Method for predicting elasticity modulus of polycrystalline material

A technology of material elastic modulus and prediction method, which is applied in the fields of instrumentation, calculation, electrical and digital data processing, etc., can solve the problems of difficult to predict the elastic modulus of material structure, lack of theoretical models and technical means, and save experimental costs. , fast prediction, high matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

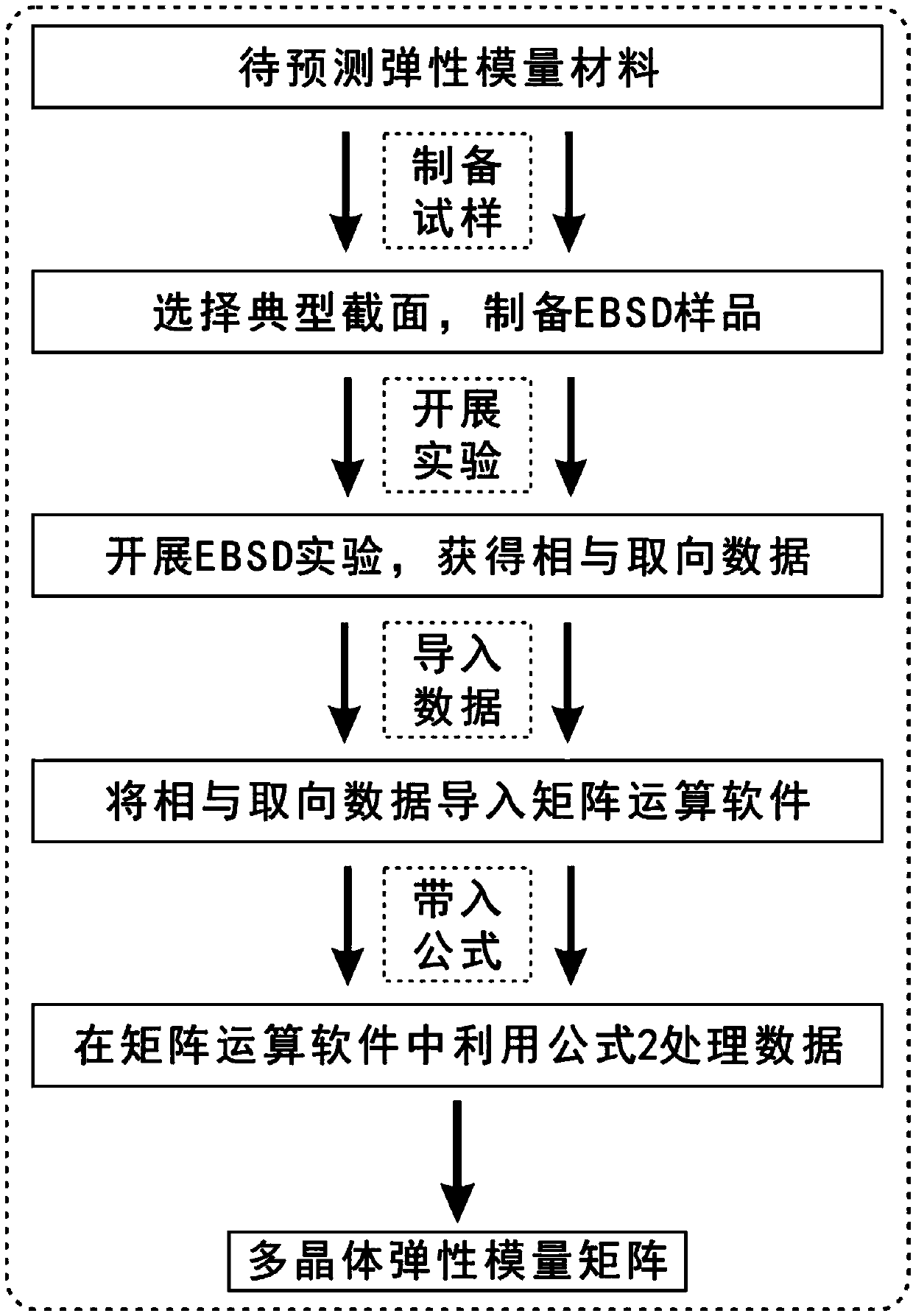

[0049] This example is the prediction and experimental verification of the elastic modulus of high-strength low-alloy steel. The process is as follows:

[0050] (1) Material:

[0051] High-strength low-alloy steel (H480LA), as-rolled, with a final rolling thickness of 1mm; the composition (wt%) is as follows:

[0052] C: 0.07%; Mn: 0.688%; Nb: 0.039%; Al: 0.033%; Si: 0.029%; P: 0.012%;

[0053] (2) Prediction process:

[0054] Step 1: Select interface samples to prepare EBSD samples.

[0055] Step 2: Carry out EBSD experiments to obtain phase and orientation information of representative regions.

[0056] Step 3: Input EBSD phase and orientation data into MATLAB software, use formula (2) to combine orientation data and corresponding single crystal modulus matrix for calculation, and obtain the predicted data of elastic modulus matrix.

[0057] Step 4: Carry out ultrasonic modulus measurement on the same material to obtain the experimental data of the modulus matrix.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com