Detecting device and method of frost heave stress

A stress detection and frost heave technology, applied in measuring devices, on-site foundation soil surveys, instruments, etc., can solve the problem that the quality control of infrastructure construction in permafrost areas is difficult to ensure, the frost heave stress detection of permafrost is difficult, and the construction site is difficult to detect. Due to complex geological conditions and other problems, the acquisition method is simple and direct, the installation position and direction are not limited, and the sampling points are many.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

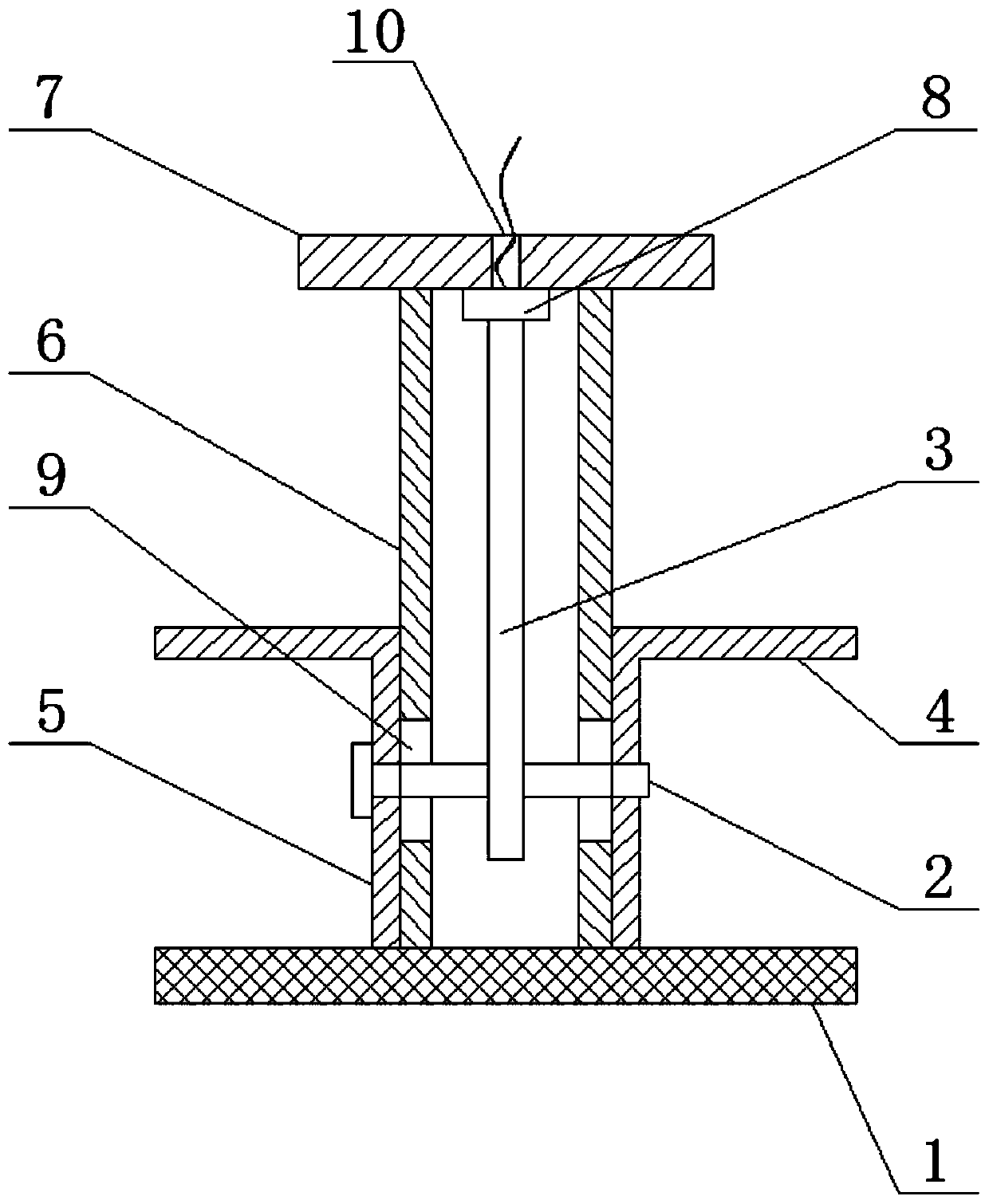

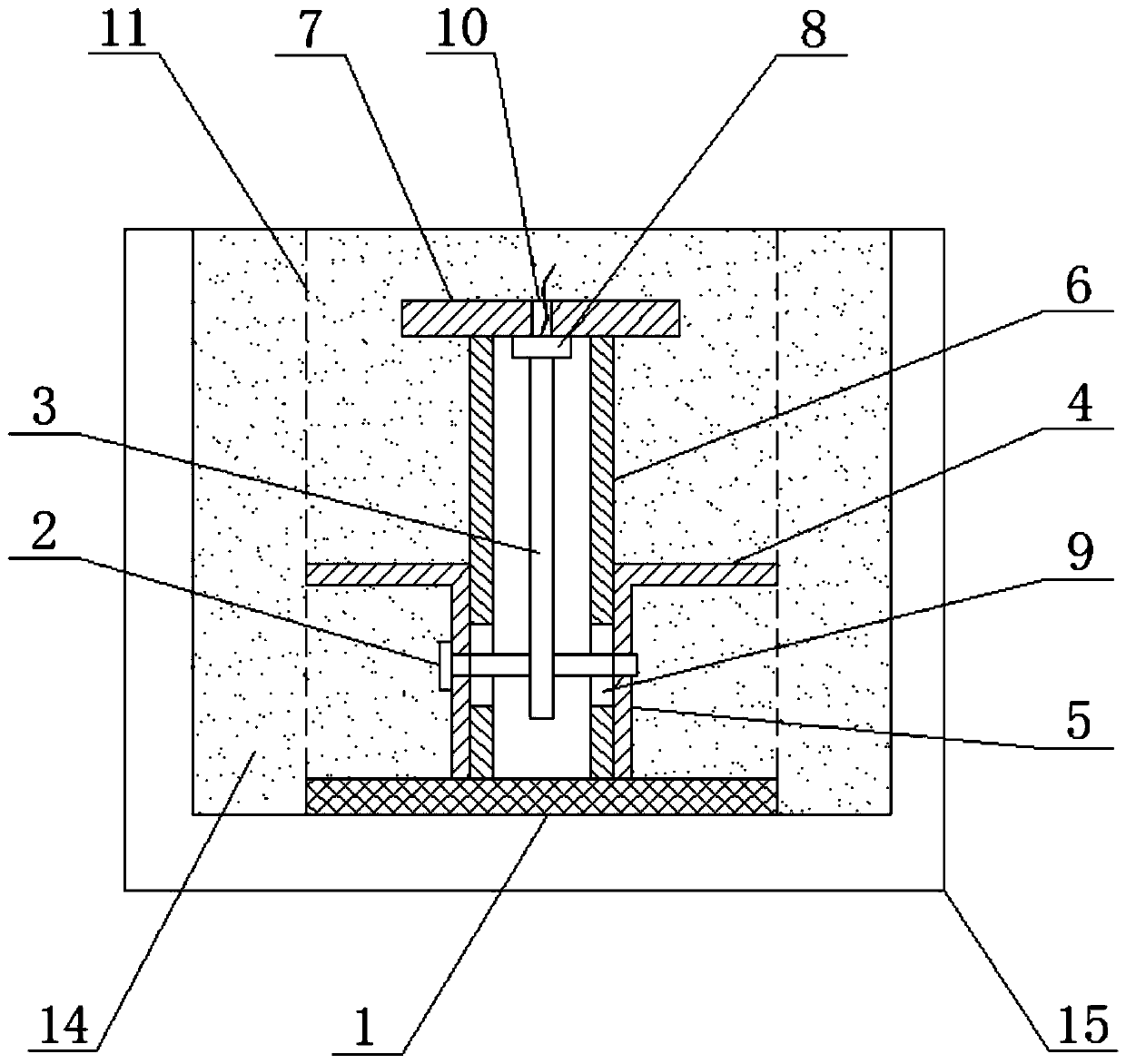

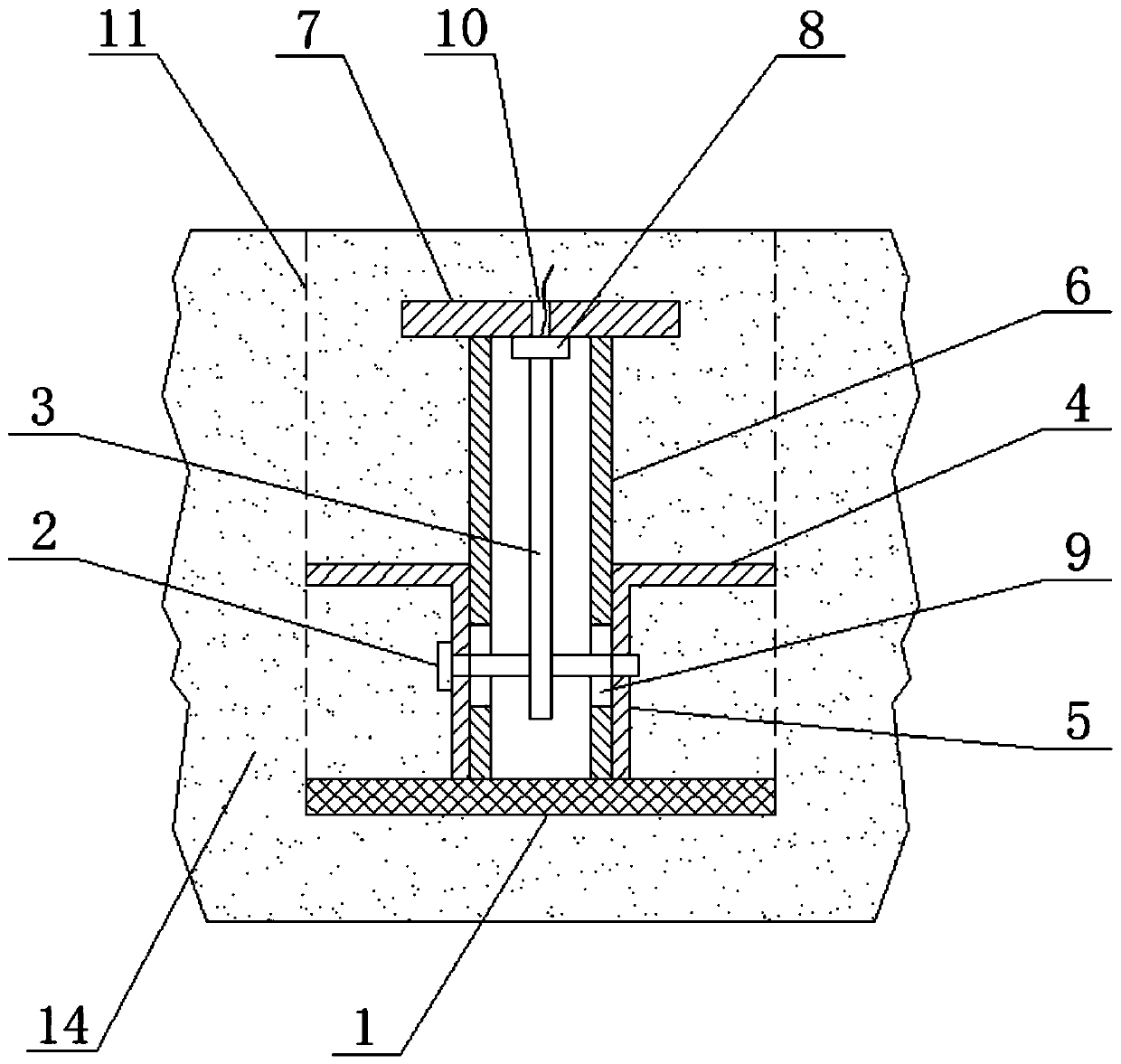

[0032] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment, this embodiment includes chassis 1, connecting rod 2, motion rod 3, anchor disc 4, sliding sleeve 5, sleeve 6, upper cover 7 and pressure sensor 8, sliding sleeve 5 is sleeved outside sleeve 6 and The two are slidingly matched, the anchor plate 4 is fixedly set outside the sliding sleeve 5, the connecting rod 2 passes through the sliding sleeve 5 and the sleeve 6 in the radial direction of the sliding sleeve 5, and the side