Horizontal well injection remediation system and method for pressed and covered contaminated soil or underground water

A technology of contaminated soil and remediation system, which is applied in the field of horizontal well injection and remediation system, which can solve the problems of inability to realize continuous injection, difficulty in laying horizontal pipes, and existence of repair blind spots, so as to achieve the effect of chemical remediation, increase the range of chemical diffusion, and stabilize the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

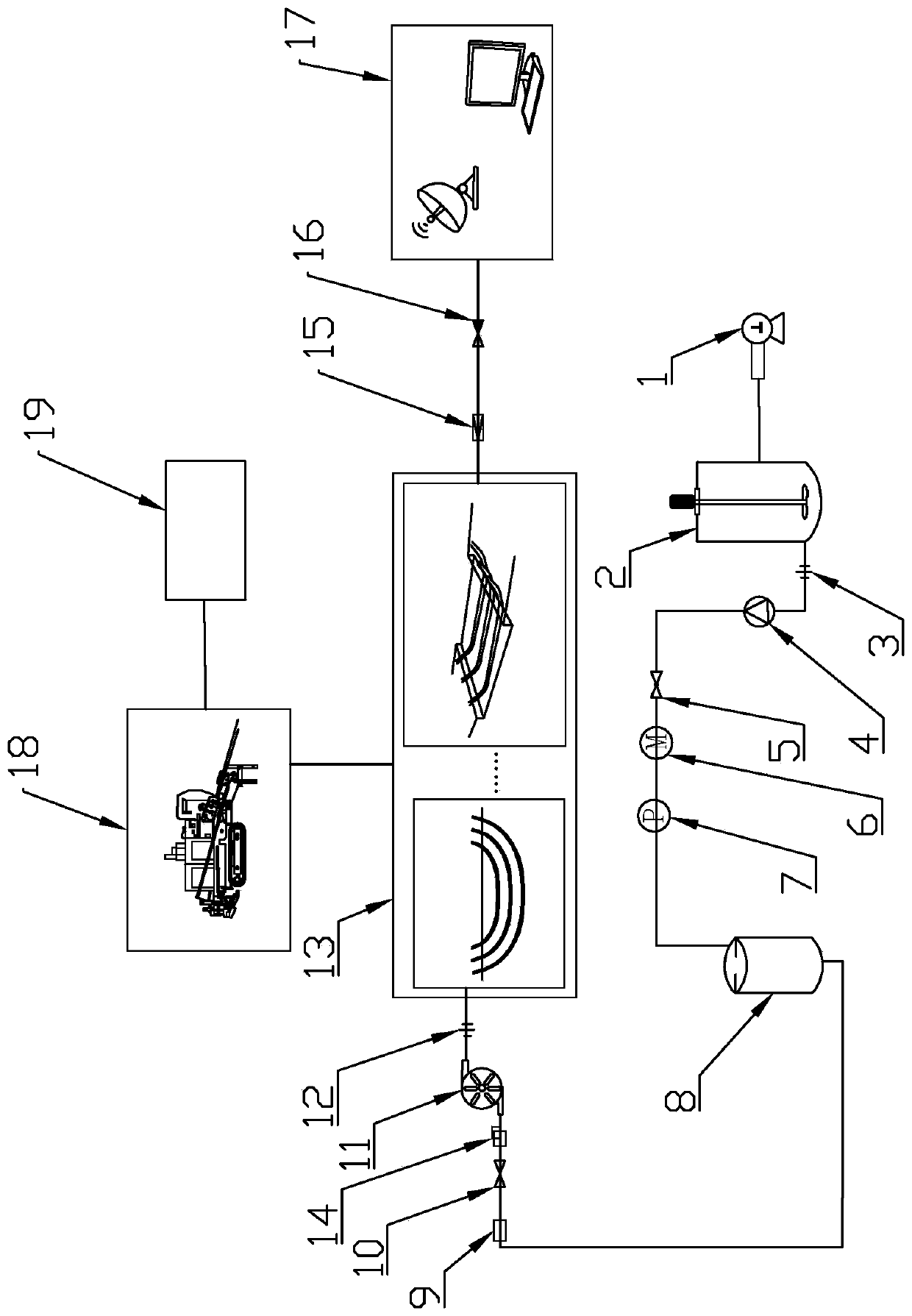

[0036] Such as figure 1 As shown, the present invention provides a horizontal well injection repair system for compressed contaminated soil or groundwater, including a well forming unit 18, a waste residue collection unit 19, a horizontal well unit 13, a medicament configuration unit, a medicament injection unit and an electronic monitoring unit;

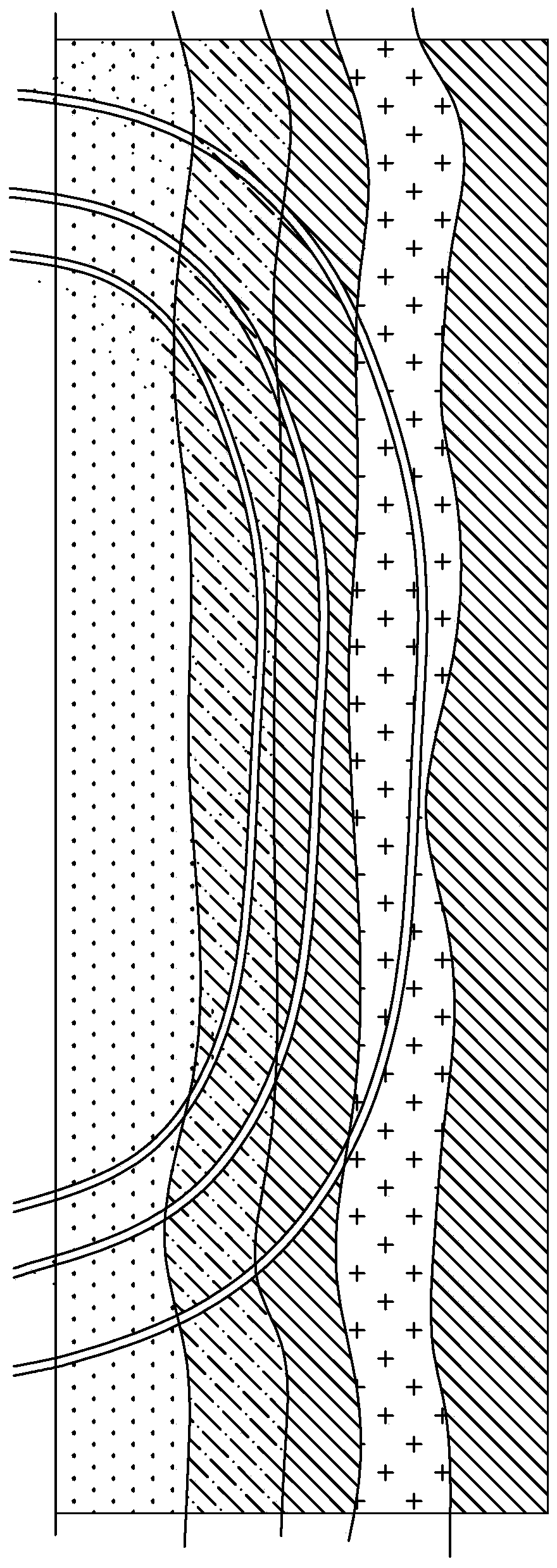

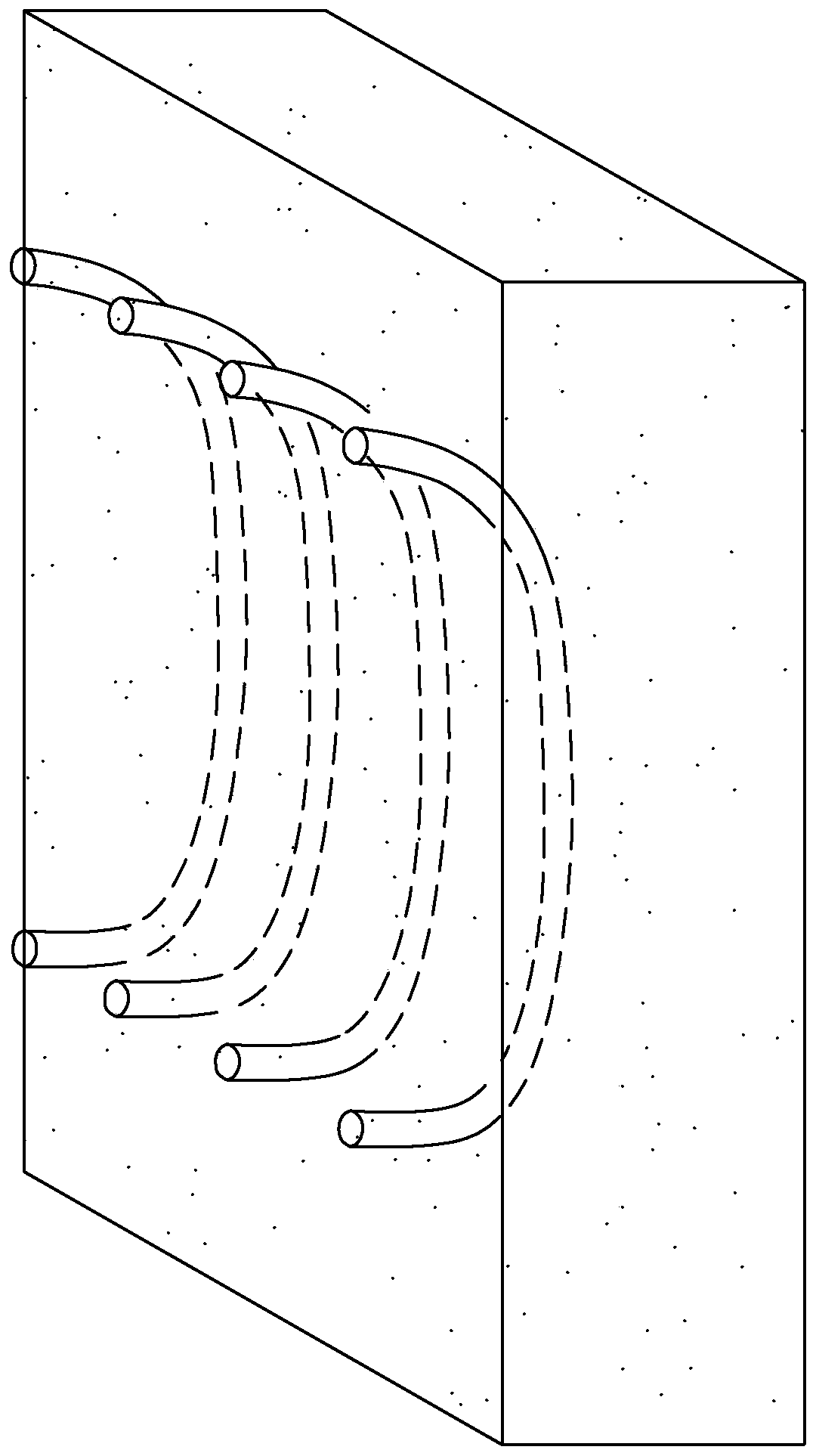

[0037] The well-forming unit 18 includes a drilling rig, a drill bit, a drill pipe, a surface guide instrument, etc., and is used to form an underground injection channel at the place where the contaminated soil or groundwater is covered; the layout of the underground injection channel can be selected according to the pollution situation of the specific polluted site The combined form of multiple underground injection channels, such as Figure 2A As shown, multiple underground injection channels are arranged along the same vertical plane with different polluted layers, such as Figure 2B As shown, a plurality of underground injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com