Objective table for detecting hardness of ring type part, micro hardness tester and detecting method thereof

A technology of microhardness and stage, applied in the field of stage, can solve the problems of difficult detection work, time-consuming and distracting, and the detection piece is easy to be touched and moved, so as to prevent axial movement and achieve good self-locking effect. , Improve the effect of clamping reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

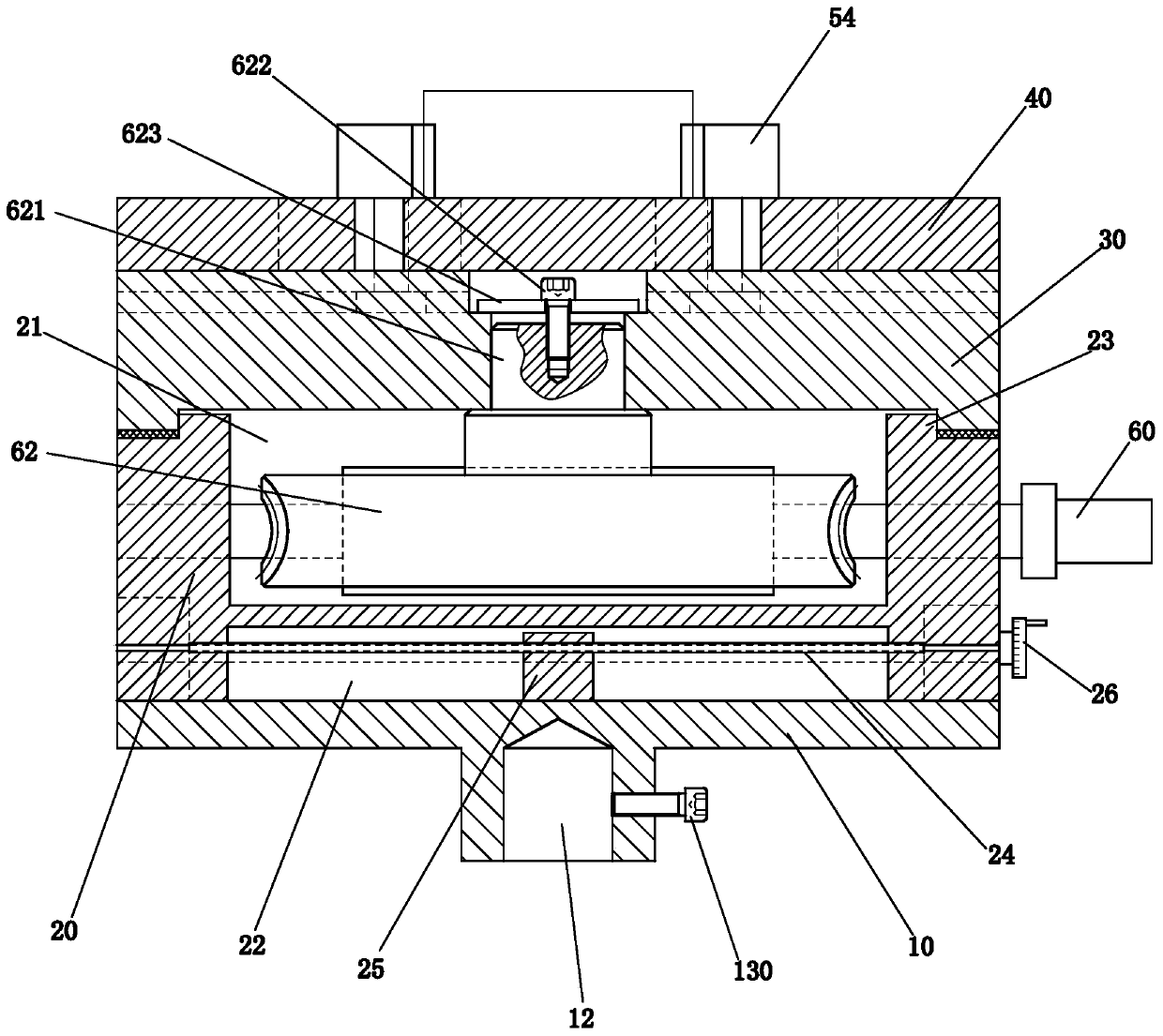

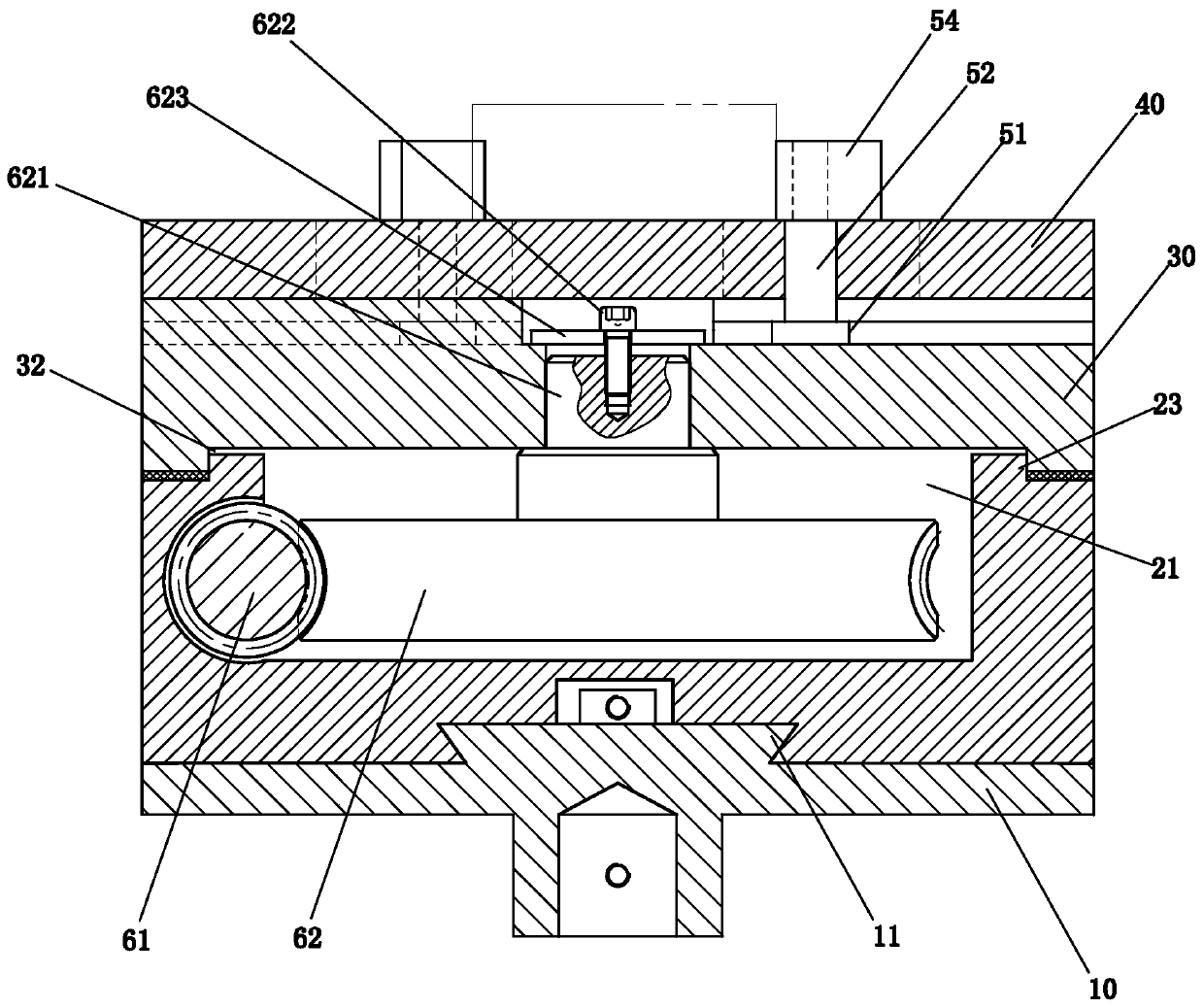

[0047] Please check Figure 2 to Figure 11 , a preferred embodiment of the stage used for hardness detection of ring parts, the described stage for hardness detection of ring parts includes a base part, a guide groove disc 30, an eccentric groove disc 40 and a positioning Locking member 50.

[0048] In this embodiment, the base part includes a base 10 and a horizontal worktable 20 that can move laterally along the base 10 , and the horizontal worktable 20 is located above the base 10 .

[0049]The top surface of the horizontal table 20 is provided with an assembly cavity 21, and the bottom surface is provided with an installation groove 22, and the top surface of the horizontal table 20 is provided with a round platform protrusion 23, and the center of the circular table protrusion 23 coincides with the center of the horizontal table 20. . like figure 2 As shown, the base 10 and the horizontal worktable 20 adopt a screw nut transmission mechanism for transmission cooperati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com