Building rubbish crushing and separating device

A separation device and construction waste technology, which is applied in grain processing, etc., can solve the problems of poor metal separation efficiency, reduced utilization rate of construction waste, incomplete waste screening and separation, etc., and achieve the effect of increasing the contact distance and filtering thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

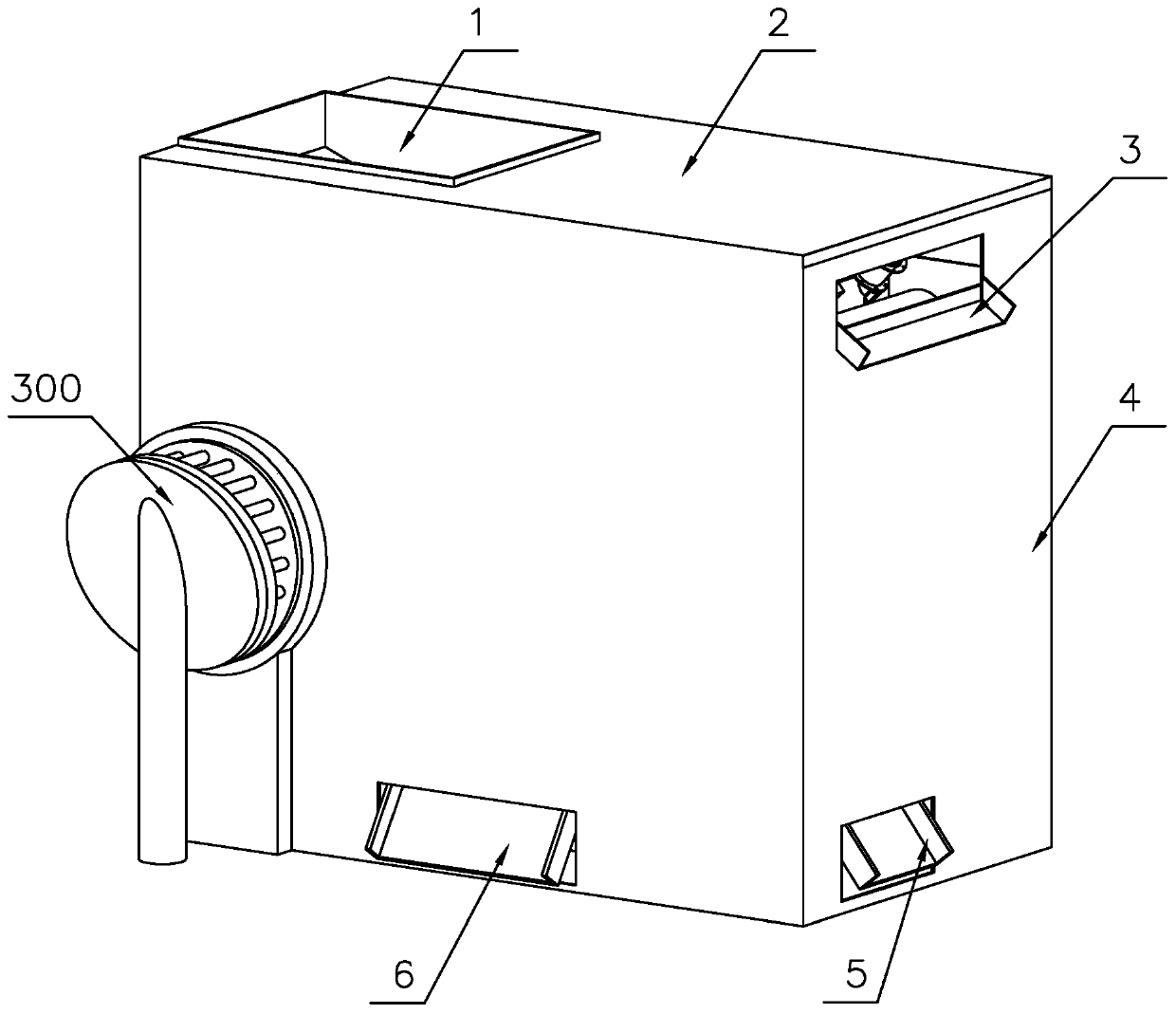

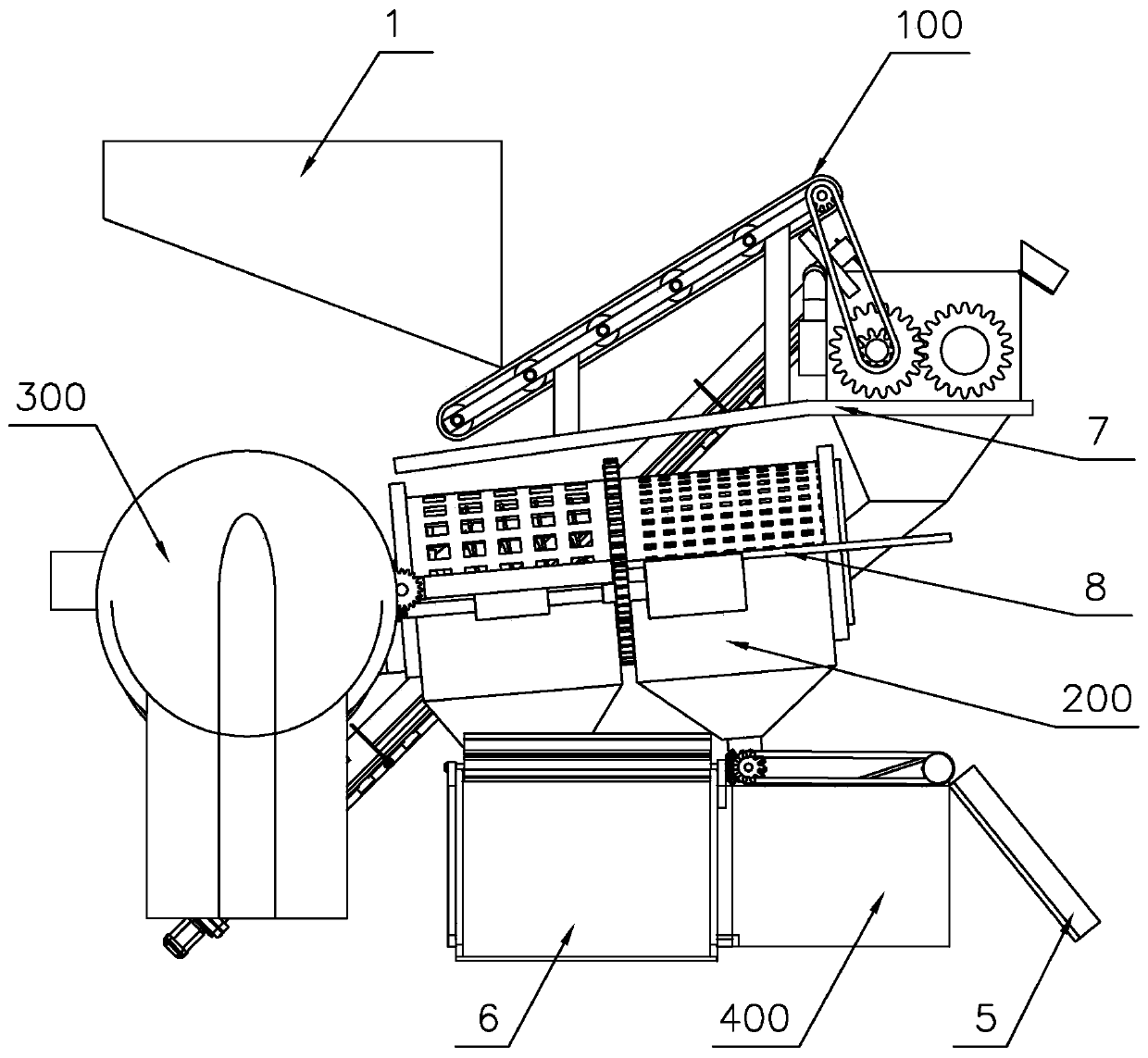

