Terbium-containing borate compound, terbium-containing borate polycrystalline compound, optical crystal, preparation method and use thereof

A technology of optical crystals and compounds, applied in boron oxide compounds, chemical instruments and methods, borates, etc., can solve the problems of TGG crystal difficulties, crystal inclusions, serious volatilization, etc., and achieve wide transmission spectrum range, transmission Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Synthesis of Terbium-Containing Rb by High Temperature Solid State Method 2 ikB 2 o 6 Borate polycrystalline compounds:

[0066] Raw materials: Rb 2 CO 3 0.001mol, Li 2 CO 3 0.005mol, Tb 4 o 7 0.00025mol, H 3 BO 3 0.001mol, the purity of the above raw materials is analytically pure.

[0067] Steps: Weigh the above raw materials, grind them thoroughly, mix them evenly, put them in a 10ml corundum crucible, then place the corundum crucible containing the mixed raw materials in a muffle furnace, heat to 630-670°C, and grind them repeatedly to powder Shape, obtain the terbium-containing borate polycrystalline compound Rb of the present invention 2 ikB 2 o 6 .

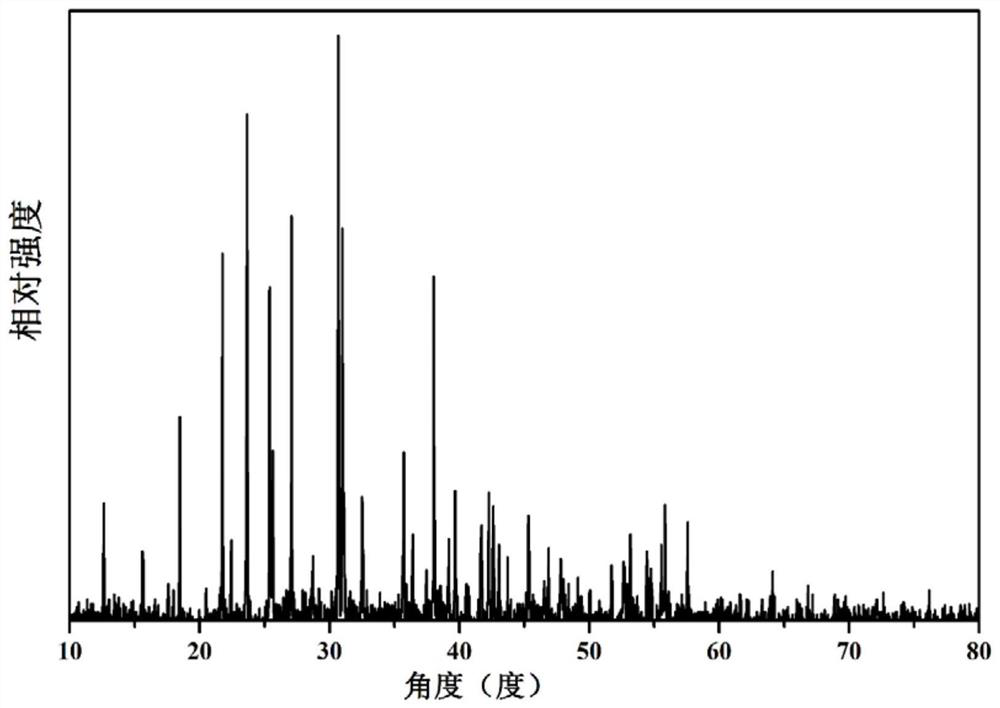

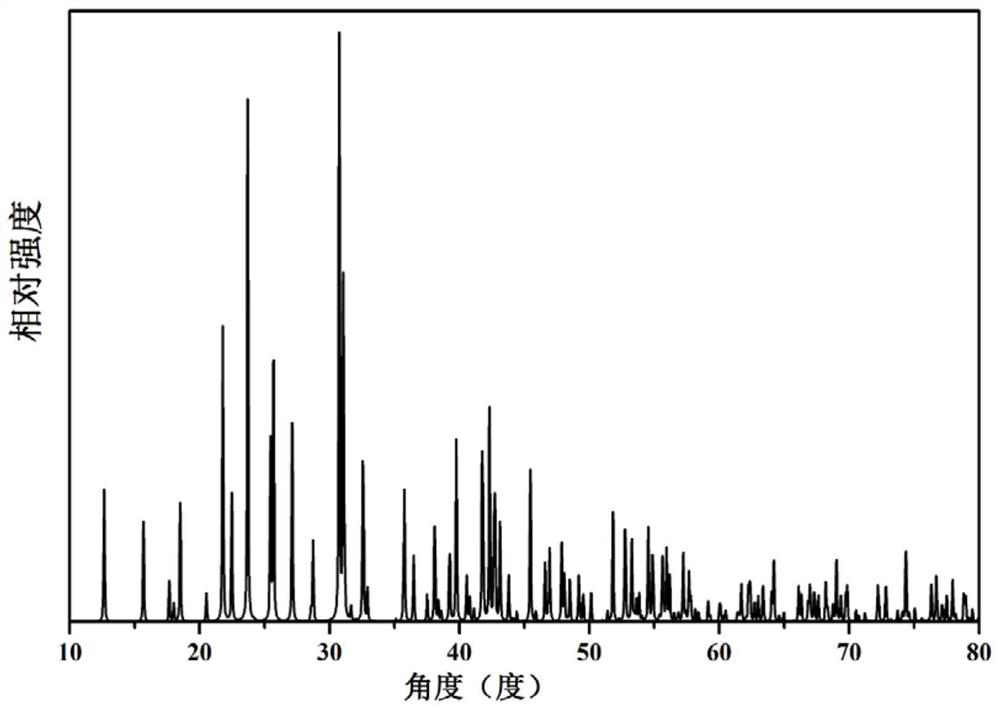

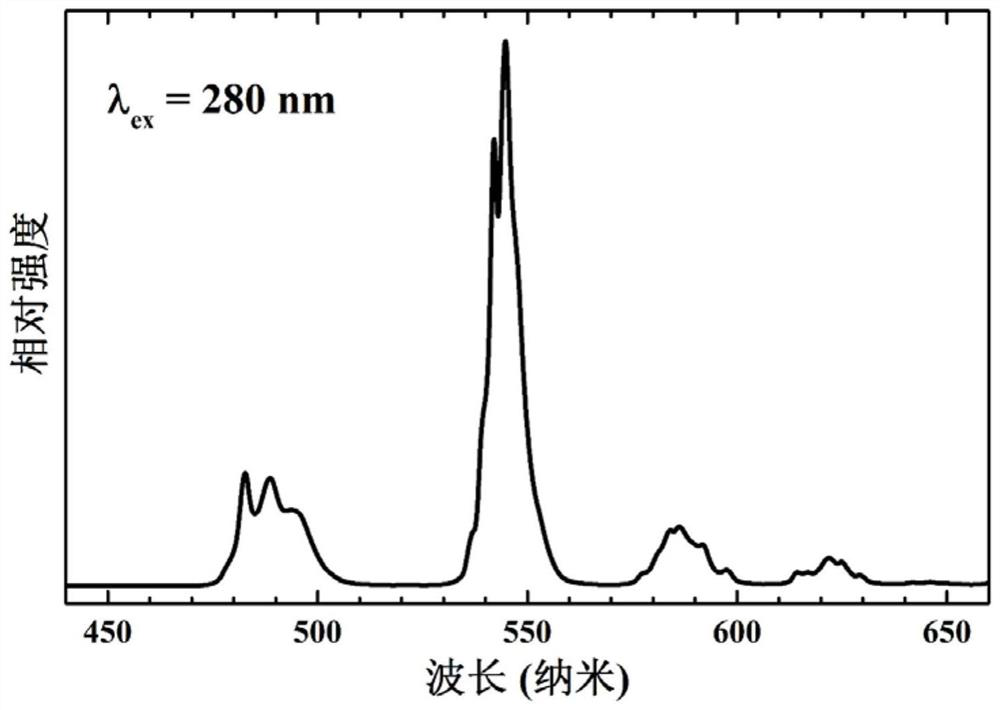

[0068] Utilize X-ray powder diffraction to the prepared Rb of embodiment 1 2 ikB 2 o 6 Phase analysis of polycrystalline powder, figure 1 is Rb 2 ikB 2 o 6 The XRD pattern of the polycrystalline compound, where the ordinate is the diffraction intensity, and the abscissa is the diffraction ang...

Embodiment 2

[0071] Growth of Borate Compound Rb Containing Terbium by Flux Method 2 ikB 2 o 6 Single crystal:

[0072] Raw materials: Rb 2 CO 3 0.23mol, Li 2 CO 3 0.15mol, Tb 4 o 7 0.025mol, H 3 BO 3 0.5mol, the purity of the above raw materials is analytically pure. The above raw materials are equivalent to Rb 2 CO 3 Rubidium element in: Li 2 CO 3 Lithium element in: Tb 4 o 7 Terbium element in: H 3 BO 3 The boric acid element in 4.6:3:1:5.

[0073] Steps: 1) Weigh the above-mentioned raw materials, grind and mix them evenly, place them in a platinum crucible, place the platinum crucible containing the mixed raw materials in a muffle furnace, and raise the temperature to 600°C at a rate of 60°C / h to obtain crystals Raw material for growth.

[0074] 2) Put the raw material for crystal growth into a platinum crucible, put it into a crystal growth furnace, heat to melt, and stir for 1-2 days. When the surface temperature of the mixed melt is 1-3°C higher than the sat...

Embodiment 3

[0077] Growth of Terbium-Containing Borate Compound Rb by Flux Pulling Method 2 ikB 2 o 6 Single crystal:

[0078] Raw materials: Rb 2 CO 3 0.23mol, Li 2 CO 3 0.15mol, Tb 4 o 7 0.025mol, H 3 BO 3 0.5mol, the purity of the above raw materials is analytically pure. The above raw materials are equivalent to Rb 2 CO 3 Rubidium element in: Li 2 CO 3 Lithium element in: Tb 4 o 7 Terbium element in: H 3 BO 3 The boric acid element in 4.6:3:1:5.

[0079] Steps: 1) Weigh the above-mentioned raw materials, grind and mix them evenly, place them in a platinum crucible, place the platinum crucible containing the mixed raw materials in a muffle furnace, and raise the temperature to 600°C at a rate of 60°C / h to obtain crystals Raw material for growth.

[0080] 2) Put the raw material for crystal growth into an iridium crucible, put it into a crystal pulling furnace, fill it with nitrogen protection, heat to melt, stir for 1-2 days, and the surface temperature of the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com