Redundant control device and method for overhead travelling crane translation mechanism

A translational mechanism and redundant control technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of not being able to move, not thinking, and logistics blockage, etc., to achieve strong practicability, great economic benefits, and low investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the examples.

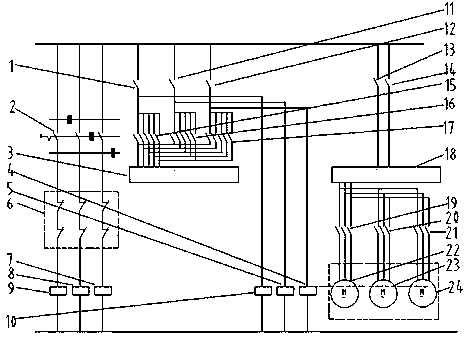

[0044] A redundant control device for a crane translation mechanism, see figure 1 , including normally open contact 1 of the normal operation relay of No. 2 cart connected to one end of the line, normally open contact 11 of the main trolley relay, normally open contact 12 of the auxiliary trolley relay, three-position switch 2, and normally open contact of the main trolley relay Point 13, auxiliary trolley relay normally open contact 14, wherein:

[0045] Normally open contact 1 of the relay for normal operation of No. 2 cart, normally open contact 11 of the main trolley relay, and normally open contact 12 of the auxiliary trolley relay are respectively connected in series with the shift contact 15 of the master command controller of the cart and the master command controller of the main trolley Gear position contact 16, auxiliary small car owner order controller gear co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com