An automatic slicer for biomedical research experiments

A biomedical and experimental technology, applied in the field of biomedical research, can solve the problem of small cutting range of the cutter, and achieve the effect of large cutting range and widening cutting width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

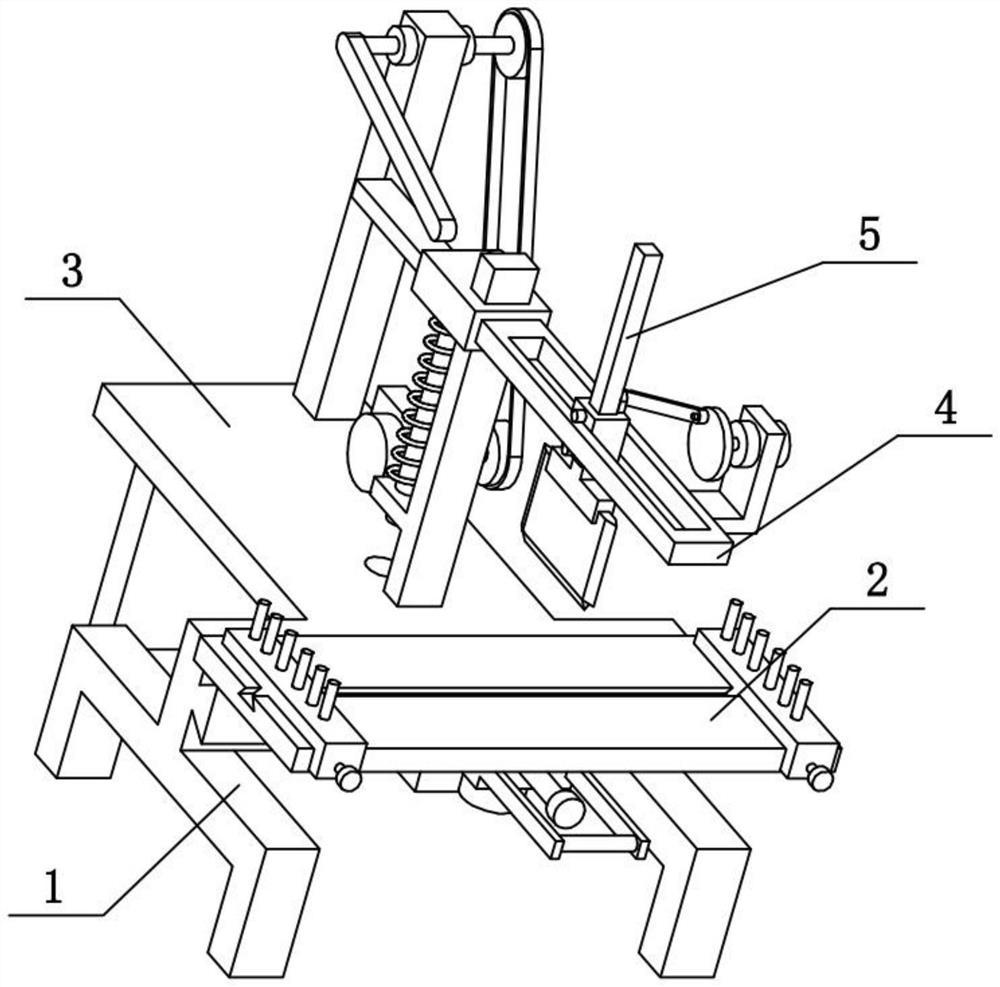

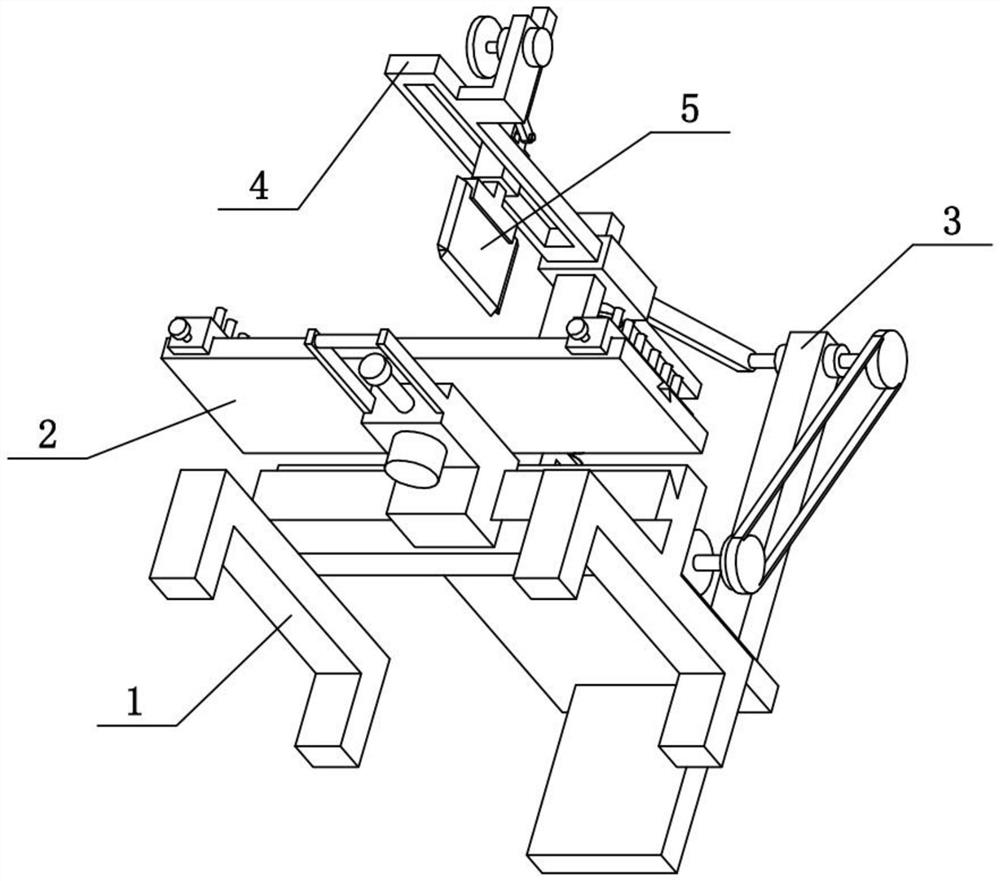

[0031] Combine below Figure 1-10 To illustrate this embodiment, the present invention relates to the field of biomedical research, more specifically, an automatic slicer for biomedical research experiments, including a support frame 1, a cutting table 2, a rear seat mechanism 3, a lifting cutting frame 4 and a cutting knife Component 5, the upper end of the cutting table 2 in the present invention is used to fix the medical materials for research, when the lifting cutting frame 4 moves down, the medicinal materials on the cutting table 2 can be sliced, and the cutting table 2 can be cut with the axis of the central axis 2-6 Rotate for the axis, and can move left and right, adjust the position of the medicinal material to slice the medicinal material, and the lower end, front end and rear end of the cutter 5-4 are all provided with blades, and the cutter 5-4 can also reciprocate back and forth during the downward movement Move, strengthen the cutting width of cutting knife 5-4...

specific Embodiment approach 2

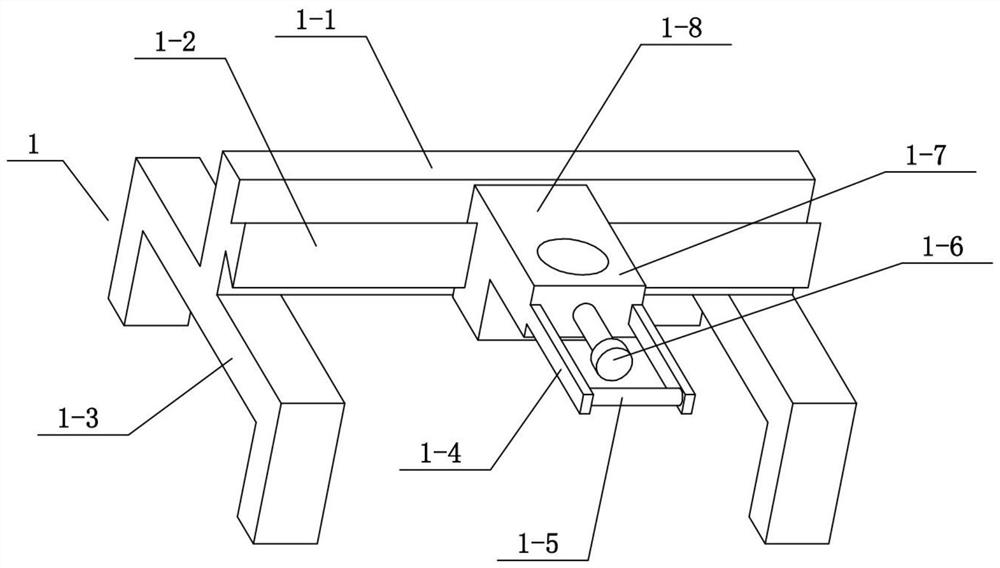

