Optical Parametric Oscillator Laser Based on Wide Bandgap Semiconductor Silicon Carbide Crystal

A wide bandgap semiconductor, optical parametric oscillation technology, applied in the direction of active medium materials, etc., can solve the problems of unreported OPO lasers, SiC crystal materials have not been paid attention to, and achieve high cost performance, low cost, and easy installation and adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

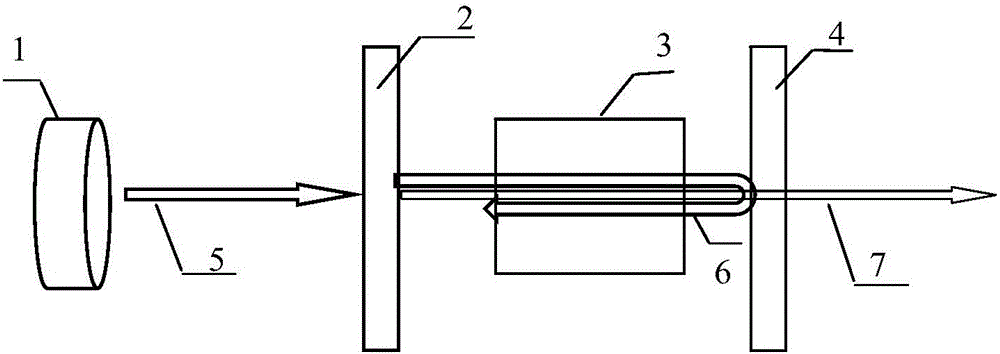

[0031] Optical parametric oscillator laser structure such as figure 1 As shown, it is composed of an excitation source 1, an input mirror 2, a semiconductor SiC crystal 3, and an output mirror 4, wherein: the excitation source 1 is Nd:YAG (neodymium-doped yttrium aluminum garnet, Nd-doped The impurity concentration is 1at.%) Q-switched laser; the input mirror 2 is a plane mirror, and its transparent surface is coated with a dielectric film with high transmission to 1.06 μm and high reflection to 1.57 μm and 3.26 μm; semiconductor SiC crystal 3 is 4H Type SiC single crystal, the angle between the direction of light transmission and the optical axis is 54.2°, the crystal length in the direction of light transmission is 30mm, the light transmission surface is polished and plated with high transmission dielectric film for 1.06μm, 1.57μm and 3.26μm; the output mirror 4 is a flat mirror , its two clear surfaces are coated with a dielectric film with a high reflection of 1.57μm and a...

Embodiment 2

[0033] As described in Example 1, the difference is that the two transparent surfaces of the output mirror 4 are coated with a dielectric film with a high reflection of 3.26 μm and a partial transmission of 1.57 μm (the transmittance is 50%), the output mirror and the output mirror The distance between them is 80mm. Increasing the excitation power can achieve 1.57μm mid-infrared OPO laser output.

Embodiment 3

[0035] As described in Example 1, the difference is that the output mirror 4 is a concave mirror with a radius of curvature of 50 mm, and the distance between the output mirrors is 80 mm. Increase the excitation power to obtain a 3.26 μm mid-infrared OPO laser output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com