Rotary blade meshing pump core and rotary blade meshing pump

A meshing and pump core technology, which is applied in the field of rotary vane meshing pump core and rotary vane meshing pump, can solve the problems of high operation and maintenance cost, high time cost, and difficult to predict the cost of time cost, etc., to improve flow rate and head, Effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The rotary vane meshing pump core and the rotary vane meshing pump of the present invention will be further described below with reference to the drawings and specific embodiments.

[0042] In the following specific embodiments, the water inlet direction is the front and the water outlet direction is the back.

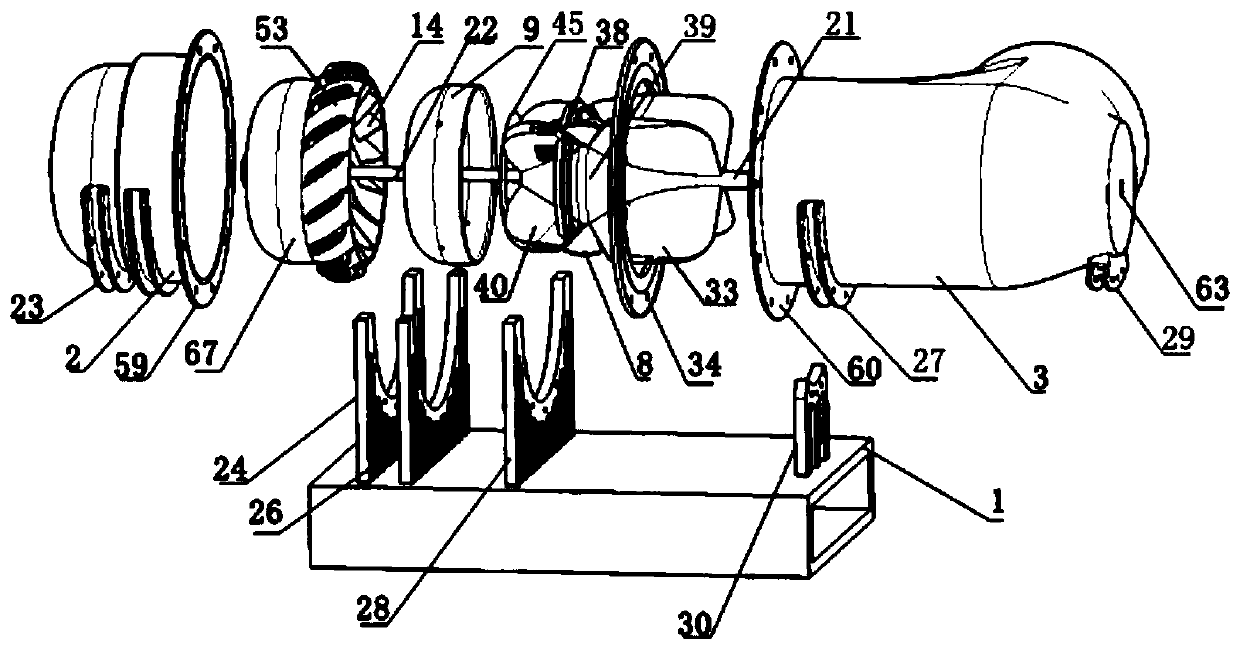

