Post-tensioned bonded co-tensioned prestressed concrete composite beam and design and construction method thereof

A technology of bonding prestressed concrete, applied in the direction of joists, girders, trusses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

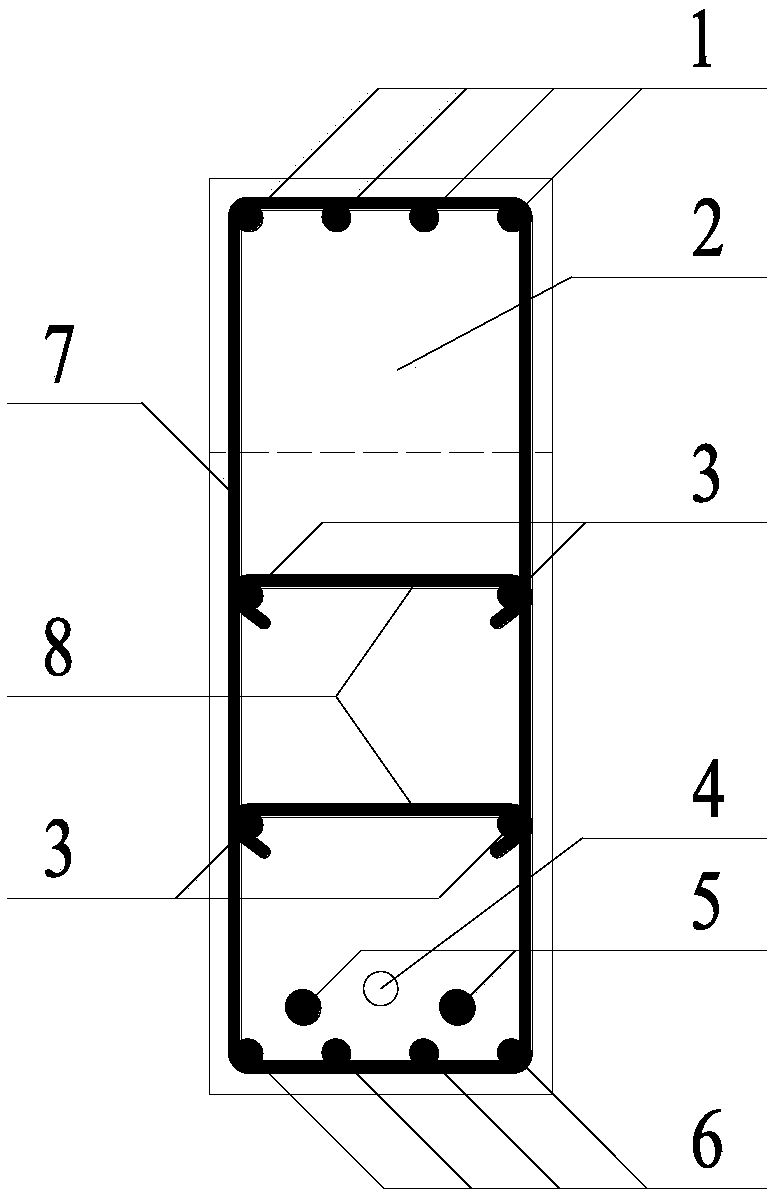

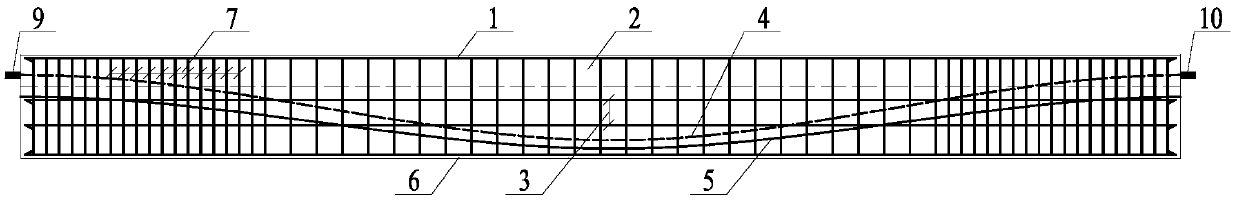

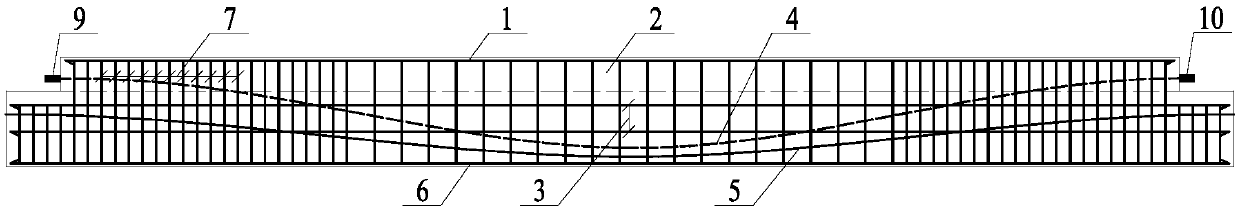

[0055] see figure 1 — Figure 4A post-tensioned co-tensioned prestressed concrete composite beam with bonding, the composite beam is applied with bonding and bonding prestress to the composite beam by using pre-tensioning method and post-tensioning method, in the composite beam A layer of top longitudinal reinforcement 1 is provided on the top of the composite beam, a layer of bottom longitudinal reinforcement 6 is provided at the bottom of the composite beam, and a composite layer 2 is provided on the top of the composite beam. The middle part is provided with two layers of tie bars 8, and waist bars 3 are arranged at the lower end of each layer of tie bars 8, and several pre-tensioned prestressed tendons 5 are arranged at the bottom of the composite beam. The lower part is provided with several bonded prestressed tendons 4, or arranged between the pre-ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com