Boning device and technology for chicken feet

A technology of chicken feet and equipment, which is applied in the field of chicken feet deboning equipment and chicken feet deboning technology, can solve the problems of chicken feet skin fragmentation, large safety hazards, and low production efficiency, and achieve easy bone removal, efficient separation, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

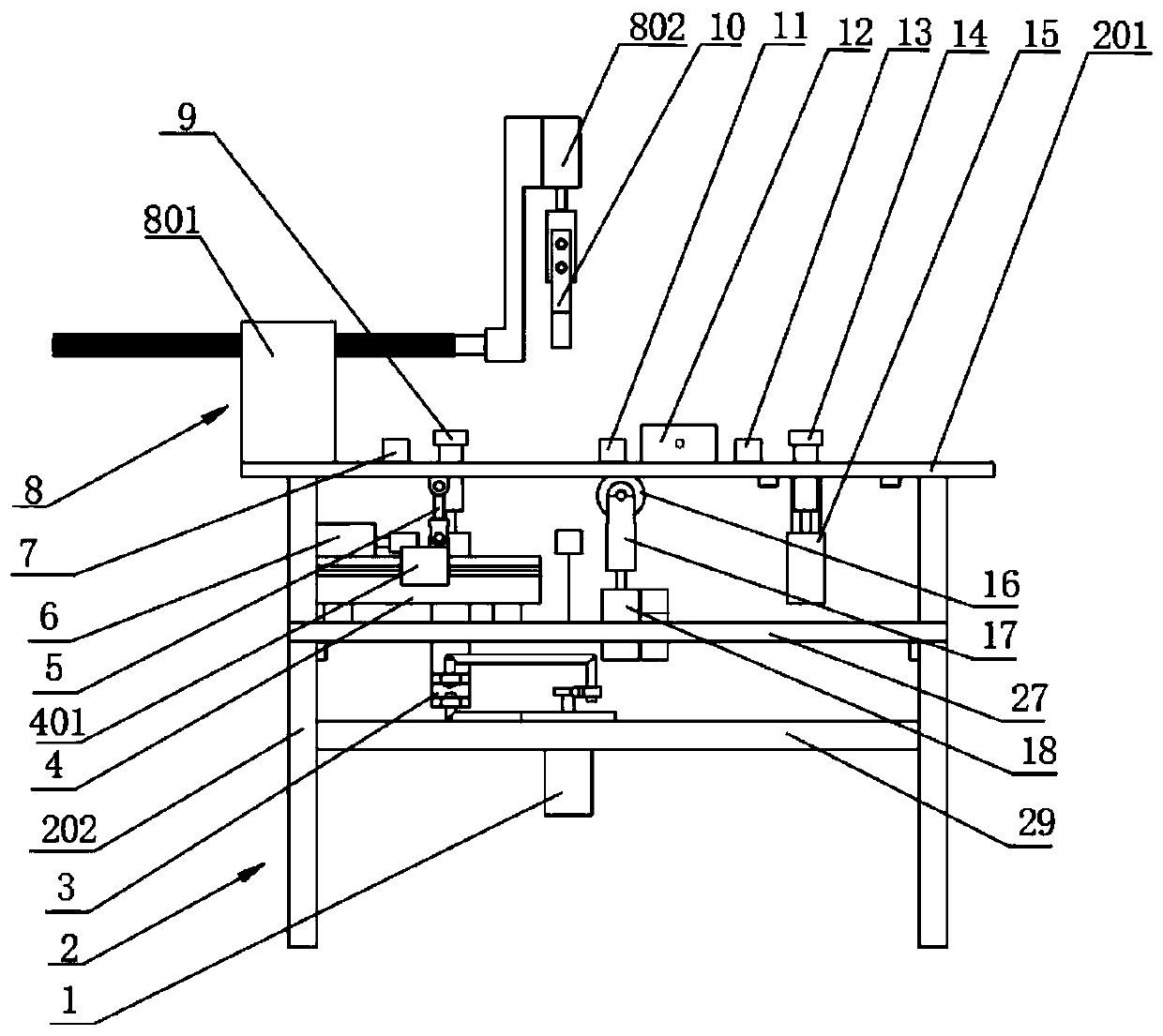

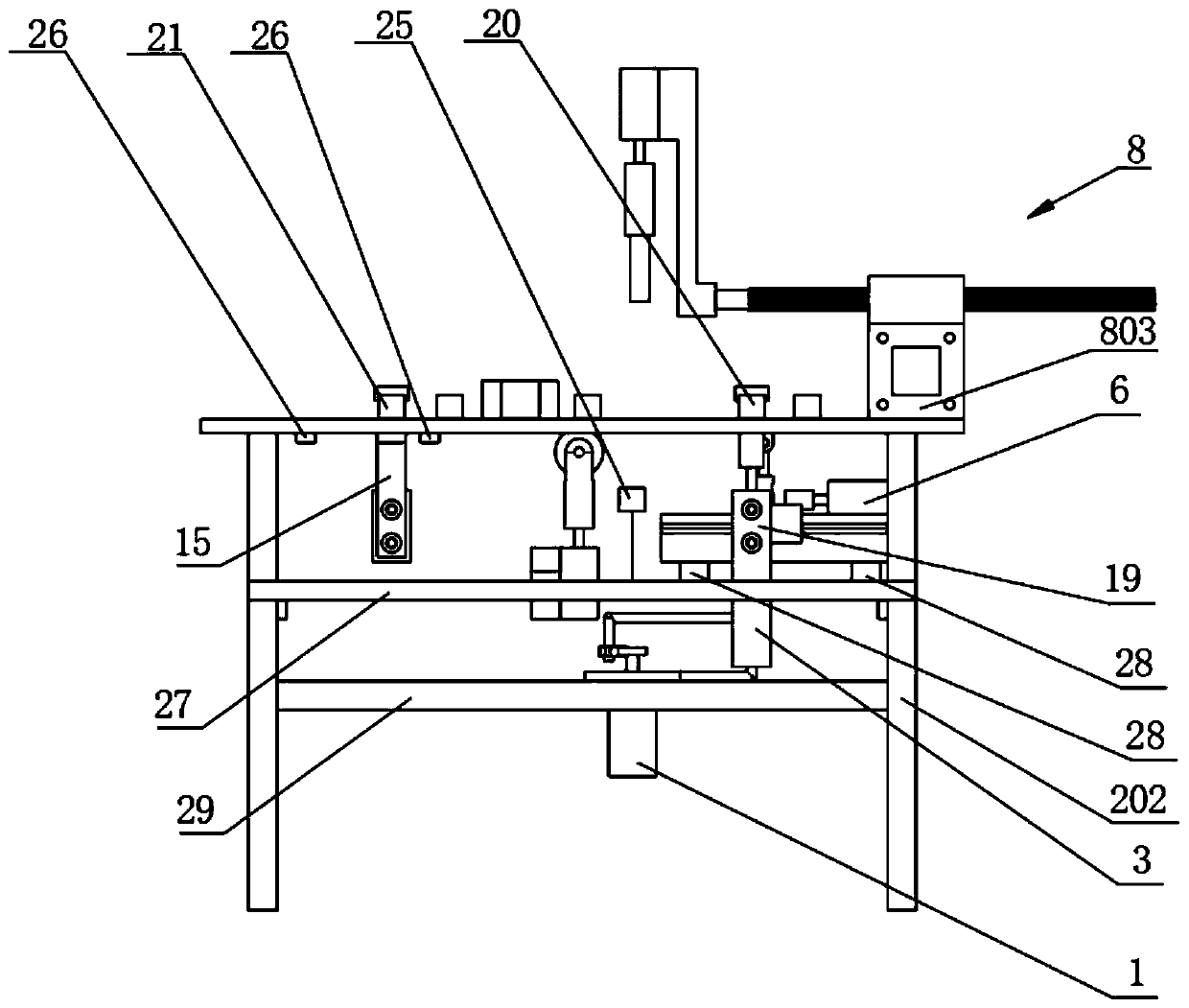

