A kind of rapid feeding device and feeding method for tube base for semiconductor laser

A technology of lasers and semiconductors, which is applied in the direction of semiconductor lasers, semiconductor/solid-state device manufacturing, lasers, etc., can solve the problems of complex production and manufacturing of mold bar pushers, inability to ensure uniform speed of dismantling, large thrust disturbances, etc., to achieve production Low cost, manpower saving and time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

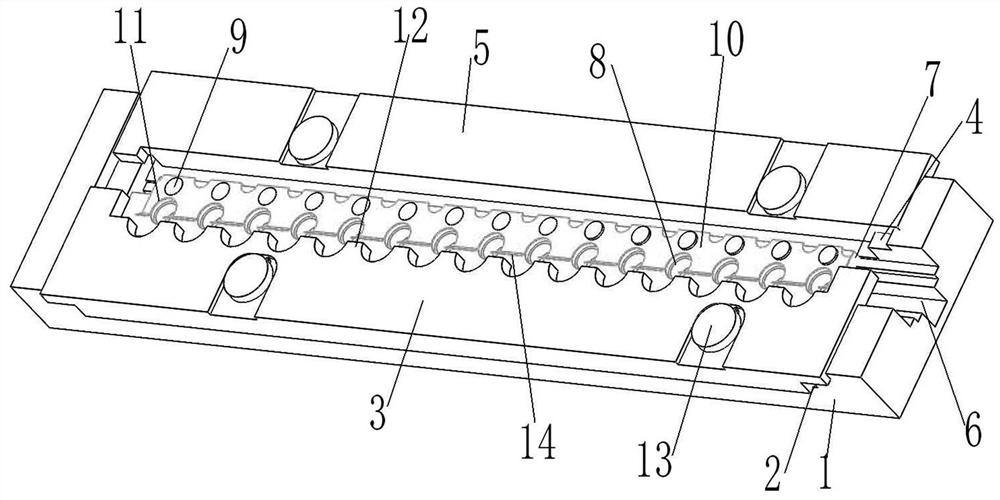

[0033] The sliding mechanism has the following structure, which includes a number of guide columns I 9 fixed on the base 1, and a number of slide slots corresponding to the guide columns I 9 are arranged on the shrapnel 10, and each guide column I 9 is slidably inserted into the corresponding slide in the slot. The shrapnel 10 slides up and down with the guide column I 9 as the positioning using the chute.

Embodiment 2

[0035] The shrapnel driving mechanism has the following structure, which includes a slide rail I 2 longitudinally arranged at the lower end of the base 1, a slide rail II 4 longitudinally arranged at the upper end of the base 1, a sliding plate 3 slidingly installed in the slide rail I 2 and a sliding installation On the upper slide plate 5 in the slide rail II 4. The lower slide 3 slides up and down relative to the base 1 through the slide rail I 2 , and the upper slide 5 slides up and down relative to the base 1 through the slide rail II 4 .

Embodiment 3

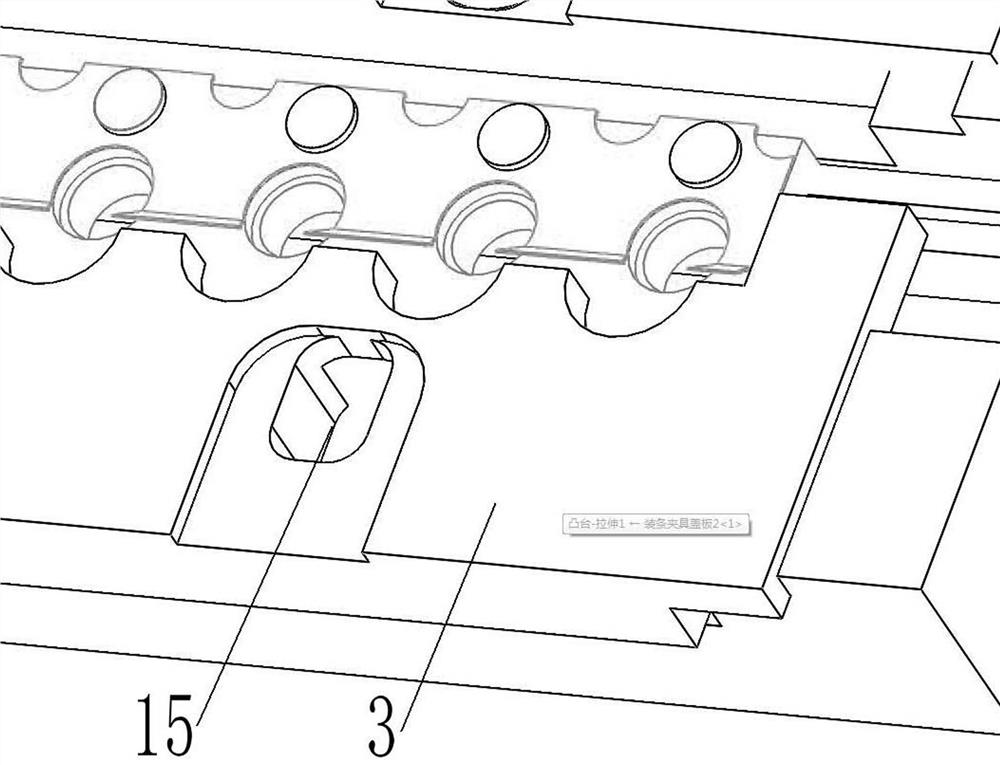

[0037] It also includes a long hole 15 arranged longitudinally on the lower plate 3, and the guide column II 13 is fixed on the base 1 after passing through the long hole 15. The lower plate 3 slides up and down through the long hole 15 with the guide column II 13 as the positioning, so that the lower plate 3 can only slide up and down along the slide rail I2 without deviation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com