Combined tenon structure of panel and leg and roof boardings of solid wood furniture and manufacturing method

A technology of legs and panels is applied in the field of combined tenon structure of solid wood furniture, which can solve the problems of destroying the mechanical structure and weakening the structural strength, and achieves the effects of increasing the mechanical strength, avoiding the replacement of milling cutters and improving the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is based on Figure 1 to Figure 4 The specific embodiment of the present invention is further described:

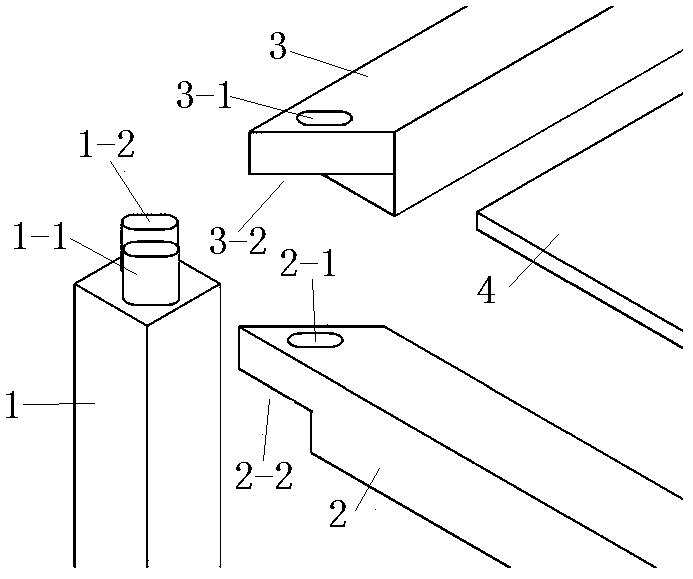

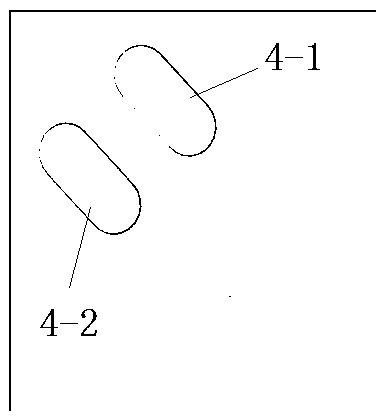

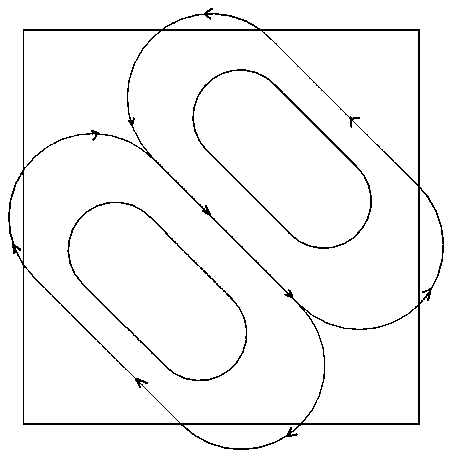

[0034] This embodiment provides a combination tenon structure of the legs of the solid wood furniture panel and the watch board, such as figure 1 as shown, figure 1 The leg part 1, the watch board one 2, the watch board two 3 and the panel 4 are partial structural diagrams, and the combined tenon structure of this embodiment specifically includes the panel 4, the watch board one 2, the watch board two 3 and the leg part 1, The top of the leg 1 is respectively provided with a first oval tenon 1-1 and a second oval tenon 1-2, and the lower surface of one end of the watch board one 2 is milled with a first notch 2-2 and the end There is a first mortise 2-1 on the surface, the first mortise 2-1 is located directly above the first slot 2-2, and the lower surface of one end of the watch plate 2 3 is milled with a second slot 3-2 And the end surface is pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap