Double-shaft power head

A power head and rotating shaft technology, applied in the field of machinery, can solve the problems of energy saving, low work efficiency, large floor space, etc., and achieve the effects of high processing efficiency, convenient assembly, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

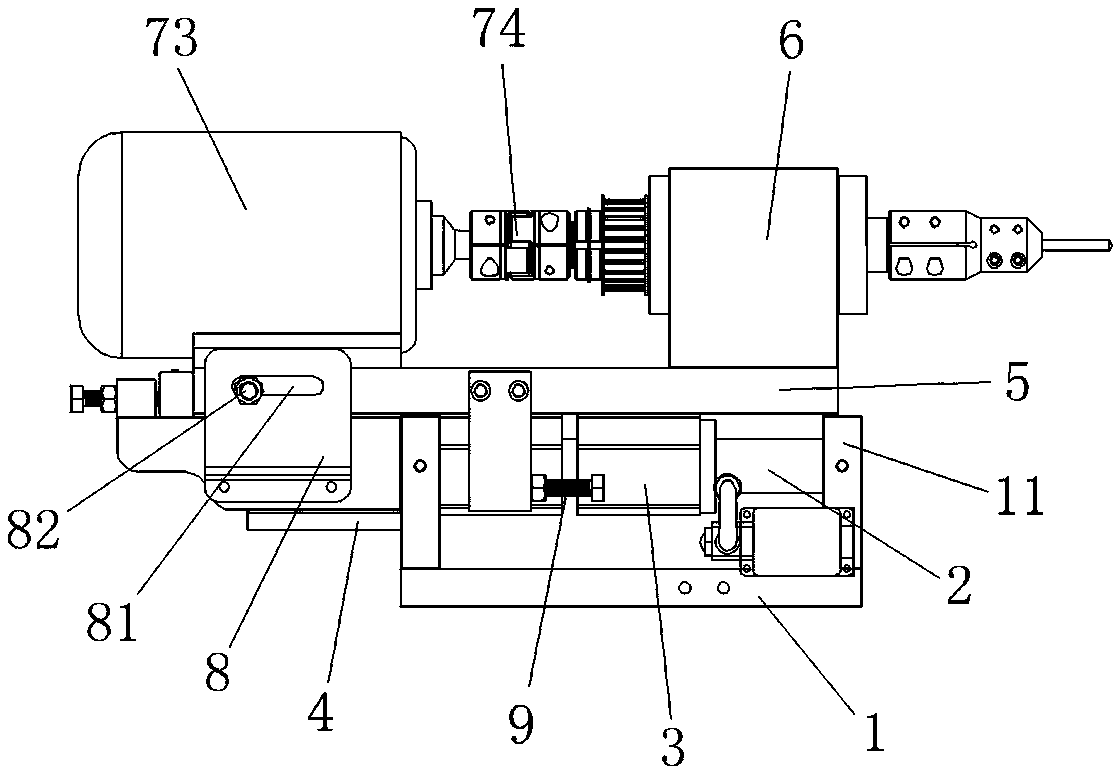

[0019] The dual-axis power head, such as figure 1 As shown, it includes a bracket 1 with support plates 11 at both ends, a guide shaft 2 passing between the two support plates 11, a linear bearing 3 sleeved on the guide shaft 2, and a device for driving the linear bearing 3 to move along the guide shaft 2. Cylinder 4, such as figure 1 As shown, there are two linear bearings 3 and they are fixedly connected together by a connecting piece 9, and the connecting piece 9 in this embodiment is a bolt.

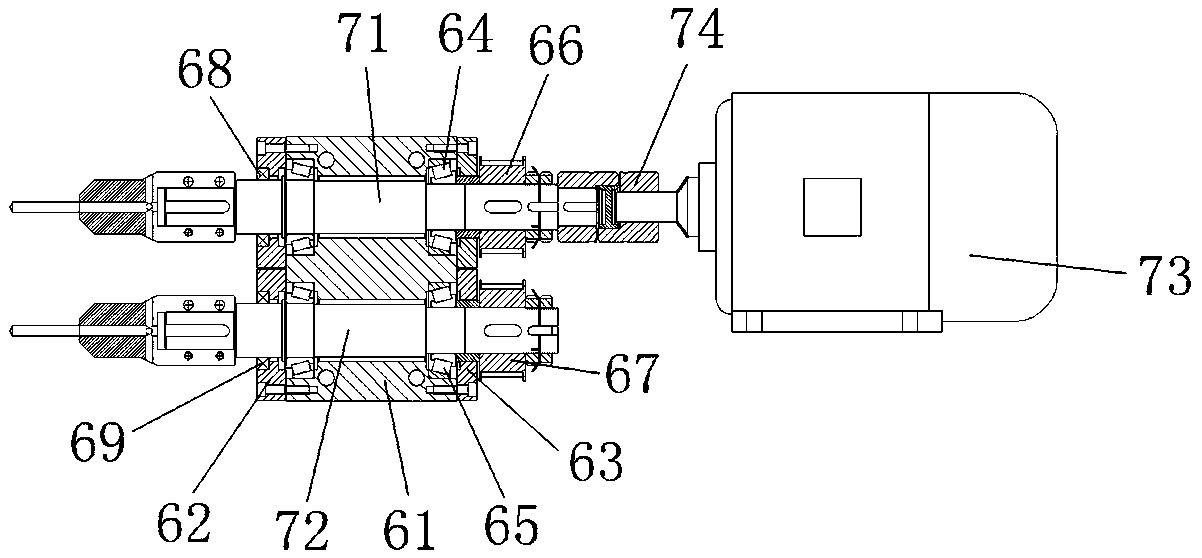

[0020] Two linear bearings 3 are located between two support plates 11, such as figure 1 As shown, a translation plate 5 is fixedly connected above the linear bearing 3, and a headstock 6 is arranged on the translation plate 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com