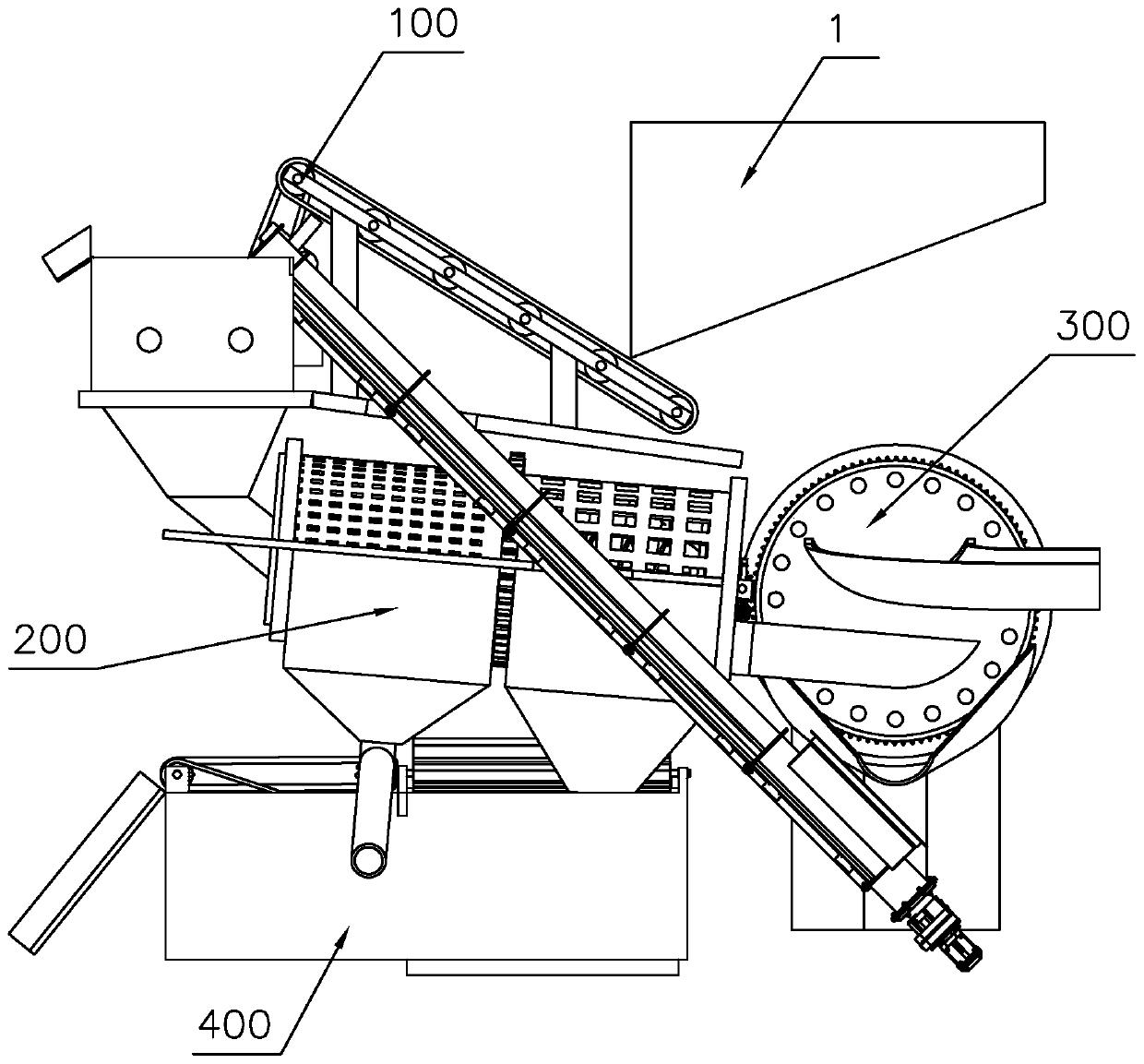

[0025] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-11 , to further specifically describe the technical solution of the present invention.

[0026]A crushing and separating device for construction waste, including a box body 4, a feeding hopper 1, a crushing device 100, a filtering device 200, and a separation device I300. The upper part of the box body 4 is provided with a top cover 2, and one side of the top cover 2 is provided with a feeding hopper 1. A crushing device 100 is provided on one side of the feed hopper 1, and a filter device 200 is provided at the lower part of the crushing device 100. The filter device 200 includes a motor II 205, a screen I 202, a screen II 204, and a spiral plate 220. One side of the crushing device 100 is provided with Screen II 204, screen I 202 is provided on one side of screen II 204, the screen I 202 and screen II 204 are connected by ring gear I 203, the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com