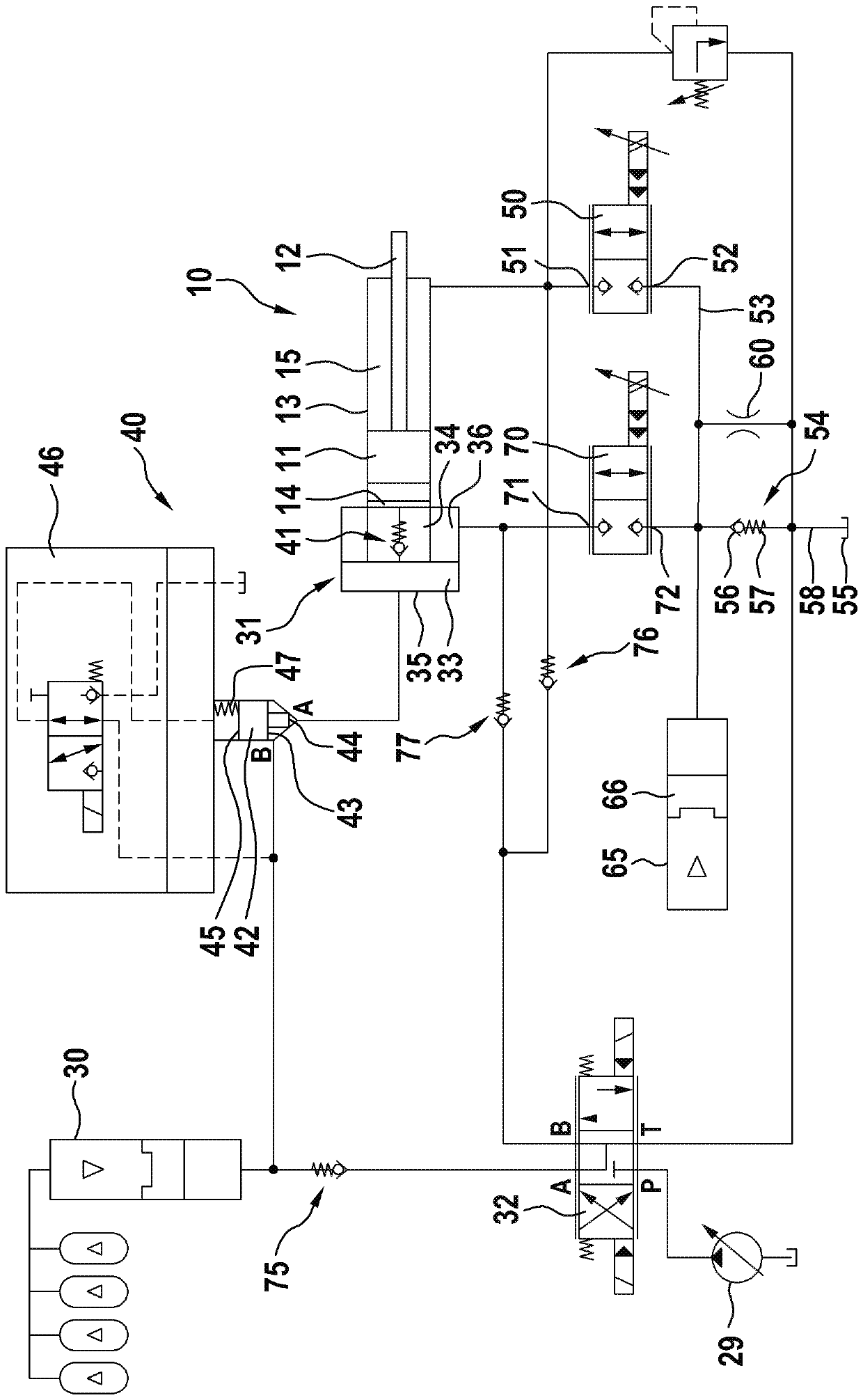

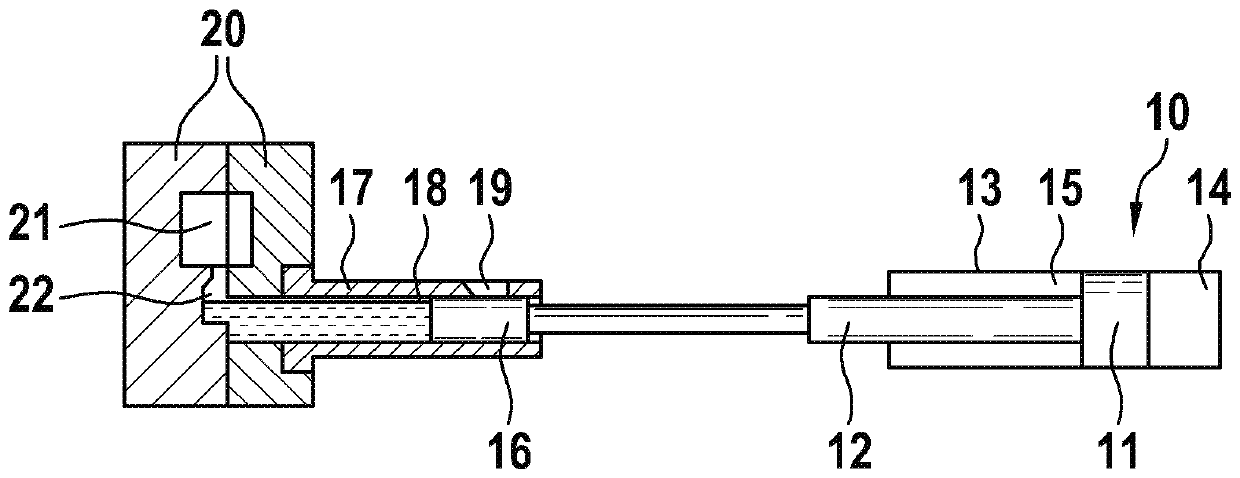

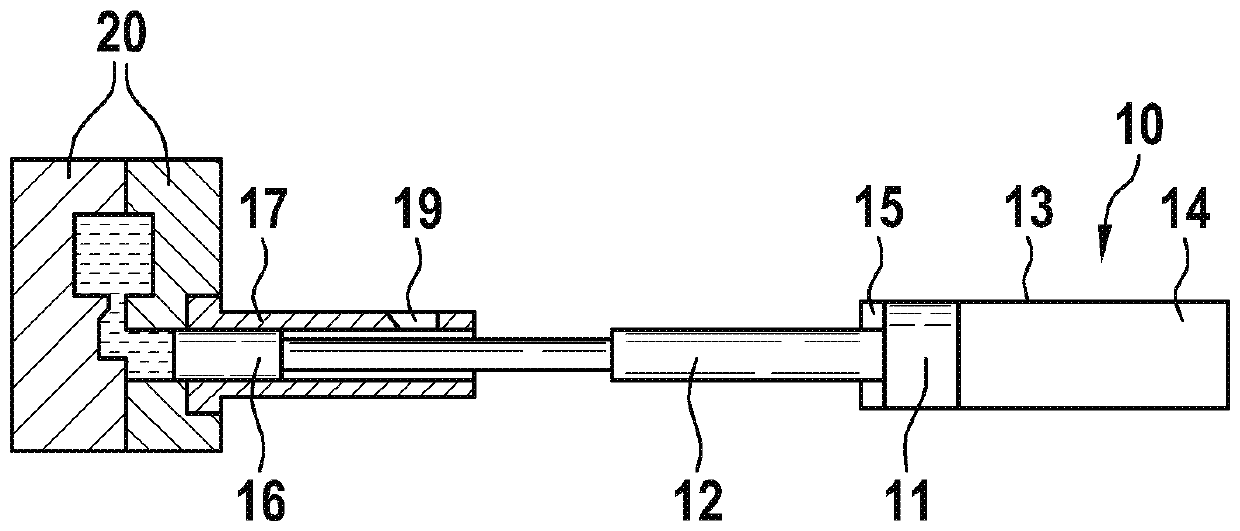

[0027] according to Figures 1 to 4 , the die-casting machine comprises an injection cylinder, which is hereinafter referred to as casting cylinder 10 because of its application in the die-casting machine, and which is configured as a differential cylinder and has a piston 11 and a piston rod 12, which from One side of the piston 11 begins to extend through the interior of the casting cylinder and out of the housing 13 of the casting cylinder on the cover. The completely cylindrical bottom-side pressure chamber 14 and the annular rod-side pressure chamber 15 are separated from one another in the interior of the casting cylinder 10 by the piston 11 .

[0028] Fastened to the piston rod 12 is a cast piston 16 which is linearly displaceable in a spray chamber 18 formed in a spray sleeve 17 . A filling opening 19 is located in the injection sleeve 17 for the liquid or pasty forming material from which the workpiece to be formed is to be formed. The injection sleeve 17 is assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com