wall of the sleeve 6 is processed with a matching connecting rod 2 The long hole 9 that moves up and down along its axial direction, the lower end of the sleeve 6 is fixedly connected to the chassis 1, the upper end of the sleeve 6 is fixedly connected with the upper cover 7, the pressure sensor 8 is located in the sleeve 6 and is arranged on the upper On the cover 7, the upper end of the moving rod 3 is set towards the measuring head of the pressu...

specific Embodiment approach 2

[0037] Specific implementation mode two: combination figure 1 , figure 2 and image 3 Describe this implementation mode, this implementation mode includes the following content:

[0038] According to the type of frozen soil in the test area, determine the number of measuring points in the test area and the distribution position of each measuring point, and determine the number of installed frost heave stress detection devices and the location of each frost heave stress detection device according to the distribution of each measurement point The frost heaving stress data of the frost heaving layer where each measuring point is located is obtained by detecting the frost heaving stress detection device, and the overall situation of the frost heaving stress in the test area is obtained according to the frost heaving stress data fed back by each measuring point.

[0039] According to the geological survey report, the test area is divided. The division principle is based on the n...

specific Embodiment approach 3

[0047] Specific implementation mode three: this implementation mode is a further limitation of specific implementation mode one or two, the frost heaving sensitive permafrost area is the concentration area of measuring points in the test area, and the corresponding number is selected according to the number of measuring points in the frost heaving sensitive permafrost area The frost heaving stress detection device, the present invention combined with the prototype to carry out multiple tests according to the geological survey situation, in the frost heaving sensitive permafrost area plane horizontal and vertical intervals of 50cm ~ 100cm arrangement of measuring points is the best setting range, according to the unit per square meter Set 1 to 4 measuring points in the area, and arrange the measuring points at a horizontal and vertical interval of 200cm to 400cm in the plane of the frost heave non-sensitive area, which can be set according to 1 to 4 measuring points in a unit a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com