Processing method of combined bipolar electric coagulation forceps, and electric coagulation forceps

A technology of bipolar electrocoagulation tweezers and a processing method, which is applied in the directions of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high product cost, high manufacturing cost, complicated assembling method and structure, etc., and achieves simple manufacturing steps, Best value for money, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

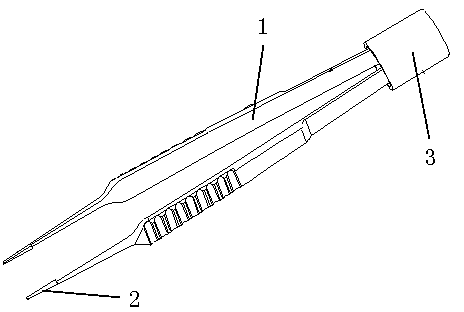

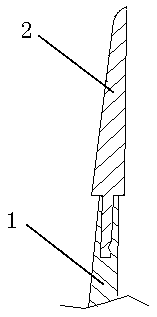

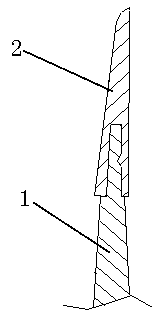

[0038] In the first embodiment, the forceps tip 2 includes a forceps tip body, a forceps tip connector integrally formed with the forceps tip body, the forceps tip connector is provided with a forceps tip groove, and the forceps body 1 is provided with The forceps body jack into which the forceps tip connector is inserted. The step 5) specifically includes inserting the forceps tip connector into the forceps body socket and filling the forceps tip groove with a metal material through a stamping method, so that the forceps body 1 and the forceps tip 2 are closely connected.

Embodiment 2

[0039] In the second embodiment, the forceps body 1 includes a forceps body body, a forceps body connection body integrally formed with the forceps body body, the forceps body connection body is provided with a forceps body groove, and the forceps tip 2 is provided with The forceps tip jack into which the forceps body connector is inserted. The step 5) specifically includes inserting the forceps body connector into the forceps tip insertion hole and filling the groove of the forceps body with a metal material 2 by a stamping method, so that the forceps body 1 and the forceps tip 2 are tightly connected.

[0040] The tweezers body 1 and the tweezers tip 2 need to adopt the specific structure of the application and use a stamping method to connect, so that the tweezers body 1 and the tweezers tip 2 are firmly connected, not easy to loose, and avoid paint blasting due to welding, or cumbersome assembly and easy loosening The phenomenon.

[0041] A combined bipolar electrocoagulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com