Clamp and robot applicable to clamp

A clamp and splint technology, applied in the field of clamps and their applicable robots, can solve the problems of being easily stuck, the splint is not stable, and the device is easy to fall, so as to prevent the device from falling, reduce manual labor, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate those skilled in the art to understand the present invention, and does not constitute a limitation to the present invention.

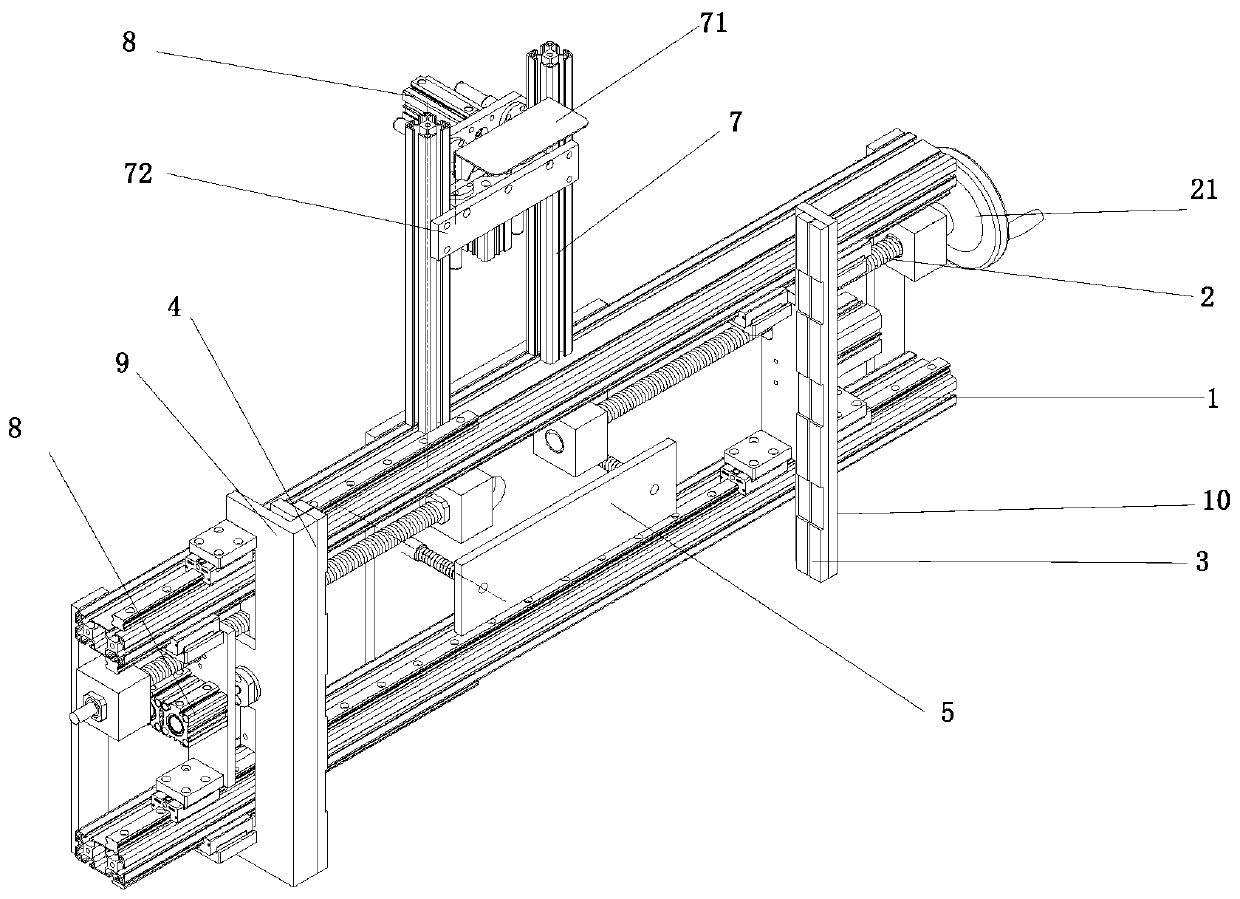

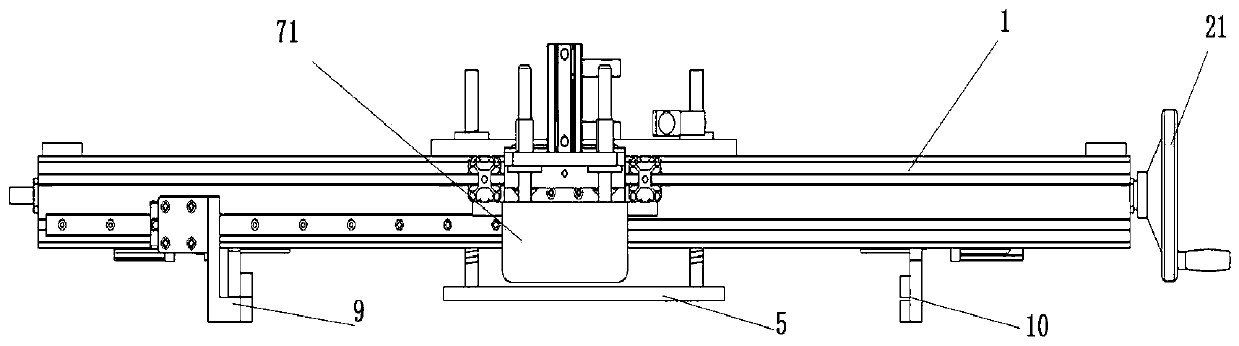

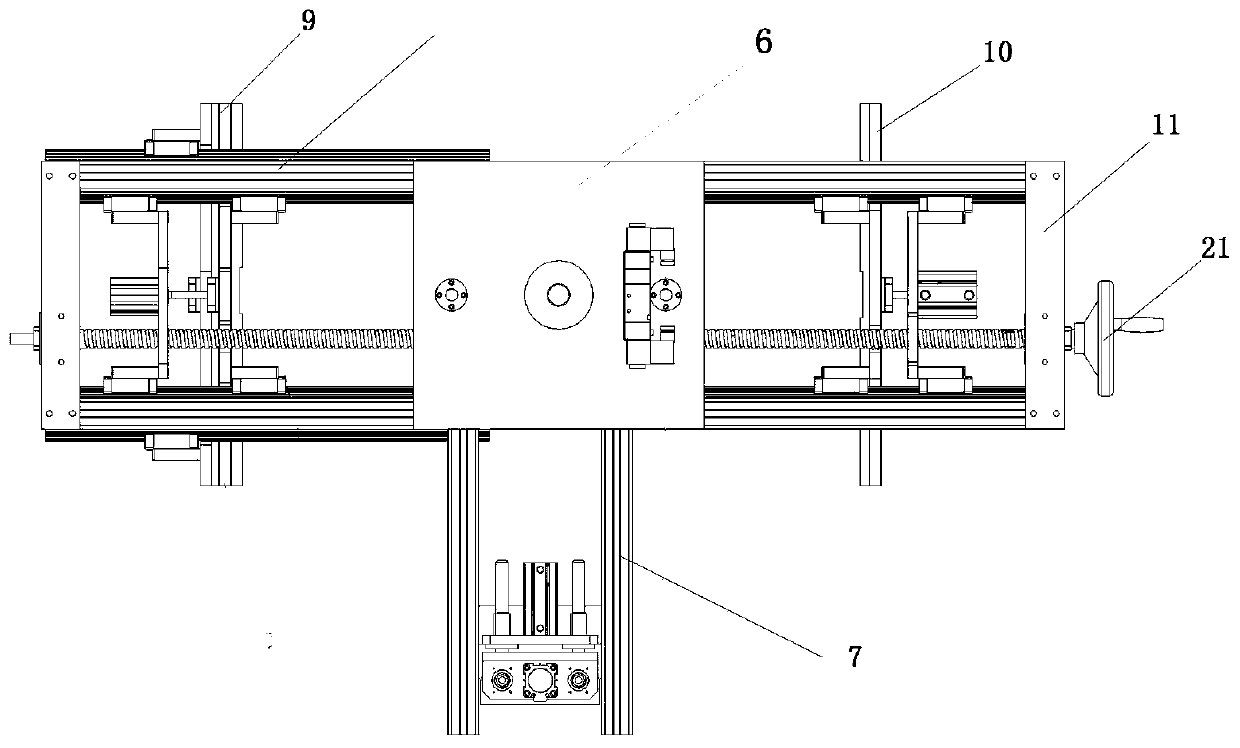

[0033] as the picture shows, figure 1 It is an overall structural diagram of a preferred embodiment of the present invention, figure 2 , 3 respectively figure 1 top and front views of the Figure 4 for image 3 As can be seen from the figure, the fixture includes: a mounting bracket, the mounting bracket used in this embodiment is two parallel profile brackets 1, the two ends of the two profile brackets 1 are connected by a connecting plate 11, the connection The plate 11 is clamped on the profile bracket 1 and can move along the profile bracket 1; a screw 2 is arranged on the mounting bracket, the screw here is two-stage, and one end of the left screw is fixed on the connecting plate 11, The other end is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com