[0034] Combine below Figure 1-10To illustrate this embodiment, the support frame 1 includes a beam 1-1, a trapezoidal slide rail 1-2, a door frame 1-3, a fastening screw I1-6, a swivel seat 1-7 and a slider 1-8, The front end of the beam 1-1 is provided with a trapezoidal slide rail 1-2, and the slide block 1-8 is slidably connected to the trapezoidal slide rail 1-2, and the front end of the slide block 1-8 is fixedly connected with a plug-in swivel seat 1-7, and the plug-in swivel The front end of seat 1-7 is threadedly connected with fastening screw I1-6, and the left and right ends of crossbeam 1-1 are all fixedly connected with gantry 1-3. The two gantry frames 1-3 play the role of supporting the beam 1-1, and the slide block 1-8 can slide leftward or rightward on the trapezoidal slide rail 1-2.

specific Embodiment approach 3

[0036] Combine below Figure 1-10 To illustrate this embodiment, the cutting table 2 includes a flat plate 2-1, a trapezoidal slideway 2-2, a pin 2-3, a translation plate 2-4, a fastening screw II2-5 and a central axis 2-6, and the flat plate 2 The upper end of -1 is provided with a trapezoidal slideway 2-2, and the center of the lower end of the flat plate 2-1 is fixedly connected with a central shaft 2-6, and the central shaft 2-6 is inserted into the swivel seat 1-7 with clearance fit, and the fastening screw I1 -6 is placed on the central axis 2-6, and there are two translation plates 2-4 left and right, and the two translation plates 2-4 are respectively slidably connected to the left and right ends of the trapezoidal slideway 2-2, and the two translation plates 2- The upper end of 4 is provided with a plurality of pins 2-3, and the front ends of the two translation plates 2-4 are screwed with fastening screws II2-5, and the two fastening screws II2-5 are all supported on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com