Novel structure of free space optical fiber coupling system

A fiber-optic coupling and free-space technology, applied in the field of optical fibers, can solve the problems of optical coupling efficiency decline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings.

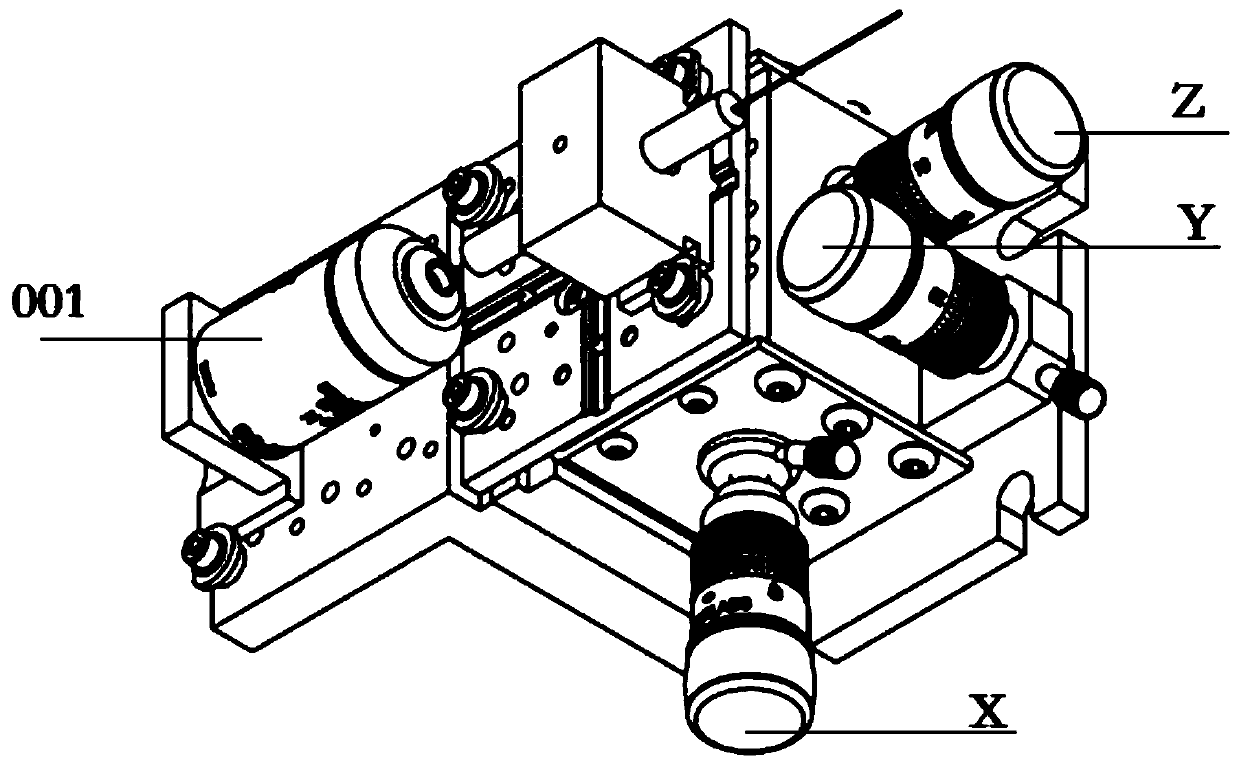

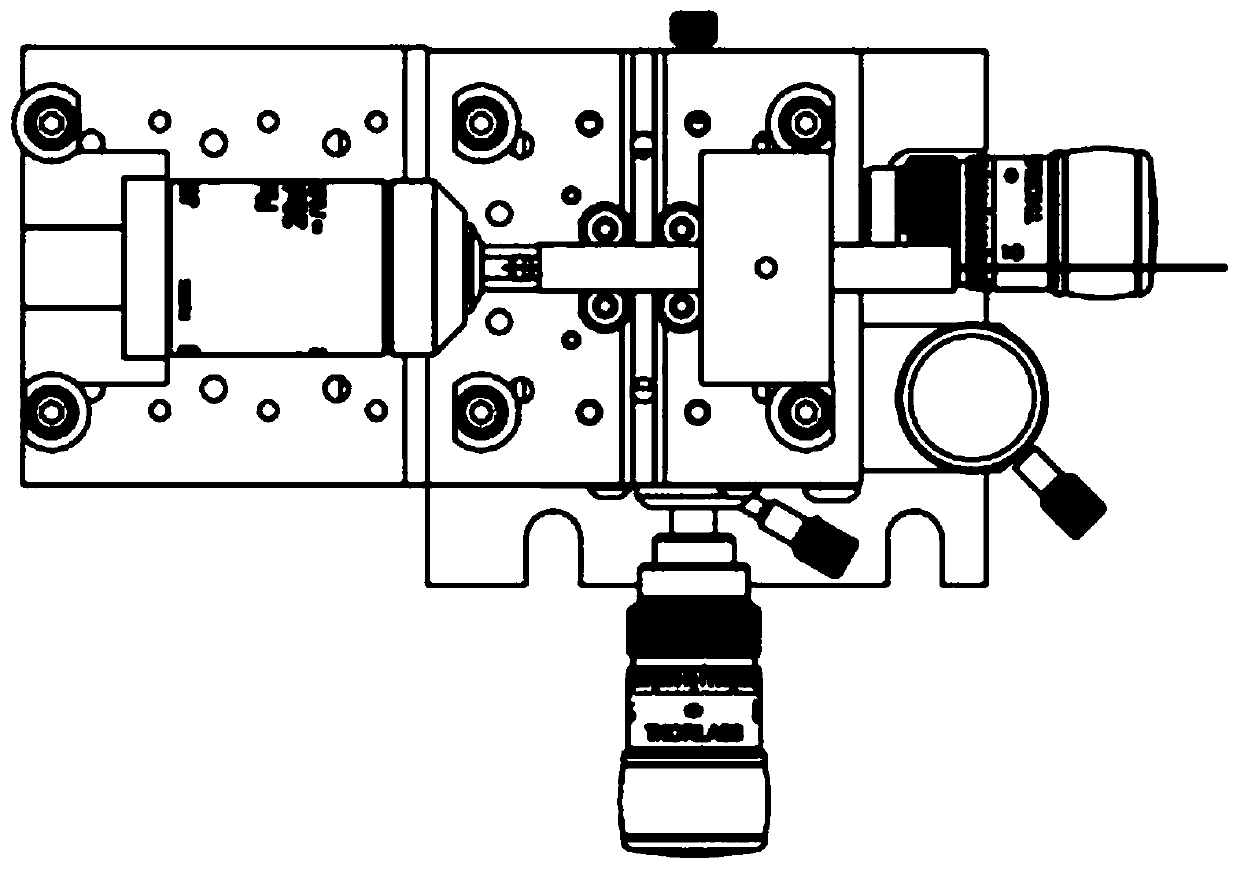

[0021] The system module structure of the present invention is a new pseudo five-dimensional free space optical fiber coupling module (hereinafter referred to as the new three-dimensional because there are only three adjustable components), and it is called a module because it has a wider range of applications and is more portable Strong, the design concepts and ideas are completely different from the traditional free space fiber coupling system new architecture module design ideas, and the adopted structure is also different from the existing free space fiber coupling structure on the market. The new three-dimensional stable free space optical fiber coupling system new architecture is based on the experimental test of the influence of the gravitational dimension and the rotation of the earth on the horizontal dimension on the coupling stability. In order to eliminate the influence of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com