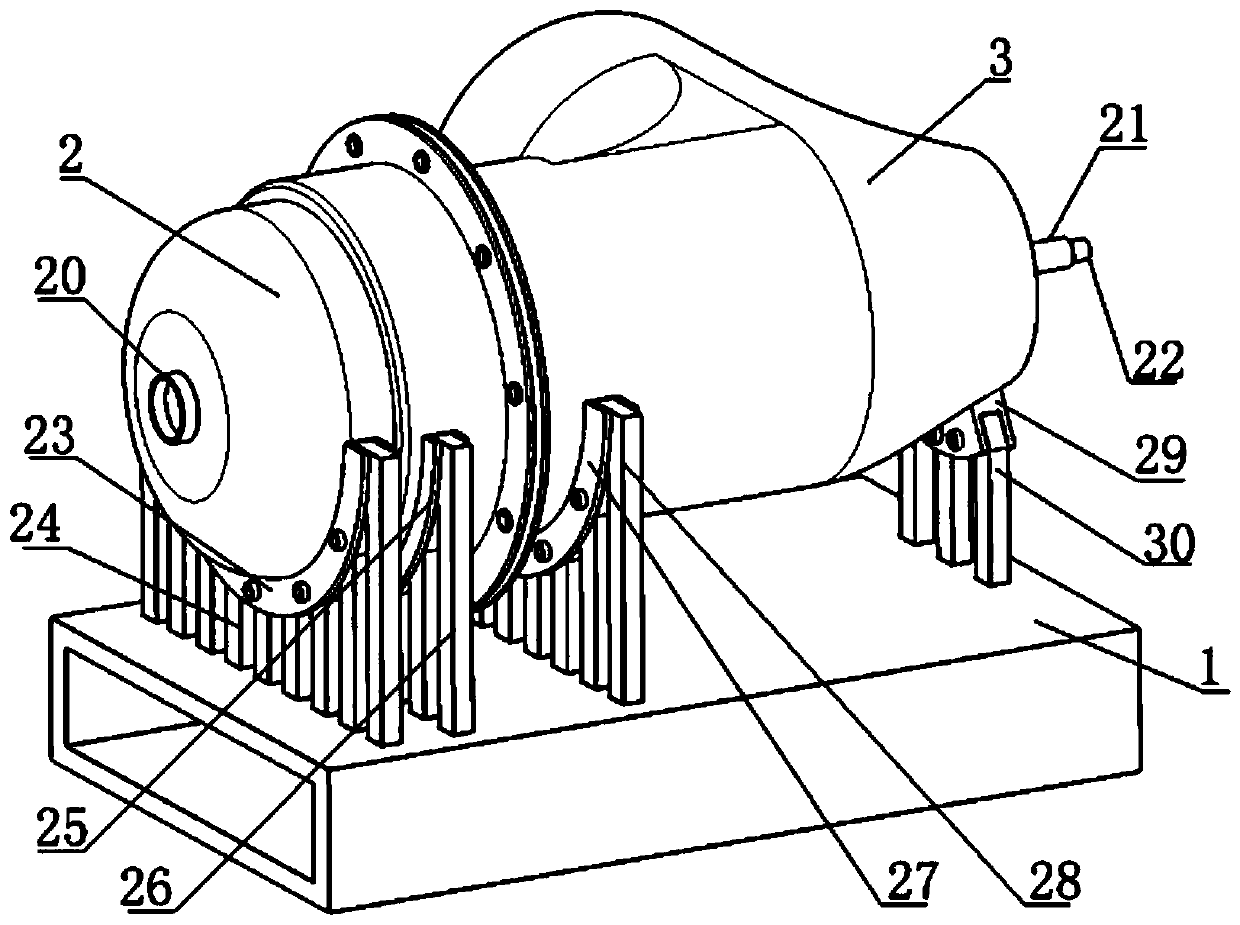

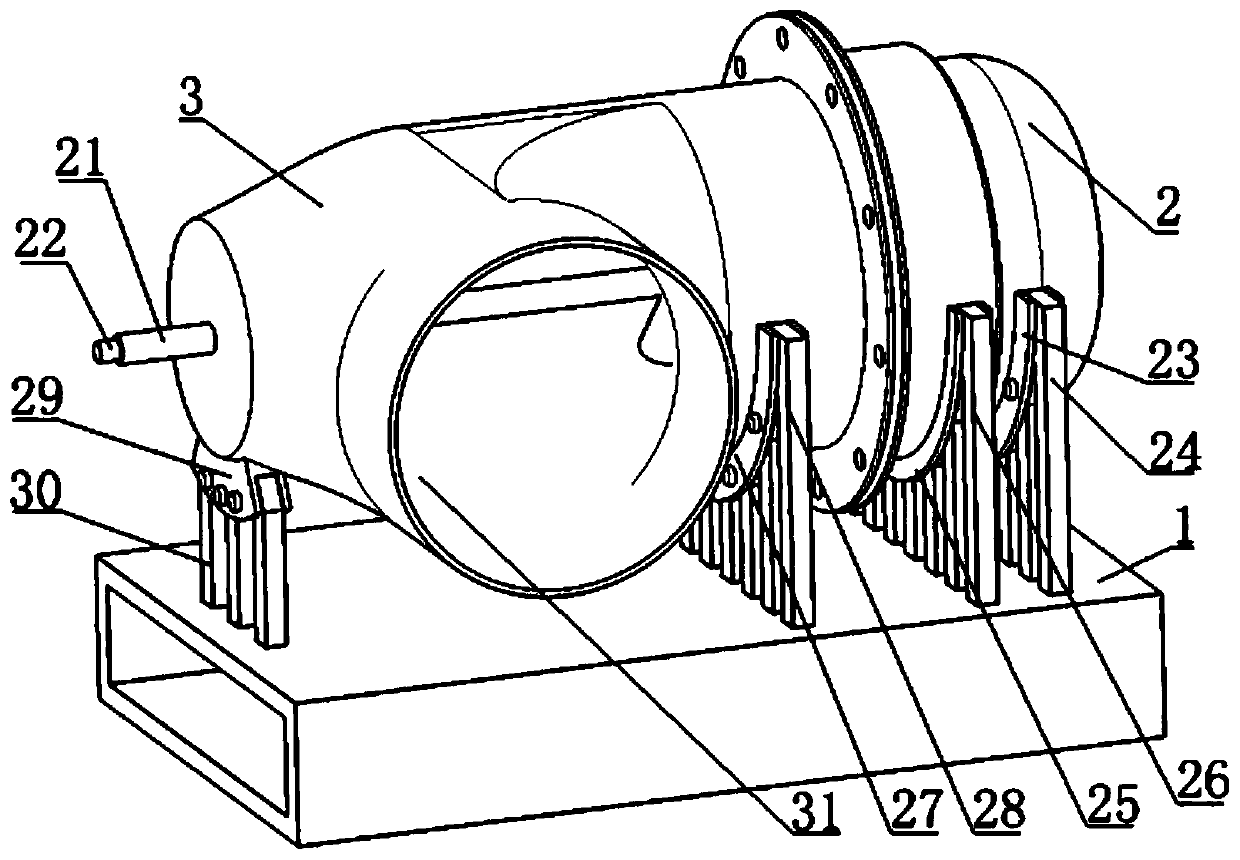

[0043] Such as figure 1 , Figure 4 , Figure 5 , Image 6 , Picture 12 , Figure 15 , Figure 16 , Figure 20 , Figure 21 As shown, a rotary vane engagement pump core includes an intermediate stabilizer, a rotating member and a rotary vane 14; the intermediate stabilizer includes a guide cone 39 and a supporting plate 40; the guide cone 39 is axially provided with a through shaft hole 32; The supporting plate 40 is radially arranged on the side wall of the front section of the guide cone 39 and there are three or more; the rear of the supporting plate 40 and the side wall of the guide cone 39 corresponding to the position of the supporting plate 40 are radially pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com