A kind of equipment used to clean the inner wall of the factory building for secondary treatment

A secondary treatment and workshop technology, applied in cleaning-related fields, can solve problems such as human environmental hazards, large harmful substances, high diffusivity and corrosiveness of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

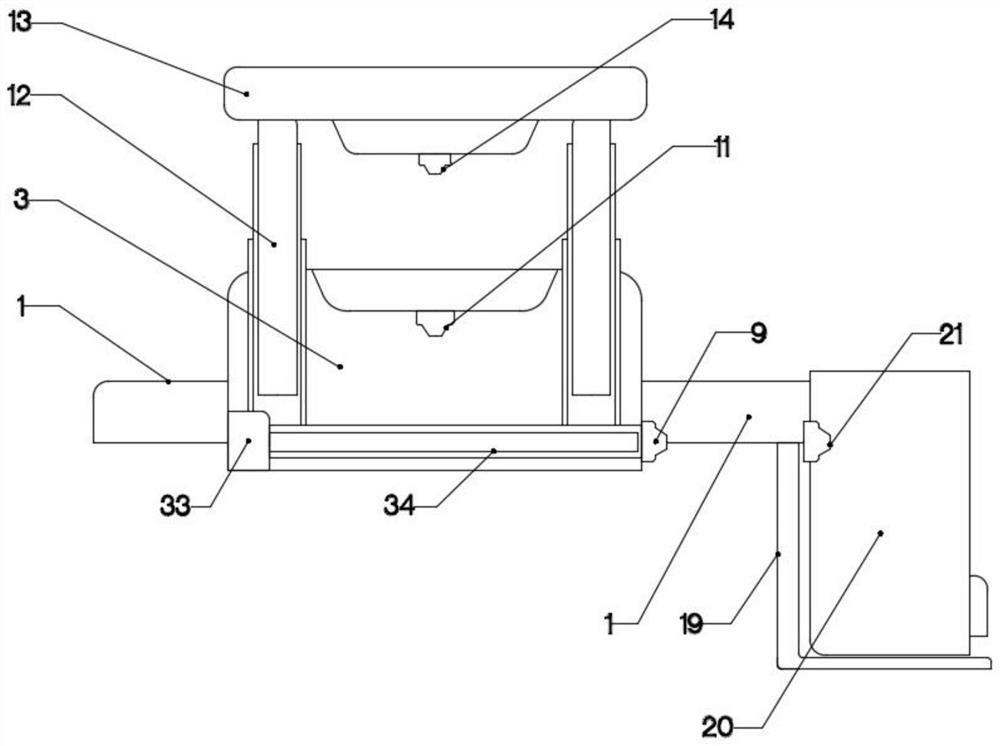

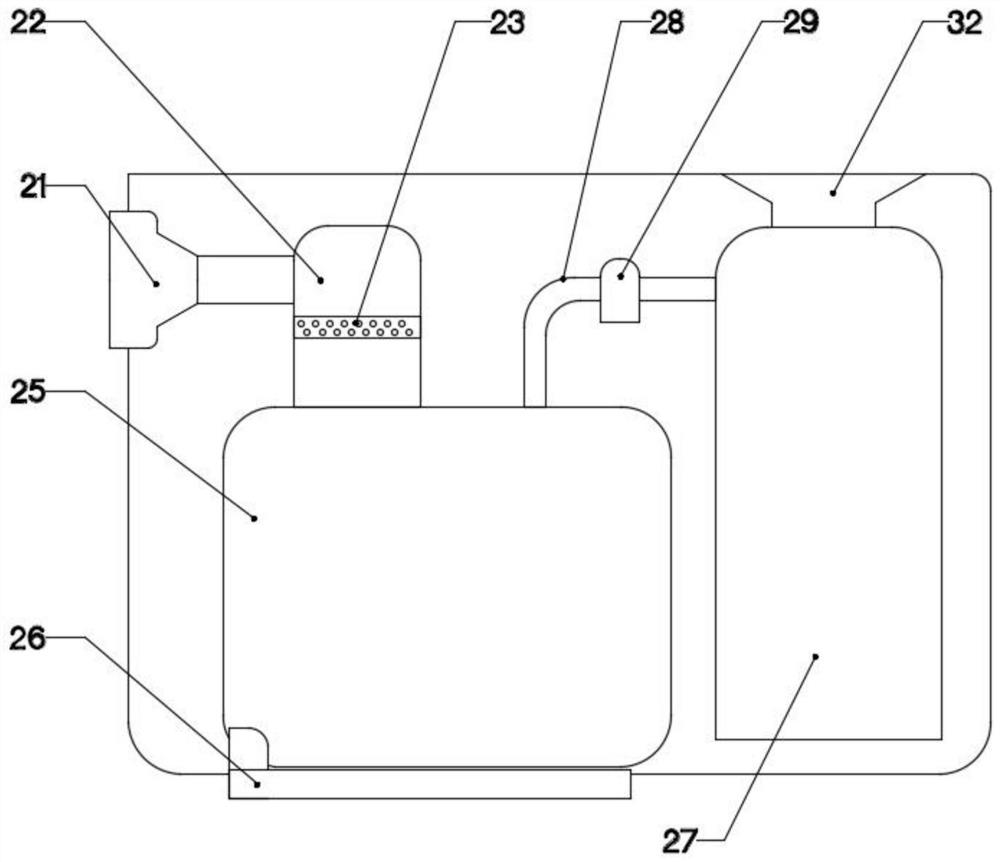

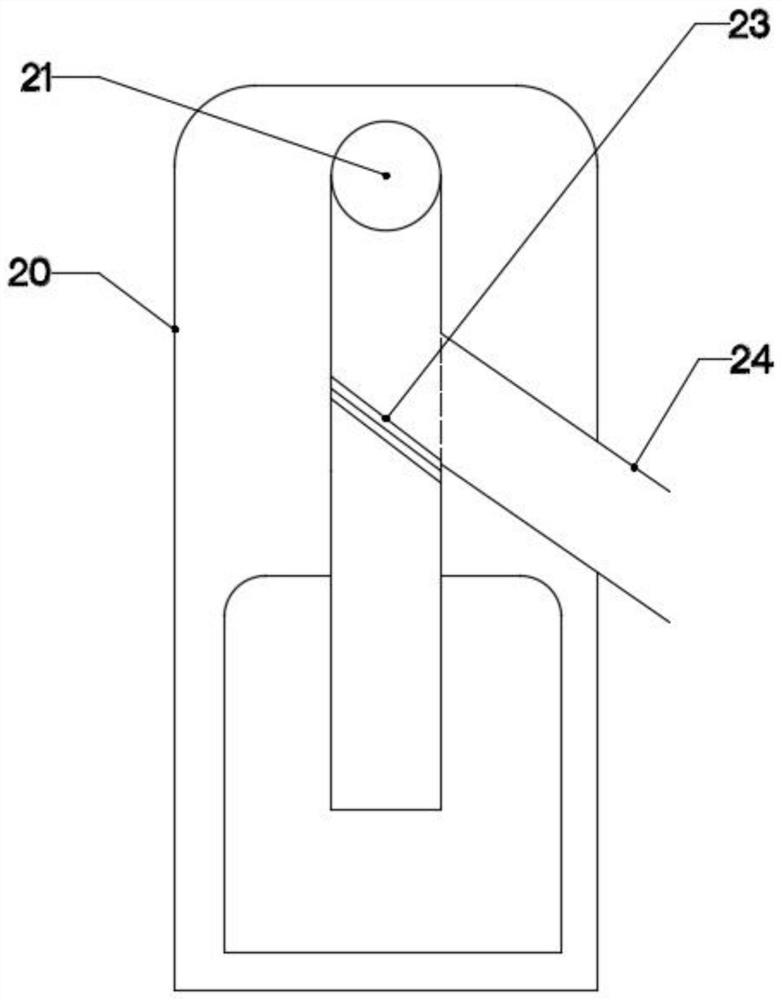

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 shown.

[0021] In this embodiment, the large-area inner wall can be cleaned up in an orderly manner through the function of the cleaning range adjustment device, the harmful substances on the side surface of the inner wall can be effectively collected through the function of the attachment cleaning device, and the harmful substances can be collected through the function of the harmful substance filtering device. A certain chemical reaction is carried out on the collected harmful substances, so as to achieve the purpose of harmless discharge.

[0022] In the first step, due to the characteristics of the inner wall structure of the workshop, the equipment is designed to be cleaned from bottom to top. When cleaning is required, the controller controls 7 hydraulic cylinders one 12 to elongate. At this time, the sealing interface 2 11 and the sealing socket 2 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com