Purification method and device for full-oil-quantity oil of refueling device

A refueling device and oil technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of shortening the preparation time for refueling, low purification efficiency, incomplete filtration, etc., to avoid dilution and pollutants Precipitation, increase the number of times and years of use, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

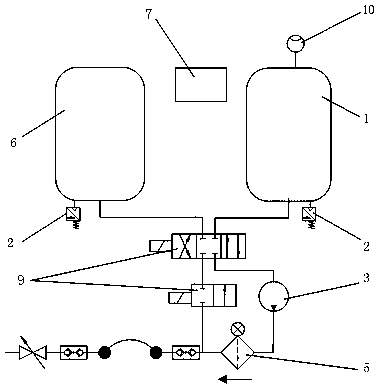

[0038] As the most basic embodiment of the present invention, such as figure 1 As shown, a purifying device for the full oil volume of a refueling device includes a main oil tank 1 and an auxiliary oil tank 6 for containing oil, and the bottoms of the main oil tank 1 and the auxiliary oil tank 6 are provided with oil outlets, connected with The pipeline connects the oil outlet of the main oil tank 1, the control valve 9, the one-way valve, the filter 5 and the outlet of the auxiliary oil tank 6. Preferably, the control valve 9 adopts a three-position four-way reversing valve and a two-position two-way valve, and the three-position four-way reversing valve is respectively connected with the oil in the main oil tank 1 and the auxiliary oil tank 6 The outlet is connected, and the two-position two-way valve is connected in series with the filter 5 on the same pipeline.

[0039] The purification device uses an oil pump 3 as a power mechanism to drive the oil to move between the ma...

Embodiment 2

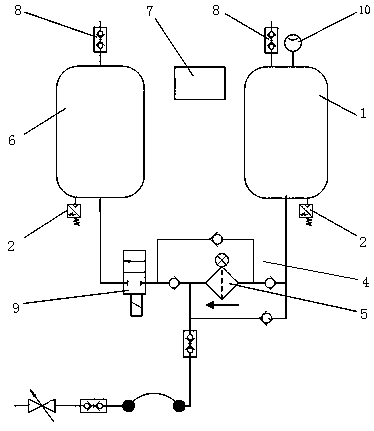

[0053] As a preferred embodiment of the present invention, such as figure 2 As shown, the oil outlets of the main oil tank 1 and the auxiliary oil tank 6 are provided at the bottom, and the oil outlet of the main oil tank 1, the control valve 9, the filter 5 and the oil outlet of the auxiliary oil tank 6 are connected by connecting pipelines. A liquid level switch 2 is arranged at the bottom of the main oil tank 1 and the auxiliary oil tank 6, and a liquid level gauge 10 is arranged in the main oil tank 1. The controller 7 collects signals such as the liquid level gauge 10 and the liquid level switch 2. The main oil tank 1 and the auxiliary oil tank 6 are charged / released from the outside through the inflation / deflation nozzle 8, and the inflation / deflation nozzle 8 and the control valve 9 are all controlled by the controller 7.

[0054] In this embodiment, the capacity of the main fuel tank 1 / auxiliary fuel tank 6 is designed according to the requirement of refueling quanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com