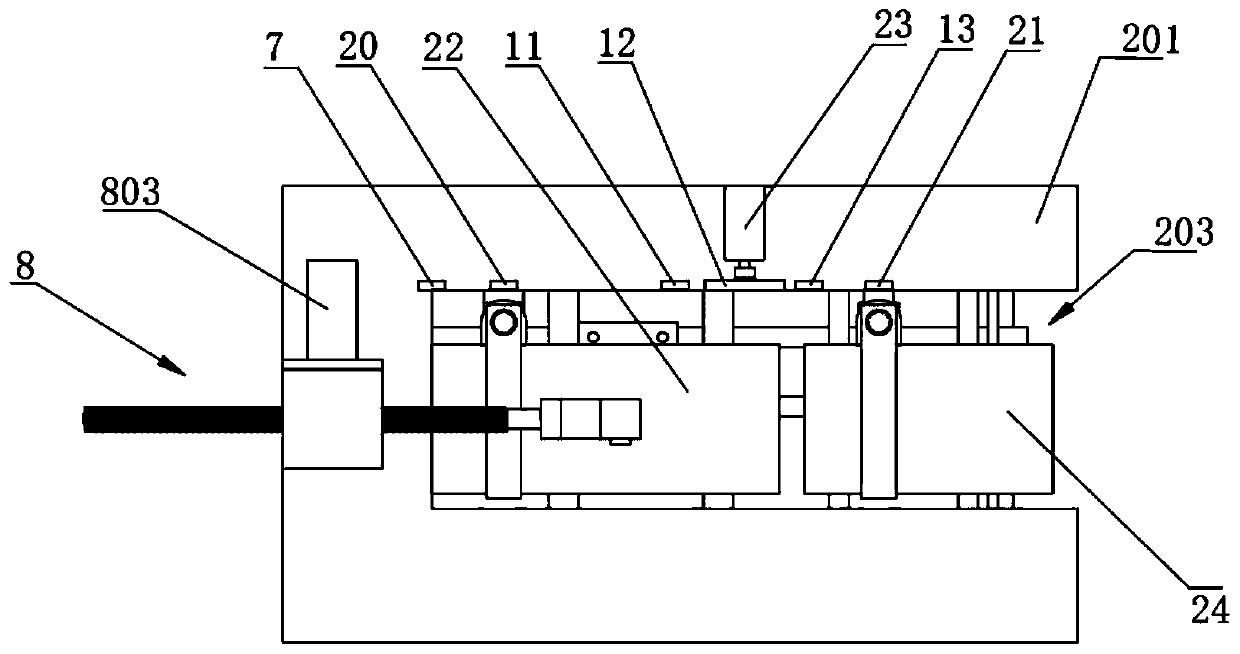

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0036] like Figure 1-9 A chicken paw deboning equipment as shown includes a frame 2, the frame 2 includes a table top 201 and a support column 202, an opening groove 203 is provided on the table top 201, and a cutting tool propulsion device 8 and a push plate in a vertical direction are fixed on the table top 201 Cylinder 23, tool propulsion device 8 includes screw mechanism 801 for controlling the lateral position of cutter 10 and the fifth cylinder 802 for controlling the vertical position of cutter 10, and one side of screw mechanism 801 is connected to be used for controlling its stepping distance The sixth motor 803 and the tool 10 are affixed to the bottom of the fifth cylinder 802 ;

[0037] Two first fixed strips 26 are fixed near the notch at the bottom surface of the opening groove 203, and the fixed plate 24 is fixed on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com