Single-motor driven type bolt stretcher gripper

A technology driven by a bolt tensioner and a single motor, which is applied in hand-held tools, manufacturing tools, etc., can solve the problems of large overall structure, high energy consumption, and inability to be widely popularized, and achieve the effect of simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

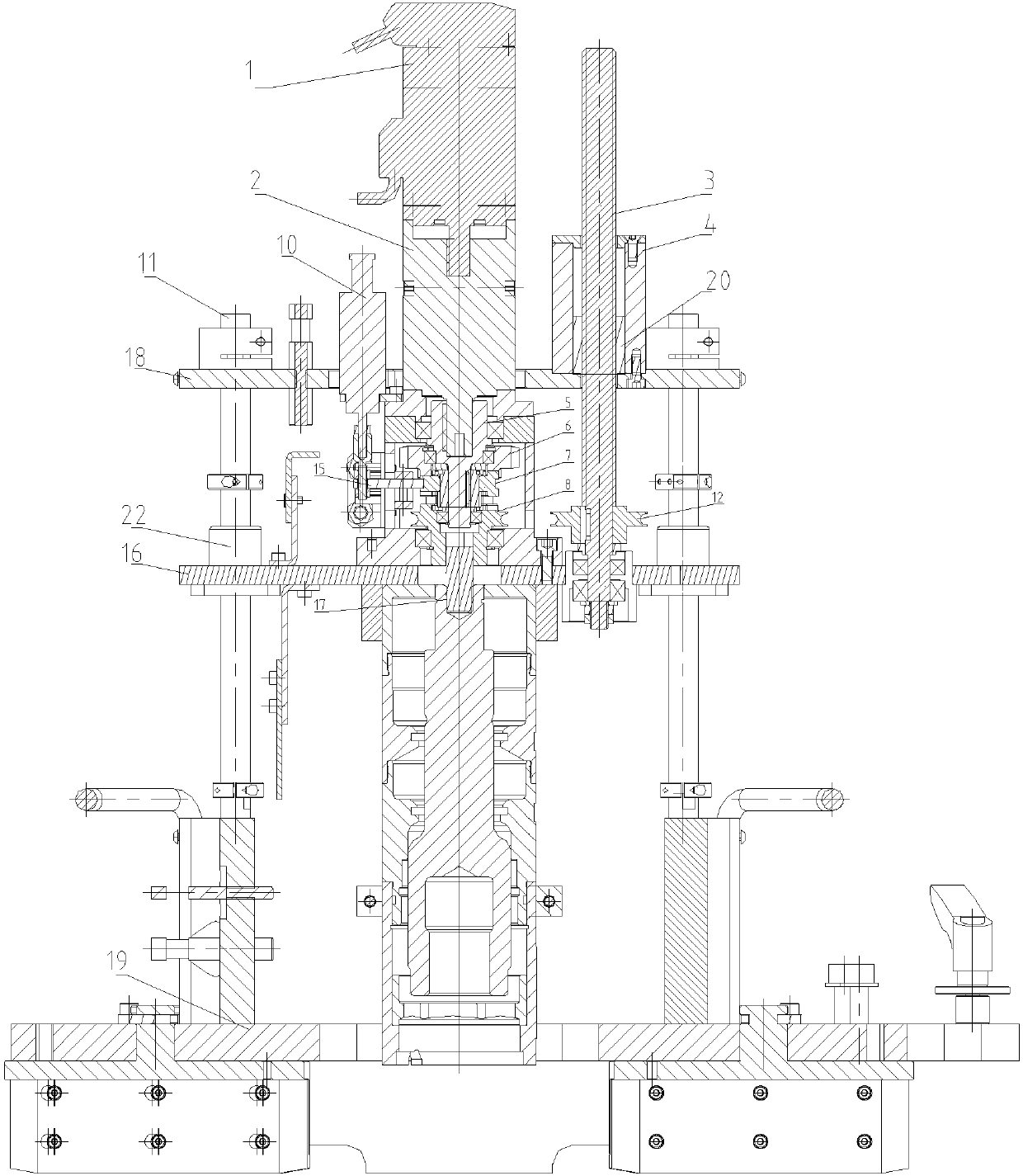

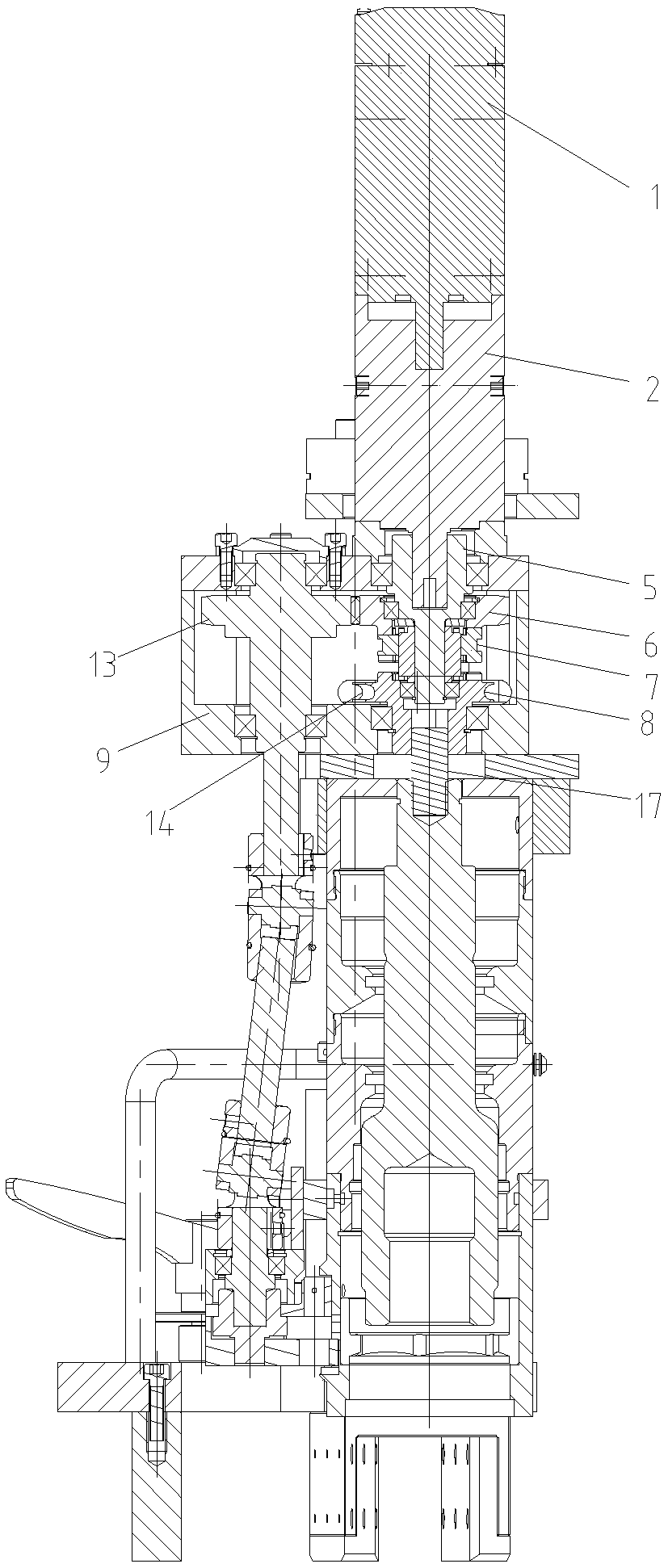

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0020] like figure 1 and figure 2 As shown, the gripper of the single-motor-driven bolt tensioner of the present invention includes:

[0021] Power device; guiding device; reversing device; lifting device; frame;

[0022] The frame includes a bottom plate 19 and a fixed plate 18 , and the fixed plate 18 is arranged directly above the bottom plate 19 .

[0023] The guiding device includes a guide post 11 and a linear bearing 22 , the bottom plate 19 is connected to the fixed plate 18 through the guide post 11 , and the linear bearing 22 is slidably arranged on the guide post 11 .

[0024] The power unit includes a motor 1 and a speed reducer 2 connected to the bottom side of the motor 1;

[0025] The reversing device includes an input shaft 5, a gear 6, a reversing wheel 7, a pulley shaft 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com